Compound antirust packaging material and manufacturing method thereof

A technology of anti-rust packaging materials and manufacturing methods, applied in the field of packaging materials, can solve problems such as mechanical corrosion of equipment, reduction of anti-rust packaging effects, and impact on product anti-rust functions, and achieve low cost, increased protection, and superior anti-rust effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

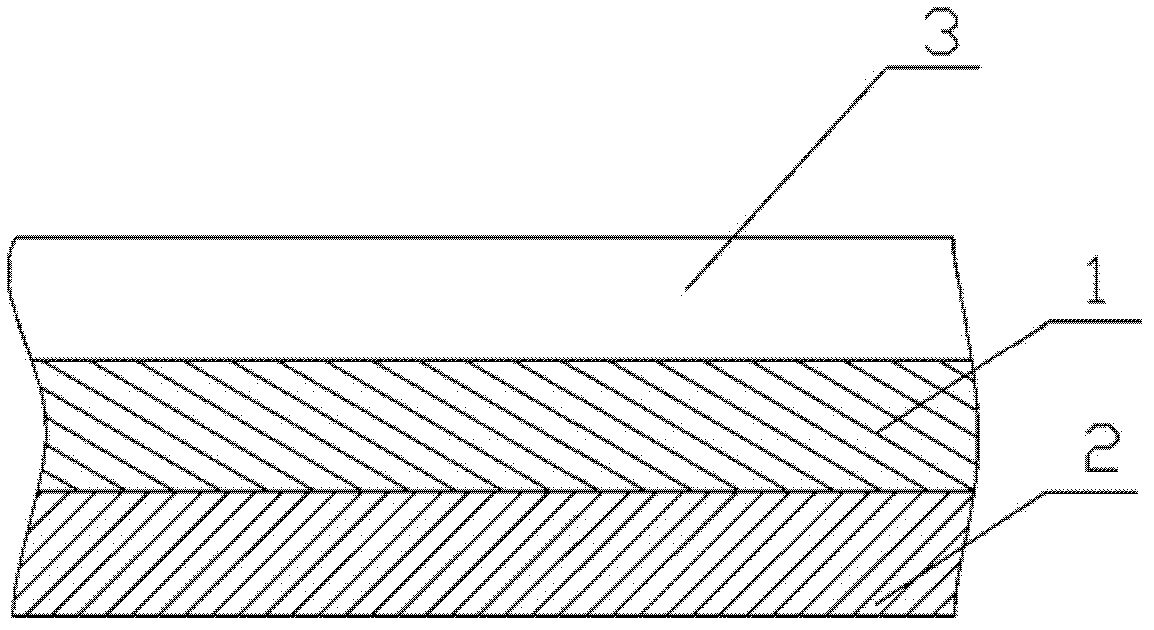

[0029] It is composed of three-layer structure, and the inner layer of wood pulp spunlace non-woven fabric is 45g / m2. 2 ;The quantitative of the middle hot melt adhesive layer is 10g / m 2 ; The thickness of the outer polymer heat shrinkable film is 150 μm.

[0030] The middle hot-melt adhesive layer is composed of hot-melt adhesive and anti-rust gas phase corrosion inhibitor; the hot-melt adhesive used is EVA hot-melt adhesive, and its product form is solvent-free type, and the mass percentage of components is 95%; the anti-rust adhesive is 95%. The mass percentage of the gas phase corrosion inhibitor component is 5%. The gas phase corrosion inhibitor is composed of: 1 part of benzotriazole; 2 parts of sodium benzoate, 1 part of sodium acetate; 1 part of sodium nitrite;

[0031] The material of the outer polymer heat-shrinkable film includes base resin, anti-aging agent and anti-rust gas phase corrosion inhibitor; the base resin is LDPE, and its component mass percentage is 9...

Embodiment 2

[0038] It is composed of three-layer structure, and the inner layer of wood pulp spunlace non-woven fabric is 65g / m2. 2 ;The quantitative of the middle hot melt adhesive layer is 15g / m 2 ; The thickness of the outer polymer heat shrinkable film is 180 μm.

[0039] The middle hot-melt adhesive layer is composed of hot-melt adhesive and anti-rust gas phase corrosion inhibitor; the hot-melt adhesive used is EVA hot-melt adhesive, and its product form is solvent-free type, and the mass percentage of components is 95%; the anti-rust adhesive is 95%. The mass percentage of the gas phase corrosion inhibitor component is 5%. The composition of the gas phase corrosion inhibitor is as follows: the composition of the gas phase corrosion inhibitor is: 2 parts of imidazole; 1 part of sodium stearate, 1 part of potassium cinnamate; 1 part of sodium nitrite;

[0040] The material of the outer polymer heat-shrinkable film includes base resin, anti-aging agent and anti-rust gas phase corrosi...

Embodiment 3

[0048] It is composed of three-layer structure, and the inner layer of wood pulp spunlace non-woven fabric is 30g / m3. 2 ;The quantitative of the middle hot melt adhesive layer is 5g / m 2 ; The thickness of the outer polymer heat shrinkable film is 150 μm.

[0049] The middle hot-melt adhesive layer is composed of hot-melt adhesive and anti-rust gas-phase corrosion inhibitor; the hot-melt adhesive used is EVA hot-melt adhesive, and its product form is solvent-free type, and the component mass percentage is 95%; the anti-rust adhesive is 95%. The mass percentage of the gas phase corrosion inhibitor component is 5%. The gas phase corrosion inhibitor is composed of: 1 part of methylbenzene triazole; 1 part of 2-methylimidazoline; 2 parts of sodium benzoate; 1 part of sodium molybdate;

[0050] The material of the outer polymer heat-shrinkable film includes base resin, anti-aging agent and anti-rust gas phase corrosion inhibitor; the base resin is LDPE, and its component mass perc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com