High-concentration full-tailing self-flow filling cementing material for phosphate rock mountain

A cementitious material and high-concentration technology, which is applied in the field of mine filling, can solve the problems of inability to take into account the consumption of phosphorous chemical solid waste of beneficiation tailings, inability to solve the problems of filling and topping, and the strength of mildew is significantly improved, so as to achieve low material cost, Low cost and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

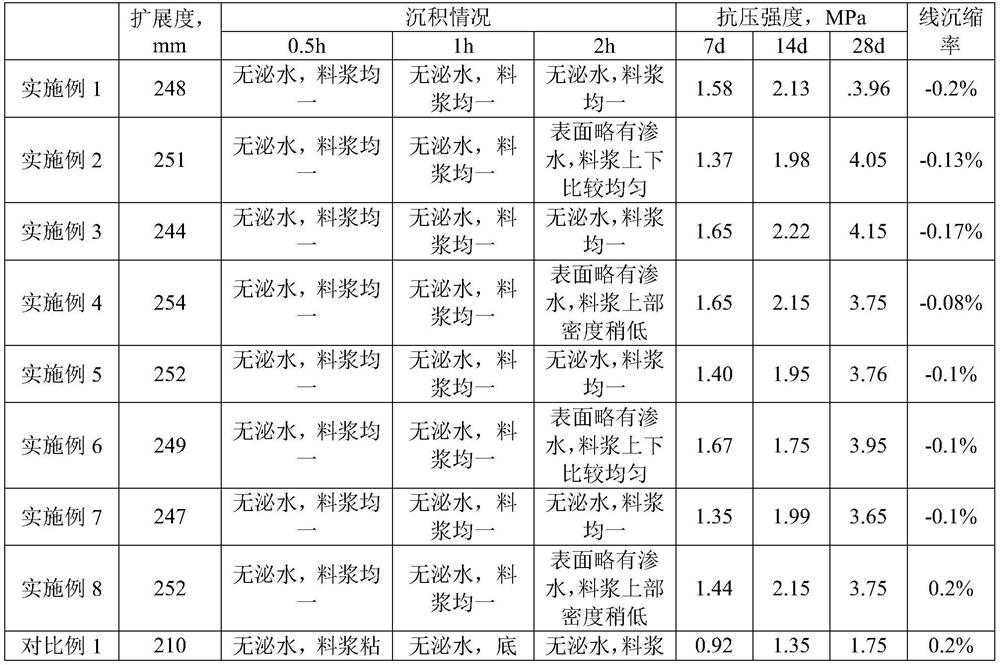

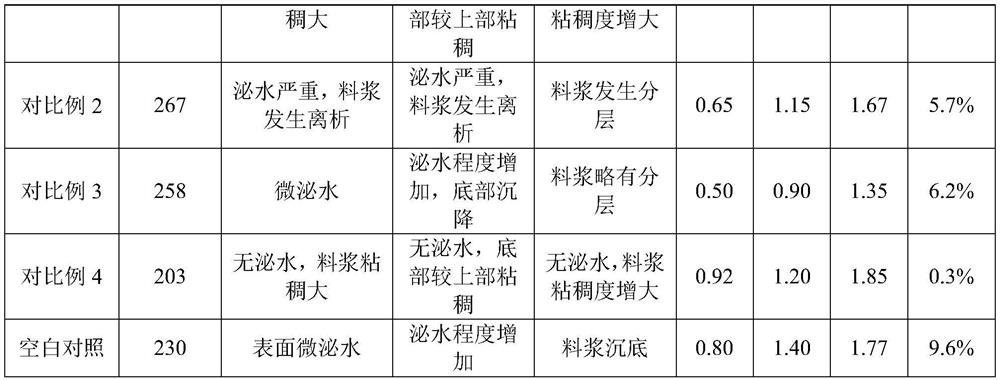

Examples

Embodiment 1

[0034] The high-concentration full tailings self-flowing cementitious material for phosphate mine provided in this embodiment includes raw materials including 35wt% of phosphogypsum, 36wt% of phosphorus slag powder, 12wt% of cement, 13wt% of alkaline activator, 1.5wt% of air-entraining component, Modified vegetable gum 2.5wt%.

[0035] The preparation method of modified plant gum is:

[0036] S1. Weigh xanthan gum and polyethylene glycol monomethyl ether methacrylate (MPEGMA, esterified monomer) according to the molar ratio of 7:1, and add water to prepare a 50% aqueous solution;

[0037] S2. Dissolve sodium methacryloyl sulfonate in water to prepare an aqueous solution with a concentration of 40-53%, add it to the aqueous solution prepared in step S1 and stir to form a mixed solution; and sodium methacryloyl sulfonate and esterification monomer The ratio of the amount of MPEGMA substances is 1:1;

[0038] S3. Under a nitrogen atmosphere, the mixed solution prepared in step ...

Embodiment 2

[0041] The high-concentration full tailings self-flowing filling cementitious material for phosphate mines provided in this example differs from Example 1 in that the raw materials include 40wt% phosphogypsum, 30.5wt% phosphorus slag powder, 10wt% cement, and 15wt% alkaline activator %, air-entraining component 1.5wt%, modified vegetable gum 3wt%.

Embodiment 3

[0043] The high-concentration full tailings self-flowing filling cementitious material for phosphate mines provided in this example differs from Example 1 in that the raw materials include 24.5wt% of phosphogypsum, 40wt% of phosphorus slag powder, 18wt% of cement, and 15wt of an alkaline activator. %, air-entraining component 1.5wt%, modified vegetable gum 1wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com