Reciprocating motion device for container goods flat pallet in carriage

A technology of reciprocating movement and flat pallets, applied in the direction of vehicles, motor vehicles, transport objects, etc. for freight transportation, which can solve the problem of labor-intensive manual pallet trucks, difficult loading and unloading of palletized goods, and inability to carry double-sided flat pallets. Work and other problems, to achieve the effect of many loading and unloading points, simple structure and high loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

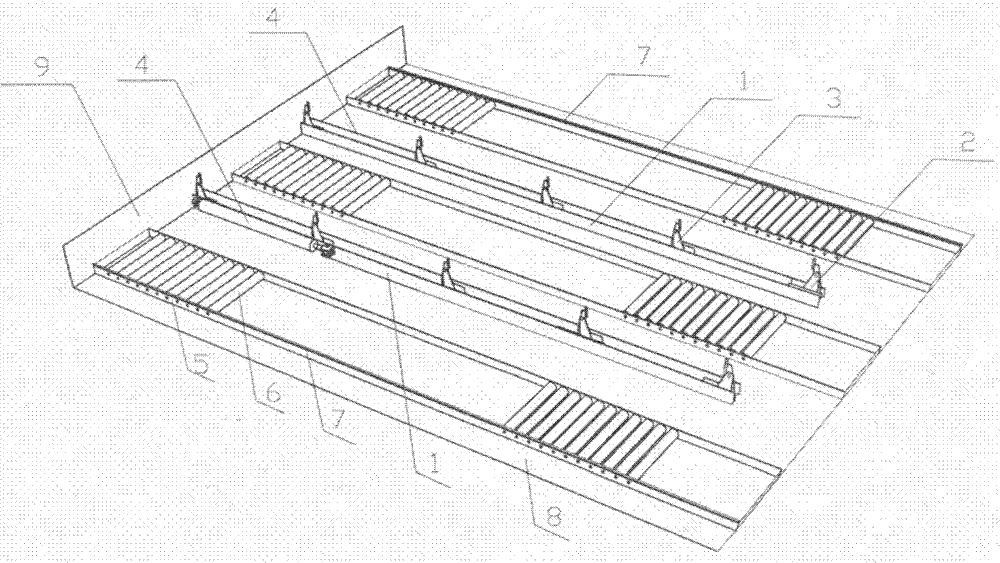

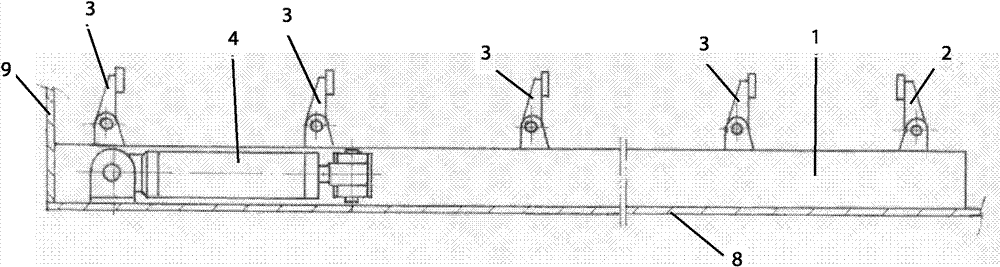

[0047] Such as figure 1As shown, it is the first embodiment of the reciprocating device for flat pallets of containerized goods used in the compartment of the present invention. The bottom plate 8 of the compartment is provided with three rows of rollers 5, the rollers 5 extend along the longitudinal direction of the compartment, and the rollers 5 There are rollers 6 for rolling flat pallets of goods on the top, push-pull rods 1 that can move relative to the bottom plate 8 are arranged between two adjacent roller tables 5, and four sets of unloading grabs are arranged on each row of push-pull rods 1. Board grab 3 and a board grab 2 for assembled vehicles, the unloading grab board 3 is used to push the flat pallet of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com