Combined type building seepage-proofing device for water pipes penetrating boards

A combined technology for construction, applied in buildings, sewer systems, waterway systems, etc., can solve problems such as water leakage and loose connection of drainage pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

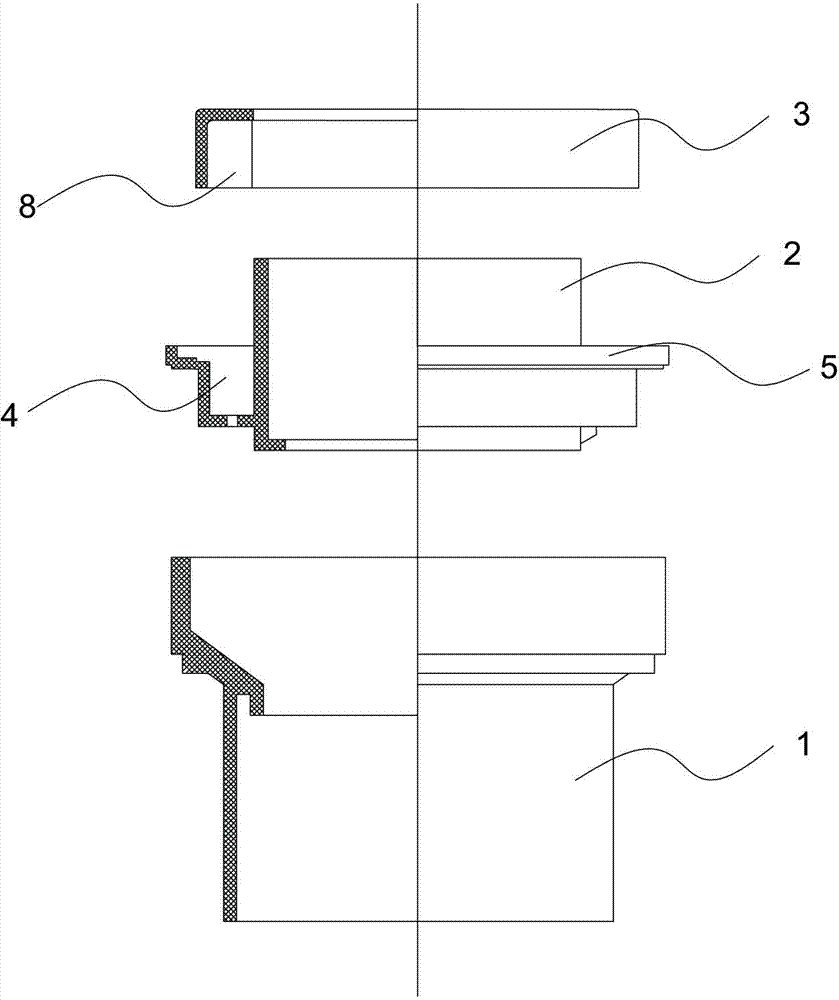

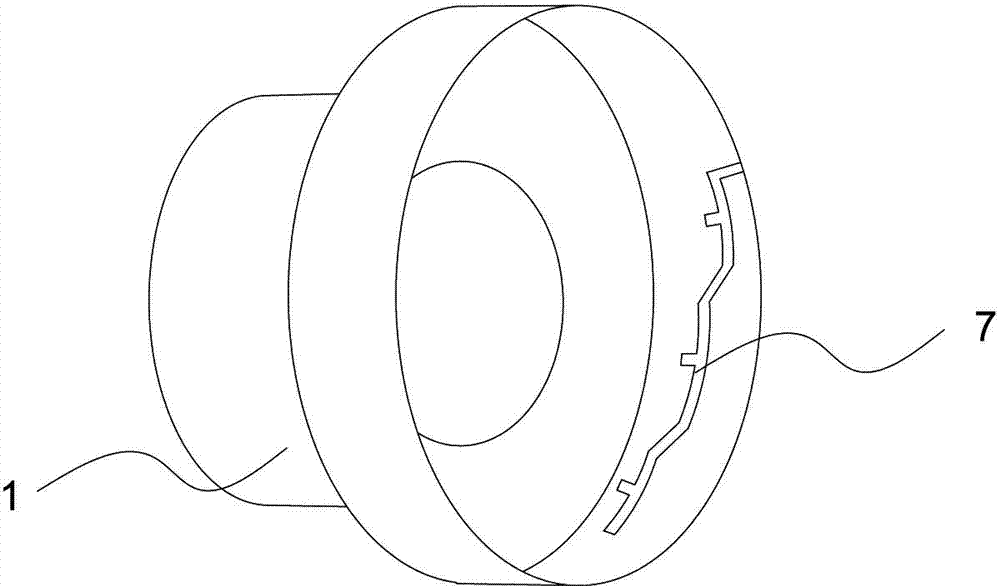

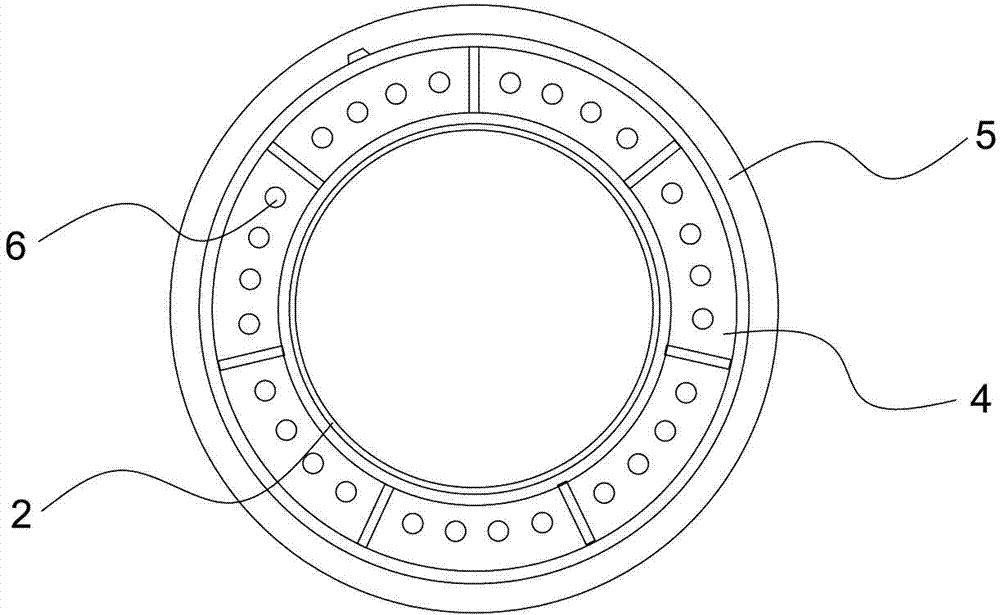

[0012] see Figure 1 to Figure 5 , The seepage preventer for combined building through-board water pipes includes a pre-embedded pipe fitting 1 for penetrating the floor slab and a water-bearing assembly, the above-mentioned parts are all made of plastic. The upper end of the pre-embedded pipe fitting 1 is provided with a bell mouth; the water receiving assembly includes a water receiving tray 2 and a dustproof cover 3, the water receiving tray 2 is a ring structure, and its lower nozzle is matched with the bell mouth of the pre-embedded pipe fitting 1. The outer circle of the water receiving tray 2 is provided with a water receiving tank 4, the outer edge of the water receiving tank 4 is provided with a water diversion slope 5, and the bottom of the water receiving tank 4 is provided with a drain hole 6 leading to the bell mouth of the pre-embedded pipe fitting; the dustproof cover 3 is ring-shaped , covering above the water tank 4, the bottom of the dust cover 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com