Low-carbon methanol gasoline composite additive and preparation method thereof

A compound additive, methanol gasoline technology, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of methanol gasoline not achieving normal use effect, power decline, difficult to start, etc., to promote combustion rate and thermal efficiency. The effect of lifting, improving power and easy starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

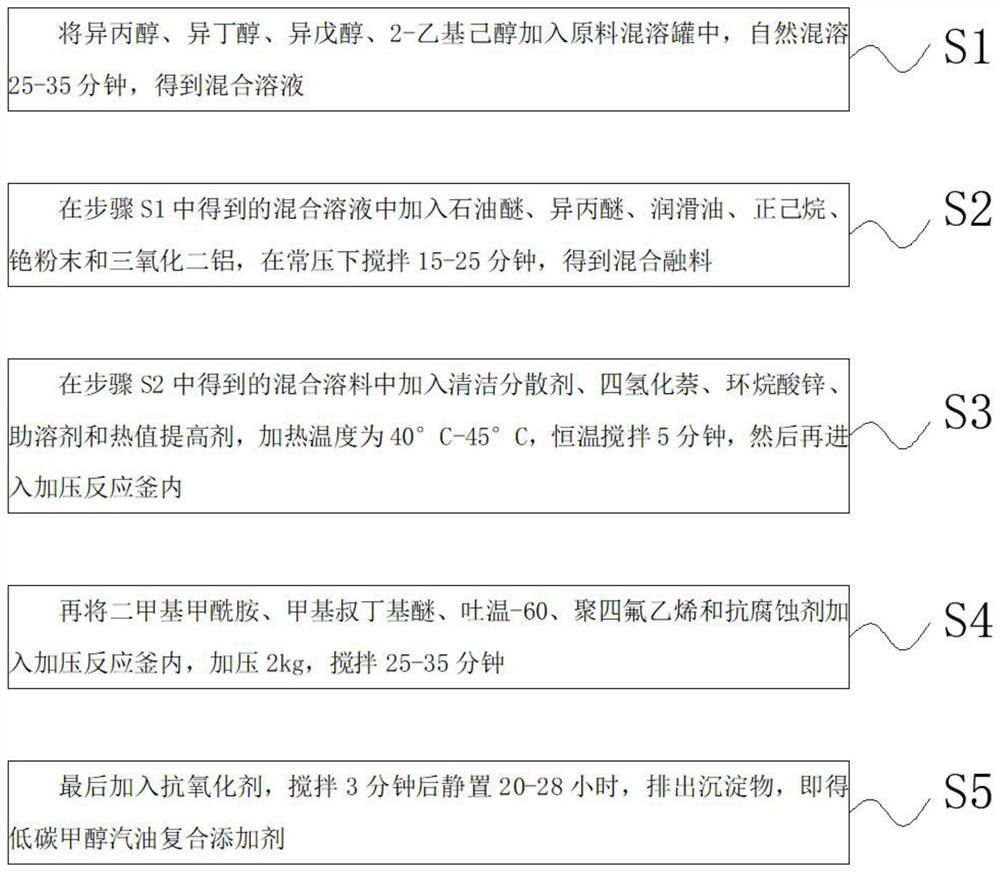

[0025] see figure 1 , the present invention provides a technical solution:

[0026] A low-carbon methanol-gasoline composite additive prepared from the following raw materials in parts by weight: lubricating oil: 5 parts, n-hexane: 0.5 parts, cesium powder: 0.2 parts, aluminum oxide: 3 parts, cosolvent: 1 part, calorific value enhancer: 2 parts, corrosion inhibitor: 0.5 parts, antioxidant: 0.5 parts, isopropanol: 30 parts, isobutanol: 15 parts, isoamyl alcohol: 15 parts, 2-ethylhexanol : 3 parts, detergent and dispersant: 0.5 parts, petroleum ether: 0.2 parts, isopropyl ether: 0.2 parts, tetralin: 0.2 parts, zinc naphthenate: 0.8 parts, dimethylformamide: 0.8 parts, methyl tert-butyl ether: 0.2 parts and polytetrafluoroethylene: 0.8 parts.

[0027] see figure 1 , the detergent and dispersant is barium petroleum sulfonate or succinimide;

[0028] see figure 1 , the co-solvent is: any one or two of acetone, methyl ethyl ketone, n-butanol, isopropanol;

[0029] see figure ...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution:

[0040] A low-carbon methanol-gasoline composite additive prepared from the following raw materials in parts by weight: lubricating oil: 10 parts, n-hexane: 0.8 parts, cesium powder: 0.5 parts, aluminum oxide: 5 parts, cosolvent: 5 parts, calorific value enhancer: 3 parts, corrosion inhibitor: 2 parts, antioxidant: 1 part, isopropanol: 40 parts, isobutanol: 20 parts, isoamyl alcohol: 25 parts, 2-ethylhexanol : 6 parts, detergent and dispersant: 1.5 parts, petroleum ether: 10 parts, isopropyl ether: 5 parts, tetralin: 1.2 parts, zinc naphthenate: 1.2 parts, dimethylformamide: 1.2 parts, methyl tert-butyl ether: 15 parts and polytetrafluoroethylene: 1.2 parts.

[0041] see figure 1 , the detergent and dispersant is barium petroleum sulfonate or succinimide;

[0042] see figure 1 , the co-solvent is: any one or two of acetone, methyl ethyl ketone, n-butanol, isopropanol;

[0043] see figure 1 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com