Method for creating internal dumping conditions of strip mine

An internal dumping and open-pit mine technology, applied in open-pit mine mining, earthwork drilling, special mining, etc., can solve the problems of short strike length, large inclination extension, and small distribution range, and save transportation costs and transportation distances. The effect of the recent and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

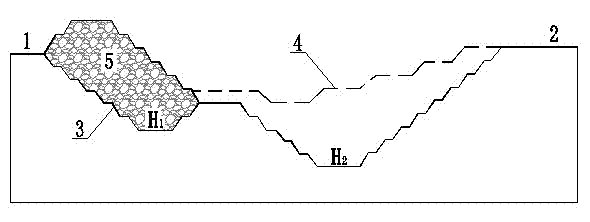

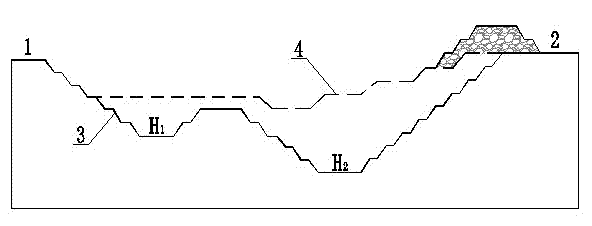

[0020] Below with reference to the accompanying drawings, a method for creating soil discharge conditions in an open-pit mine of the present invention will be further described in detail by describing the embodiments.

[0021] As shown in the figure, the Gushan iron ore deposit is buried relatively shallow, with a large extension on the west side and a relatively shallow extension on the east side; it is semi-circular in the horizontal direction, and is disconnected by rock mass in the south. Therefore, the minimum mining elevations at the east and west ends of the designed open-pit boundary are different, and the minimum mining elevation in the east (H 1 )-106m, the lowest mining elevation in the west (H 2 ) - 166m.

[0022] According to the current mining situation of the Gushan stope, if the east and west ends are mined at the same time, there will be no place for the stripped rock and soil to be discharged. Therefore, optimize and adjust the stripping position of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com