Method for measuring object surface topography

A technology for the surface and shape of an object, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of small measurement range and harsh measurement conditions, and achieve the effects of improving imaging sensitivity, high-resolution imaging, and high-resolution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

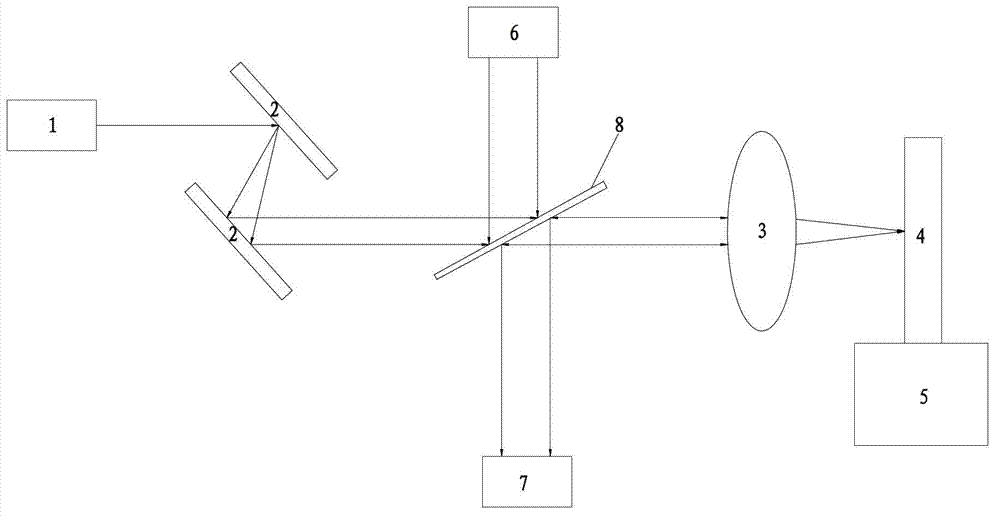

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] Firstly, the carrier envelope phase and repetition frequency of the optical comb 1 at the transmitting end and the optical comb 6 at the local oscillation end are precisely locked at the same time. Let the two optical combs have a small repetition frequency difference, and lock the two optical combs on the same frequency standard at the same time, so as to ensure the minimum relative frequency jitter between the two optical combs. The optical comb 6 at the local oscillation end uses a femtosecond laser comb light source, which has good spatial coherence and directionality, and can be directly contactless and without damaging the surface of the measured object. At the same time, the frequency uncertainty of the optical comb light source is small, which can ensure Accuracy and precision of measurements.

[0021] Then, using the spatial chirp tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com