Tumbling-box washing machine

A drum-type washing machine, washing machine technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problem of difficulty in taking out or putting in the laundry, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

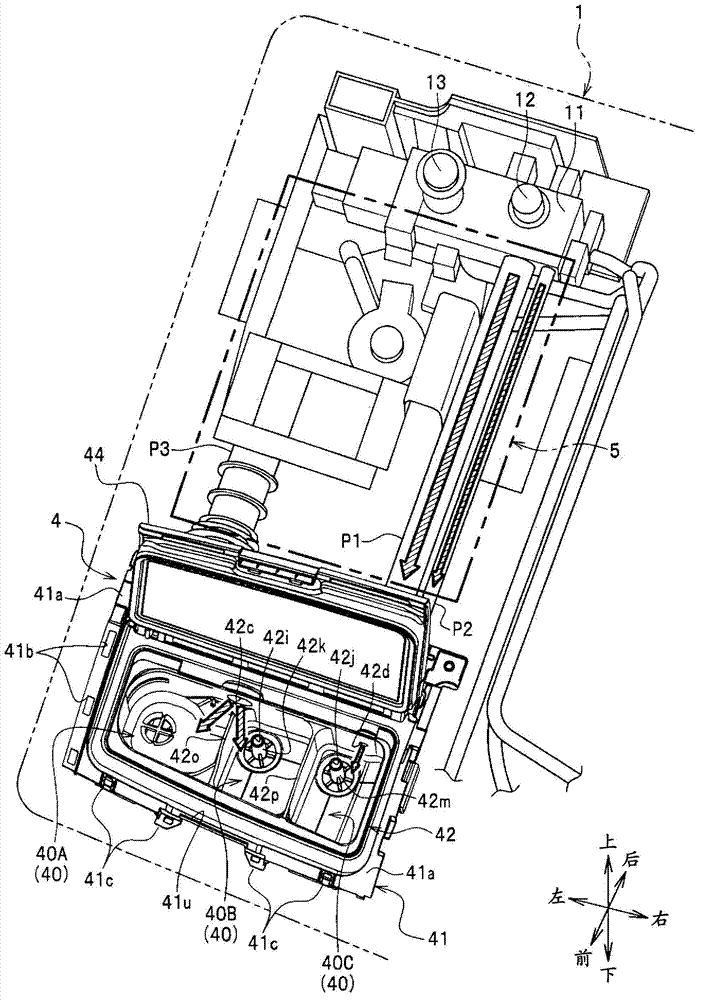

[0029] First, refer to Figure 1 to Figure 6 The first embodiment of the present invention will be described.

[0030] (Structure of washing machine)

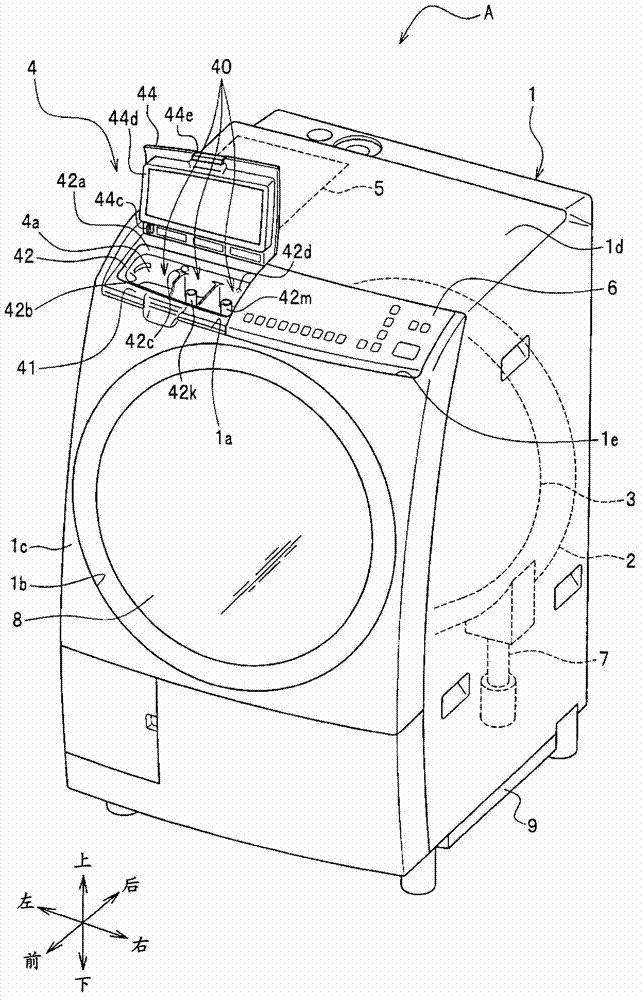

[0031] like figure 1 As shown, the washing machine A (drum-type washing machine) is the following device: a detergent input part 4 is provided on the upper surface of the cabinet 1 of the washing machine A, and a washing machine for taking out or putting in clothes and the like is provided on the front part of the cabinet 1. The clothes inlet 1b of the clothes inlet 1b, the rotation axis of the substantially cylindrical rotating drum 3 is slightly inclined, and the clothes thrown in from the clothes inlet 1b are washed by the rotation of the rotating drum 3 around its rotation axis. The washing machine A includes a cabinet 1 , an outer tank 2 , a rotary drum 3 , a detergent injection unit 4 , a water supply unit 5 , an operation panel 6 , a damper 7 , a door 8 , and the like, which will be described later.

[0032] (Structu...

no. 2 approach )

[0153] Next, refer to Figure 7 ~ Figure 13 A second embodiment of the front-loading-type washing machine B of the present invention will be described. In addition, the structure already demonstrated is attached|subjected to the same code|symbol, and the description is abbreviate|omitted.

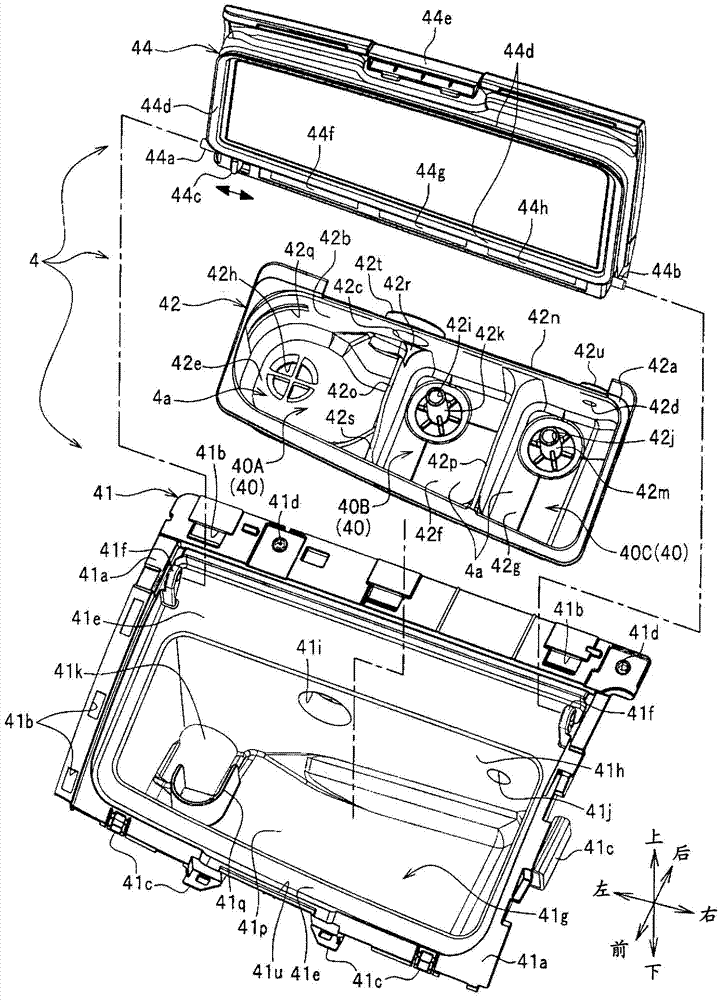

[0154] Figure 7 It is an external perspective view showing the front-loading-type washing machine according to the second embodiment of the present invention. Figure 8 It is a schematic perspective view of main parts showing the water supply path to the detergent injection part of the front-loading-type washing machine according to the second embodiment of the present invention. Figure 9 It is an exploded perspective view of the detergent injection unit of the front-loading-type washing machine according to the second embodiment of the present invention. Figure 10 It is a main part perspective view which shows the detergent injection part of the front-loading-type washing machine con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com