Device for producing large-diameter plastic connecting flange

A technology for connecting flanges and production equipment, which is applied in the field of production equipment for large-diameter plastic connecting flanges. It can solve problems such as the depression of the connecting ring, reduce the sealing performance of the upper surface of the connecting ring, and affect the production quality of the connecting flange, so as to improve the sealing. performance, the effect of increasing the amount of material injected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

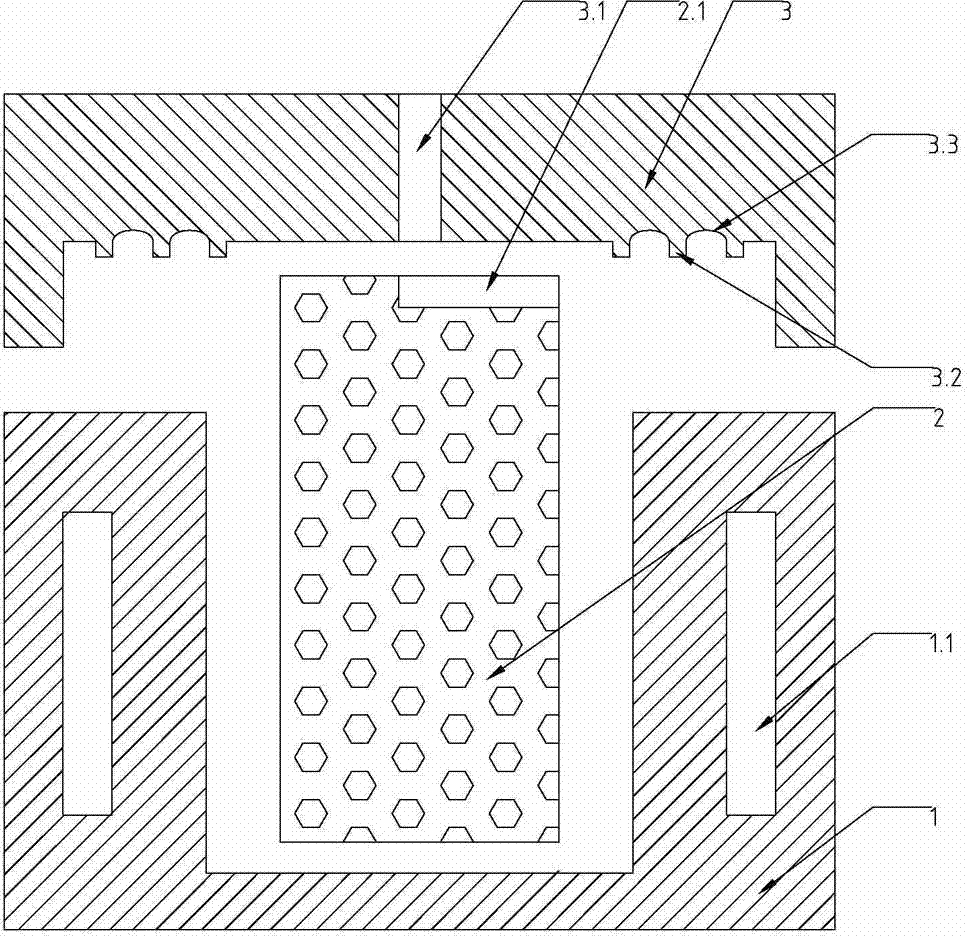

[0007] Such as figure 1 As shown, a production device for a large-diameter plastic connecting flange, which includes a housing 1, a mold core 2 and an upper cover 3, the upper cover 3 is arranged on the housing 1, and a feeding hole is arranged in the middle of the upper cover 3 The injection hole 3.1, the mold core 2 is arranged on the inner bottom surface of the shell 1, a diversion groove 2.1 is provided on the upper surface of the mold core 2 corresponding to the injection hole 3.1, and a cooling water chamber 1.1 is provided in the shell 1; The feature is that the inner surface of the upper cover 3 is provided with several annular bosses 3.2, and the inner surface 3.3 of the upper cover 3 between two adjacent annular bosses 3.2 is concave arc.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap