Preparation method of dental restoring resin taking silicon dioxide and cluster of silicon dioxide as stuffing

A technology of silica and dental restoration, which is applied in the field of preparation of dental restoration materials, can solve the problems of affecting the aesthetic performance of resin, unfavorable large-scale production, expensive reagents, etc., and achieves good wear resistance and simple preparation method , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Table 1 Composite resin components and the content of each component

[0039] components

Mass fraction (wt%)

Bis-GMA

14.85

TEGDMA

14.85

CQ

0.06

4-EDMAB

0.24

Silanized silica

35

Silanized silica clusters

35

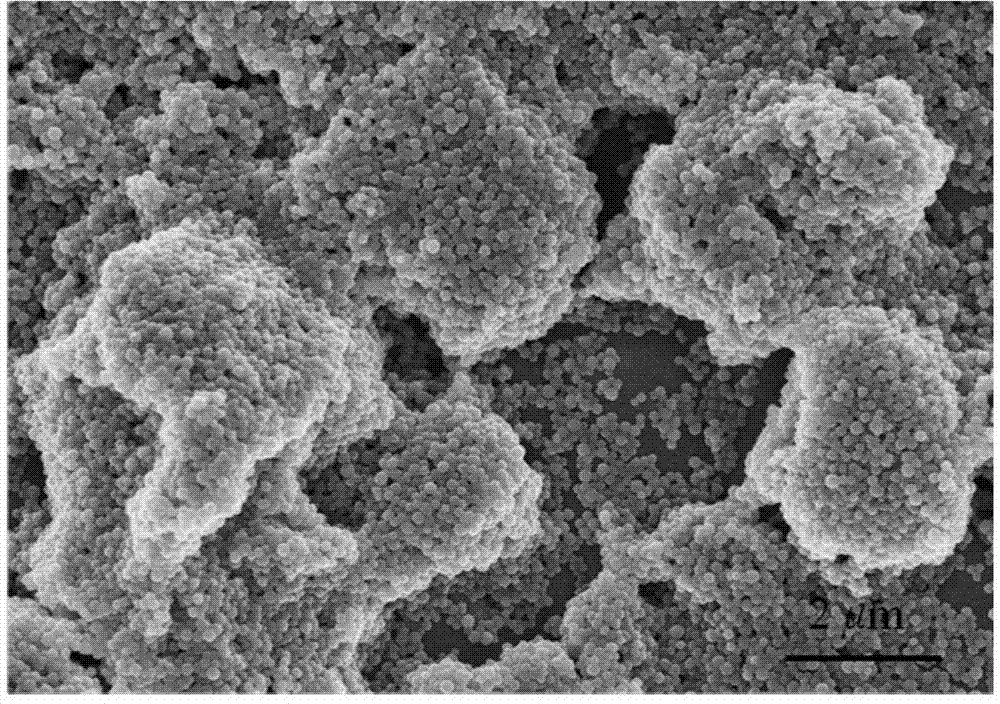

[0040] (1) Preparation of silica nanoclusters

[0041] a Preparation of functionalized nano-silica

[0042] Disperse two parts of 5.0g nano-silica (particle size: 20~100nm) into ethanol respectively, add 0.5mL coupling agent containing amino group (γ-aminopropyltriethoxysilane) and 0.5mL containing carboxyl group Coupling agent (3-(3-carboxyacrylamido)propyltriethoxysilane) for functional modification, mechanically stirred overnight at 65°C, centrifuged separately after the reaction, and then ethanol and deionized water Washing and vacuum drying at 60° C. for 16 h to obtain amino-functionalized silica and carboxyl-functionalized silica respectively.

[0043] b Preparation of sil...

Embodiment 2

[0051] Table 2 Composite resin components and the content of each component

[0052] components

Mass fraction (wt%)

Bis-GMA

14.85

EBPADMA

14.85

2,3-Butanedione

0.06

N,N-Dimethylaniline

0.24

Silanized silica

40

Silanized silica clusters

30

[0053] (1) Preparation of silica nanoclusters

[0054] a Preparation of functionalized nano-silica

[0055] Disperse two parts of 5.0g nano-silica (particle size: 20~100nm) into ethanol respectively, add 0.5mL coupling agent containing amino group (γ-aminopropyltriethoxysilane) and 0.5mL containing carboxyl group Coupling agent (3-(3-carboxyacrylamido)propyltriethoxysilane) for functional modification, mechanically stirred overnight at 65°C, centrifuged separately after the reaction, and then ethanol and deionized water Washing and vacuum drying at 60° C. for 16 h to obtain amino-functionalized silica and carboxyl-functionalized silica respectively.

[...

Embodiment 3

[0064] Table 3 Composite resin components and the content of each component

[0065] components

Mass fraction (wt%)

Bis-GMA

14.85

UDMA

14.85

CQ

0.06

N,N-Methylaniline

0.24

Silanized silica

50

Silanized silica clusters

20

[0066] (1) Preparation of silica nanoclusters

[0067] a Preparation of functionalized nano-silica

[0068] Disperse two parts of 5.0g nano-silica (with a particle size of 20-100nm) into ethanol respectively, add 0.5mL of amino-containing coupling agent (γ-aminopropyltriethoxysilane) and 0.5mL of ring-containing Oxygen coupling agent (γ-glycidyl ether oxypropyltrimethoxysilane) for functional modification, mechanically stirred overnight at 65°C, centrifuged after the reaction, washed with ethanol and deionized water, 60°C C was dried in vacuum for 16 hours to obtain amino-functionalized silica and epoxy-functionalized silica, respectively.

[0069] b Preparation of silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com