Microcement laminate and related production method

A technology of ultra-fine cement and laminates, applied in chemical instruments and methods, layered products of hydraulic materials, coatings, etc., can solve problems such as laboriousness, and achieve the effects of optimized working time, favorable quality, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] DESCRIPTION OF THE PREFERRED EMBODIMENT

[0048] The preferred embodiments indicated below are provided by way of non-limiting, illustrative purposes for a better understanding of the invention.

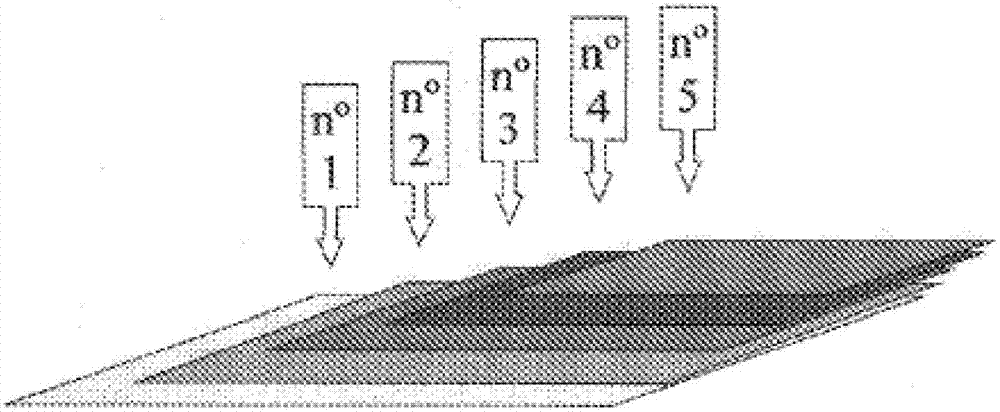

[0049] Ultrafine cement laminates can be prepared as follows:

[0050] Based on a fiberglass hood, allow it to impregnate the copolymer and leave to dry for 4 hours. Apply a layer of polymer microcement by hand using a trowel, leave to dry, and smooth the interlayer with 240-grit sandpaper. Apply a sealer made of acrylic copolymer using a roller and leave to dry for 2 hours. Finish the surface with two coats of water-based two-component polyurethane, allowing for a 4-hour interlayer dry. Laminate the visible side with a protective film while the varnish is completely dry. Using this exemplary method, a cementitious sheet is obtained, the thickness and size of which can be varied as desired, which is used to coat floors, walls, columns, stairs, trim, or other porous or non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com