Oil-resistant sealing tank device for rubber test and manufacture method of oil-resistant sealing tank device

A sealed tank and oil-resistant technology, which is applied in the field of rubber test utensils, can solve the problems of unsatisfactory sealing tank, loss of sealing performance, test failure, etc., to improve accuracy and convenience, improve sealing performance, and ensure accuracy and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

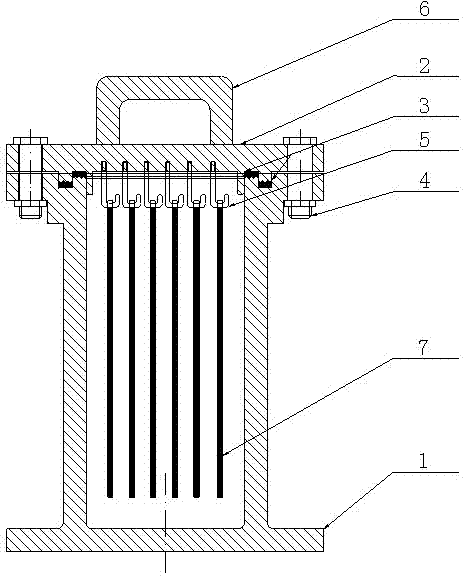

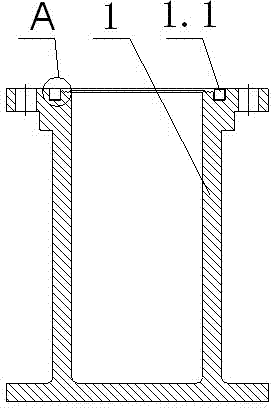

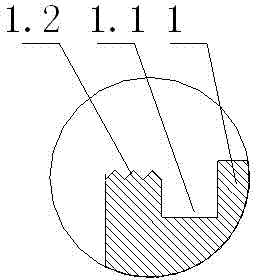

[0016] Embodiments of the present invention: when implementing a method for making an oil-resistant sealed tank device for rubber testing of the present invention, the oil-resistant sealed tank 1 and the sealed tank cover 2 are preferably made of stainless steel. When making the oil-resistant sealed tank 1 , make a circle of sealing ring groove 1.1 for placing the sealing ring 3 on the end face of the tank mouth, and make a zigzag end face groove on the tank mouth end face between the cavity of the oil-resistant sealed tank 1 and the sealing ring groove 1.1 at the same time 1.2, make an annular boss 2.1 on the sealing lid 2 of the oil-resistant sealed tank 1, so that the annular boss 2.1 can be inserted into the cavity of the oil-resistant sealed tank 1, and at the same time make a ring seal on the sealed tank lid 2 Ring pressure ring 2.2, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com