Double-lip sealing type four-point contact ball turntable bearing

A four-point contact, slewing bearing technology, applied in the direction of ball bearings, bearing components, shafts and bearings, to achieve the effects of preventing internal grease leakage, improving radial rated dynamic load and rated static load capacity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

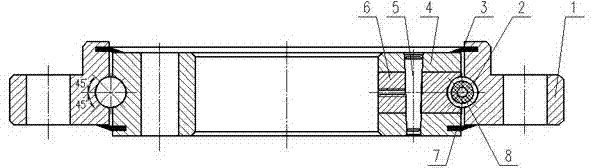

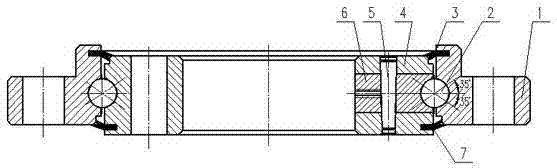

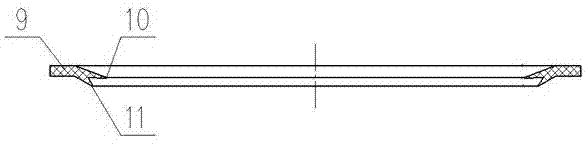

[0019] like figure 2 As shown, a double-lip seal type four-point contact ball slewing bearing, the four-point contact ball slewing bearing includes an inner ring 4, an outer ring 1 and steel balls 2; an upper sealing ring 3 and a lower sealing ring 7 are provided ; The upper sealing ring 3 and the lower sealing ring 7 are ring structures of double-lip seals; the bodies 9 of the upper sealing ring 3 and the lower sealing ring 7 all have a sealing function protruding inwardly or outwardly. The two lips are lip I10 and lip II11; the bodies of the upper sealing ring 3 and the lower sealing ring 7 are located in the sealing groove of the outer ring 1 or inner ring 4, and the lip I10 rests on the inner ring 4 Or the end face of the outer ring 1 plays the role of axial sealing; the lip II11 rests on the outer diameter surface of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com