Heating pump for paraffin

A technology of paraffin wax and pump body, which is applied in the direction of pumps, pump components, and parts of pumping devices for elastic fluids. The effect of simplicity and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

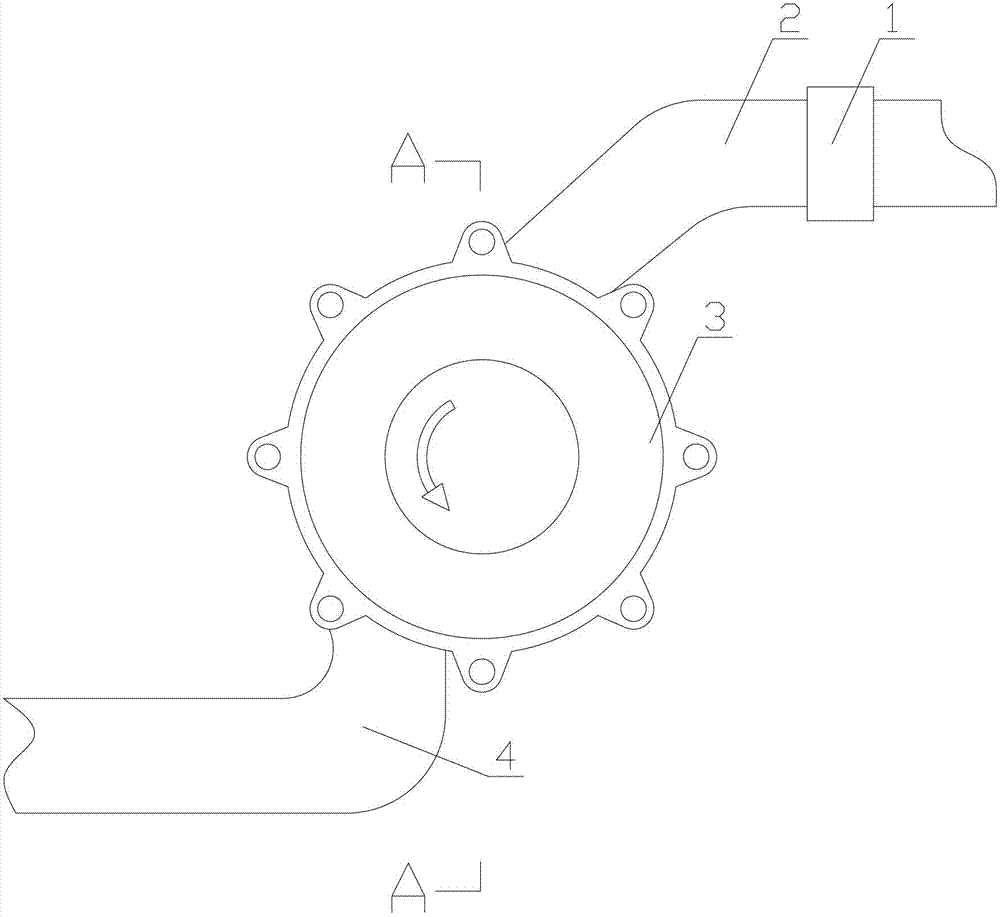

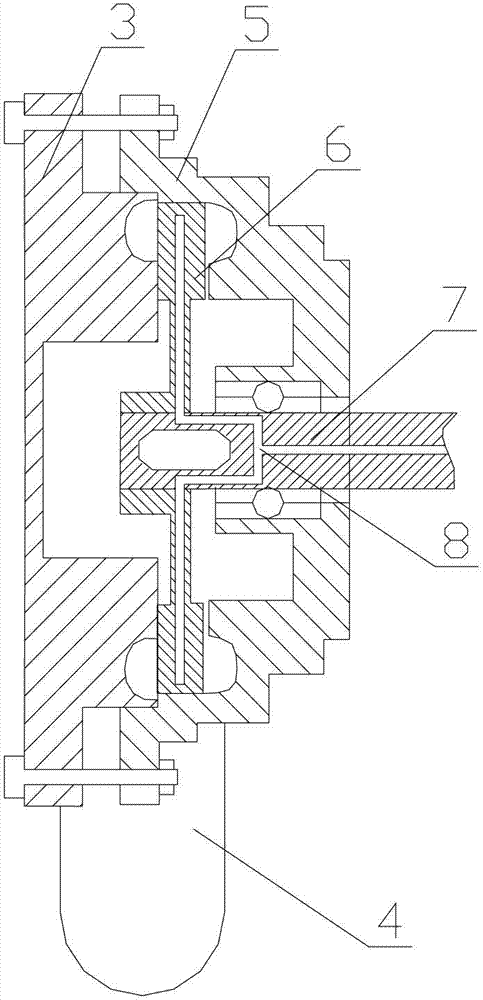

[0018] The specific embodiment of the present invention is shown in the accompanying drawings. The heat pump for paraffin is composed of a pump body 5, a pump cover 3, a pump shaft 7, an impeller 6, a wax inlet pipe 2 and a wax outlet pipe 4; it is characterized in that the pump shaft 7 Installed on the bearing 9 in the middle of the pump body 5; the impeller 6 is installed on the front end of the pump shaft 7; the inside of the impeller 6 and the pump shaft 7 is equipped with an electric heating tube 8, and the heating tube 8 is connected to the heating device outside the pump body 5 ; The wax inlet pipe 2 and the wax outlet pipe 4 are installed on the pump body 5; the pump cover 3 is installed on the pump body 5 through bolts.

[0019] The wax inlet pipe 2 is installed above the pump body 5, and the wax outlet pipe 4 is installed below the pump body 5.

[0020] A valve 1 is housed on the wax inlet pipe 2 .

[0021] The above is only a preferred embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com