Device and method for moving, lifting and rotating industrial X-ray detection machine

A technology of X-ray and flaw detectors, which is applied in the fields of electromechanical equipment, rotation, lifting, and movement of industrial X-ray flaw detectors. It can solve the problems of high labor intensity, low work efficiency, and rework, so as to reduce labor intensity, improve work efficiency, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

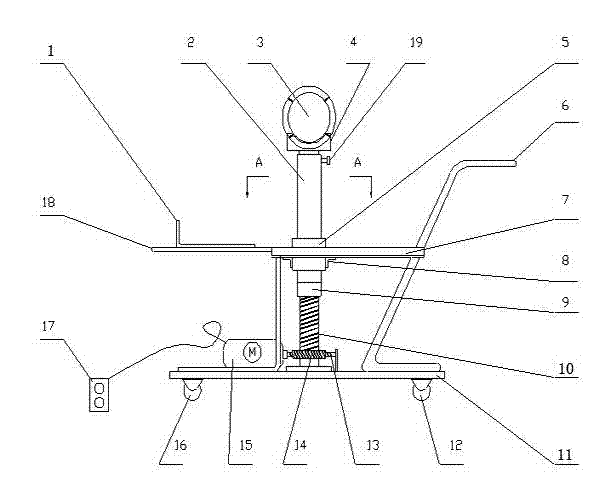

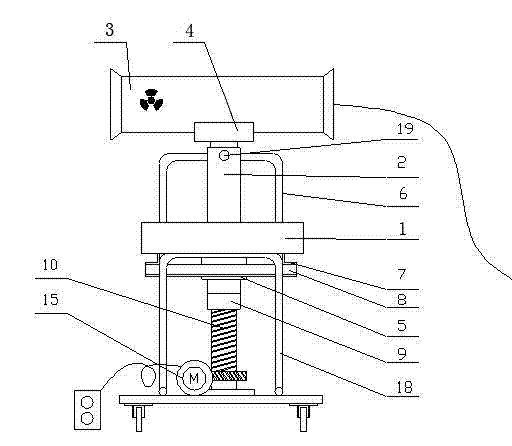

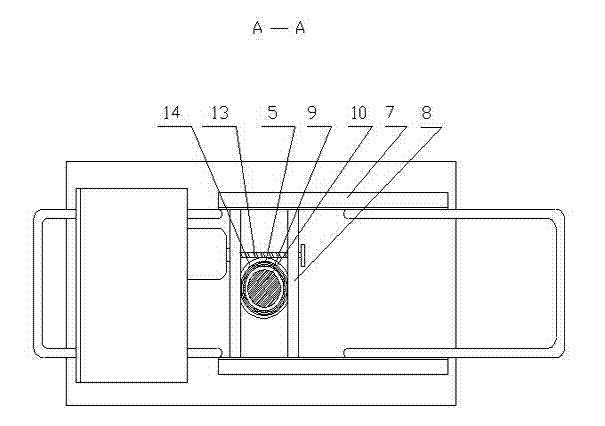

[0016] In an embodiment, a device for moving, lifting, and rotating an industrial X-ray flaw detector includes a skeleton, a lifting cylinder 2, an industrial X-ray flaw detector 3, a X-ray machine holder 4, a fixed cylinder 5, and an internally threaded sleeve 9. Lifting lead screw 10, transmission lead screw 13, reversing gear 14, single-phase capacitor starter motor 15 and controller 17. The rear end of the skeleton is provided with universal wheels 12, which can rotate within 360°. There are directional wheels 16, which can move forward and backward. The fixed cylinder 5 is set on the outside of the lifting cylinder 2, and is fixedly connected with the skeleton by welding to prevent shaking or rollover after loading the X-ray machine. The industrial X-ray flaw detector 3 is placed in the X-ray machine clamp On the seat 4, the lower end of the X-ray ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap