Motor winding machine

A technology of winding machine and winding device, which is applied in the field of production equipment for motor stators, can solve problems such as coil slack, affecting product quality and production efficiency, and coil tension can not be well controlled, so as to achieve production quality Good, easy operation and post-maintenance, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

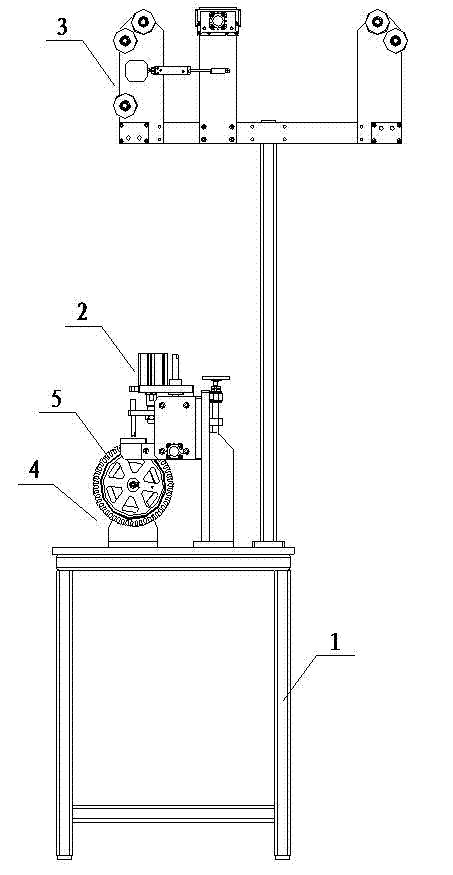

[0028] Such as figure 1 As shown, the embodiment of the present invention is a motor winding machine, including a working platform 1, a winding device 2, a tensioning device 3 and a stator rotating device 4, and the winding device 2, the tensioning device 3 and the stator rotating device 4 are set On the working platform 1, the stator rotating device 4 is arranged on one side of the winding device 2, and the tensioning device 3 is arranged on the upper end of the winding device 2 through a pole.

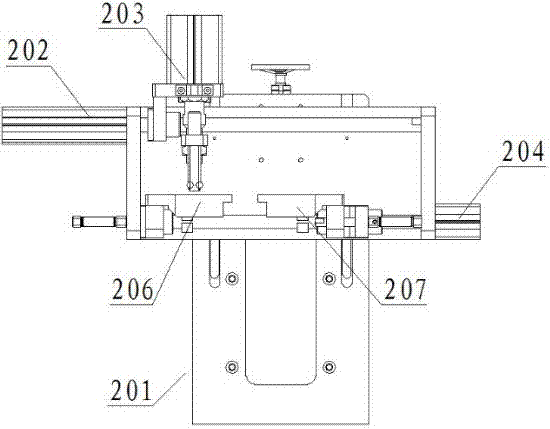

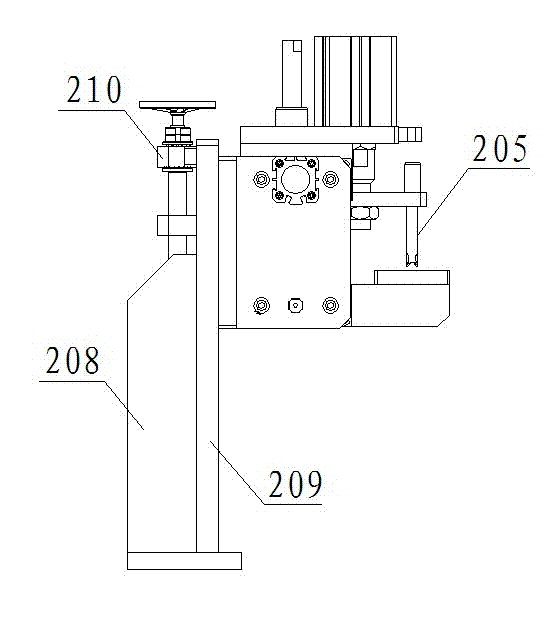

[0029] Such as figure 2 and image 3 As shown, the winding device 2 includes an adjustment bracket 201, a cylinder, a wire guide plate and a wire nipple 205, the upper and lower ends of the notch of the wire guide plate are V-shaped openings, the outlet of the wire nipple is a V-shaped mouth, and the cylinder includes a laterally moving cylinder 202, the longitudinal movement cylinder 203 and the movement cylinder 204, the transverse movement cylinder 202 is arranged on one end of...

Embodiment 2

[0035] The rest are the same as in Embodiment 1, the difference is that it also includes a PLC system for controlling the equipment and an alarm device for monitoring the work process, the PLC system can effectively control the action of the motor winding machine to ensure work efficiency; The device can monitor the entire work project to ensure that the motor winding machine can work normally. If an abnormality occurs, the alarm device will stop the motor winding machine from working, and at the same time send an alarm to remind the staff to perform maintenance in time.

Embodiment 3

[0037] The rest is the same as the first embodiment, except that the wire hole plate 310 is provided with 6 wire holes 311 . The number of wire holes 311 can be adjusted accordingly according to the requirements of the product, so as to meet the requirements of coils in various motors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com