Universal hinge joint assembly of sealed angular contact oscillating bearing steel structure

A joint bearing and angular contact technology, which is applied in the direction of building construction and construction, can solve the problems that rigid structural stress cannot be eliminated, achieve the effect of eliminating external shear force and additional bending moment, ensuring safety, and realizing stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

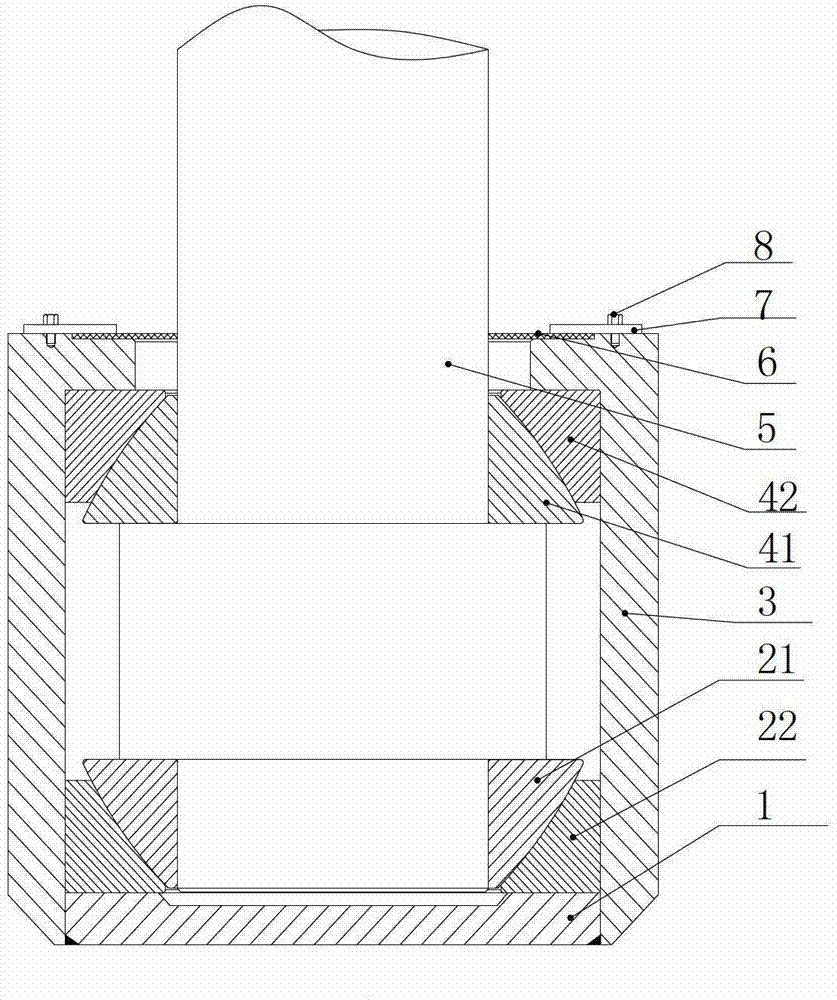

[0016] Such as figure 1 As shown, the embodiment of the present invention is provided with an upper angular contact joint bearing, a lower angular contact joint bearing, a cross mandrel 5, a steel casting 3, a bottom plate 1, bolts 8, a positioning pressure plate 7 and a sealing ring 6. The upper angular contact spherical plain bearing is provided with an upper inner ring 41 and an upper outer ring 42, and the upper inner ring 41 and upper outer ring 42 can rotate and swing relatively, and the lower angular contact spherical plain bearing is provided with a lower inner ring 21 and a lower outer ring 42. The outer ring 22, the lower inner ring 21 and the lower outer ring 22 can rotate and swing relatively, the upper inner ring 41 of the upper angular contact joint bearing is closely fitted with one end of the cross spindle 5, and the upper end of the upper angular contact joint bearing The outer ring 42 is mated with the inner hole of the steel casting 3, the lower inner ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com