Elastic rubber type check valve for multi-dust environment

A kind of elastic glue, one-way valve technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

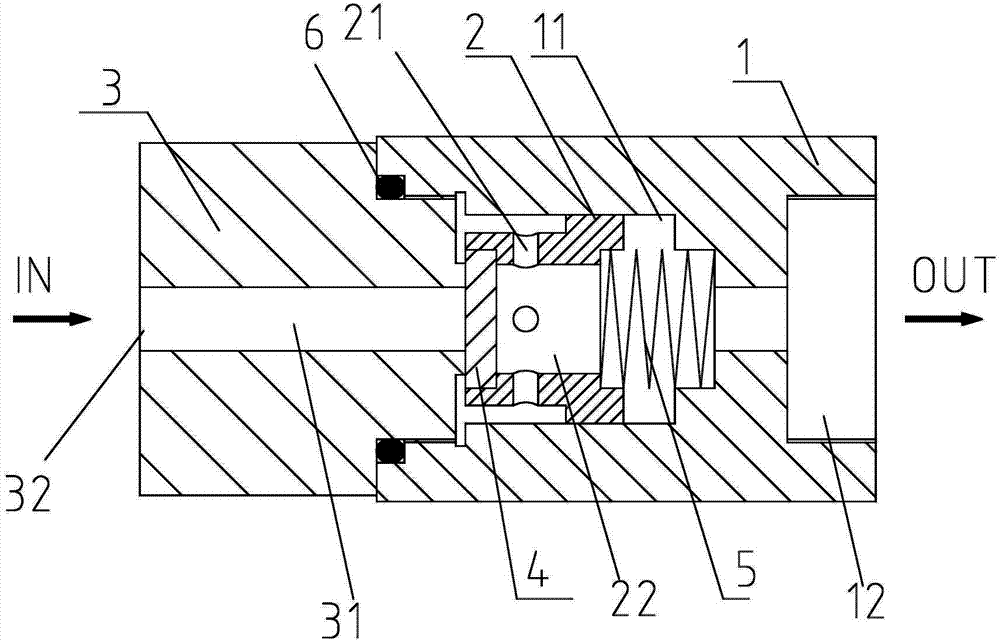

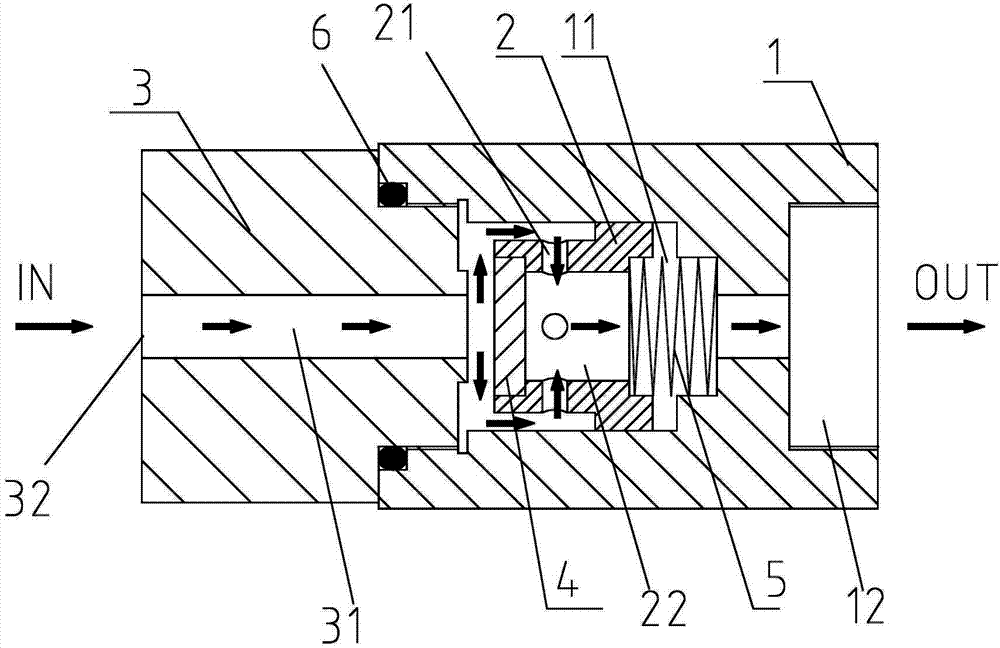

[0029] like Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, an elastic hose type check valve used in a dusty environment, including:

[0030] A valve body 10, a cavity 101 is arranged inside, an installation port 102 is formed at one end of the valve body 10 to communicate with the cavity 101, and an output port 103 is arranged on the other end of the valve body 10, and the output port 103 communicates with the cavity 101;

[0031] A valve core 20, the front end of the valve core 20 extends into the cavity 101 of the valve body 10 from the installation port 102, the installation port 102 of the valve body 10 is blocked, and the valve core 20 is provided with an air flow channel 201; The inlet 203 of the channel 201 is located at the tail of the valve core 20, and the outlet 202 of the air flow channel 201 is located at the front end;

[0032] An elastic rubber tube 30, the elastic rubber tube 30 is set on the front end of the valve core 20 to block the outlet 202...

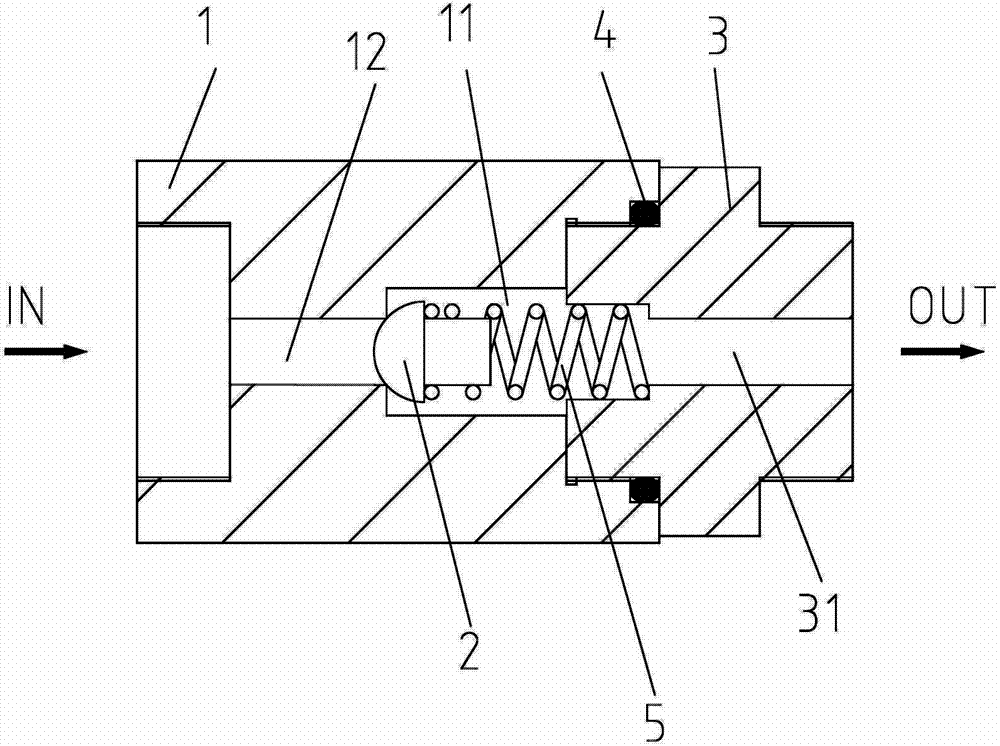

Embodiment 2

[0038] This embodiment is an improvement on Embodiment 1, such as Figure 9As shown, an elastic hose type check valve used in a dusty environment includes: a valve body 10, a cavity 101 is arranged inside, and an output port 103 is arranged on one end of the valve body 10, and the output port 103 is connected to the cavity 101 connected; a spool 20, the spool 20 extends into the cavity 101 of the valve body 10, the installation port of the valve body 10 is blocked, and the spool 20 is provided with an air flow channel 201; the inlet 203 of the air flow channel 201 Located at the tail of the spool 20, the outlet 202 of the airflow channel 201 is located at the front end; an elastic rubber tube 30, which is sleeved on the front end of the valve core 20 to block the outlet 202 of the airflow channel 201; when the inlet 203 of the airflow channel 201 When compressed air enters, the compressed air reaches the elastic hose 30 from the outlet 202 of the airflow passage 201, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com