Array substrate and display device

An array substrate and array substrate row technology are applied in the fields of array substrates and display devices, which can solve the problems of metal corrosion of display devices, and achieve the effects of avoiding metal corrosion problems and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] As mentioned in the background, the existing display devices using the GOA technology have metal corrosion problems. The inventors of the present invention have found after research that one of the reasons for the aforementioned problems is:

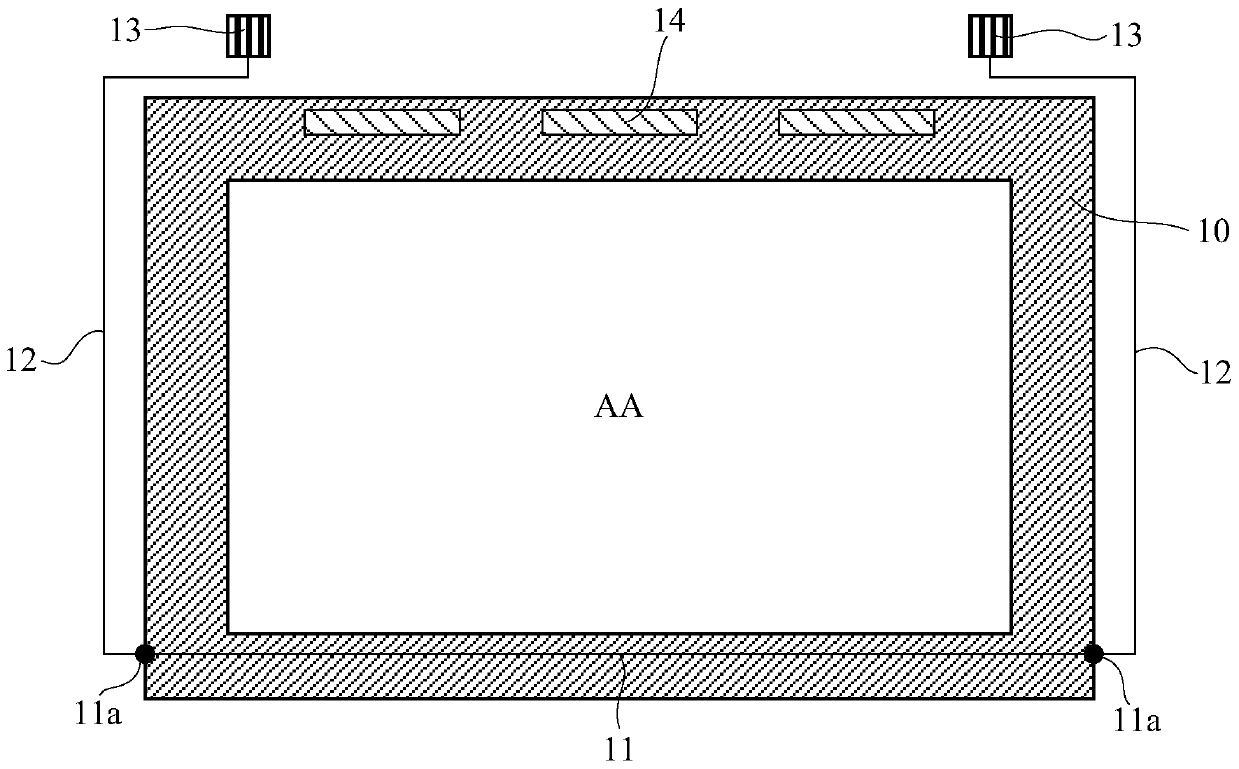

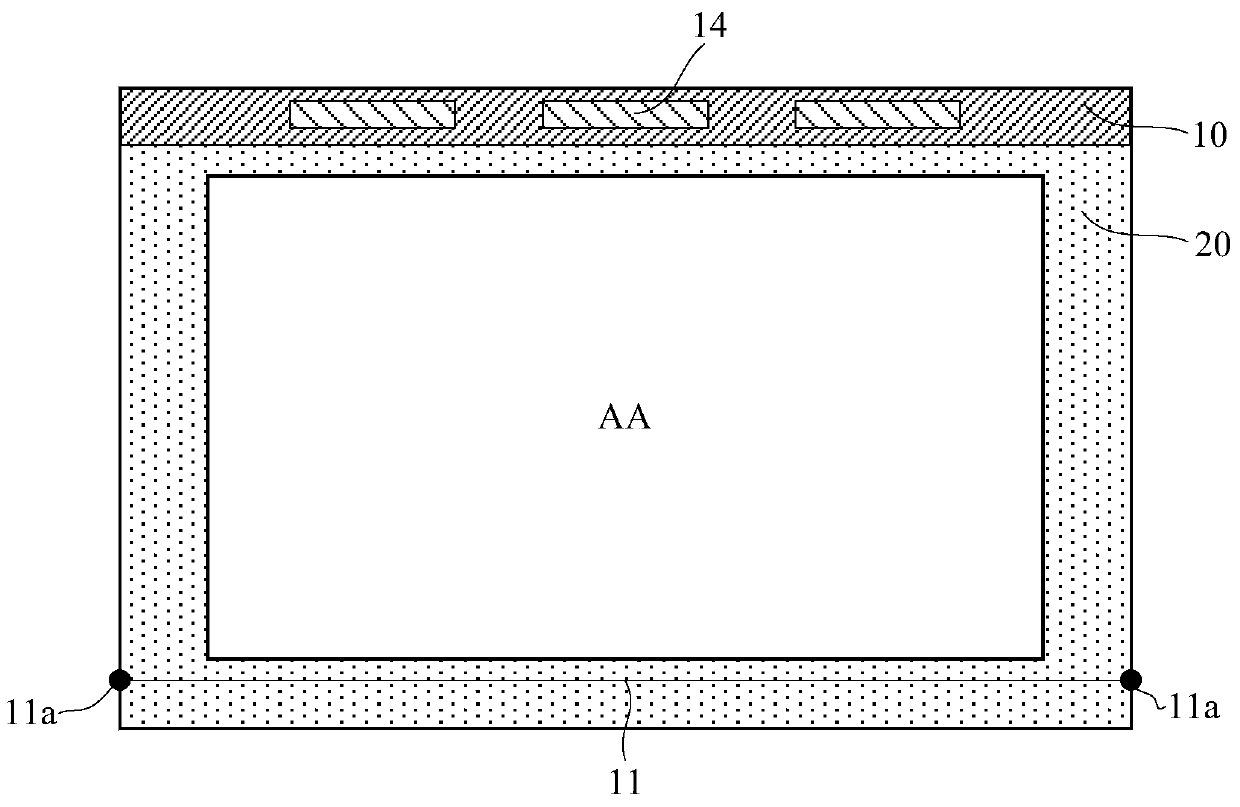

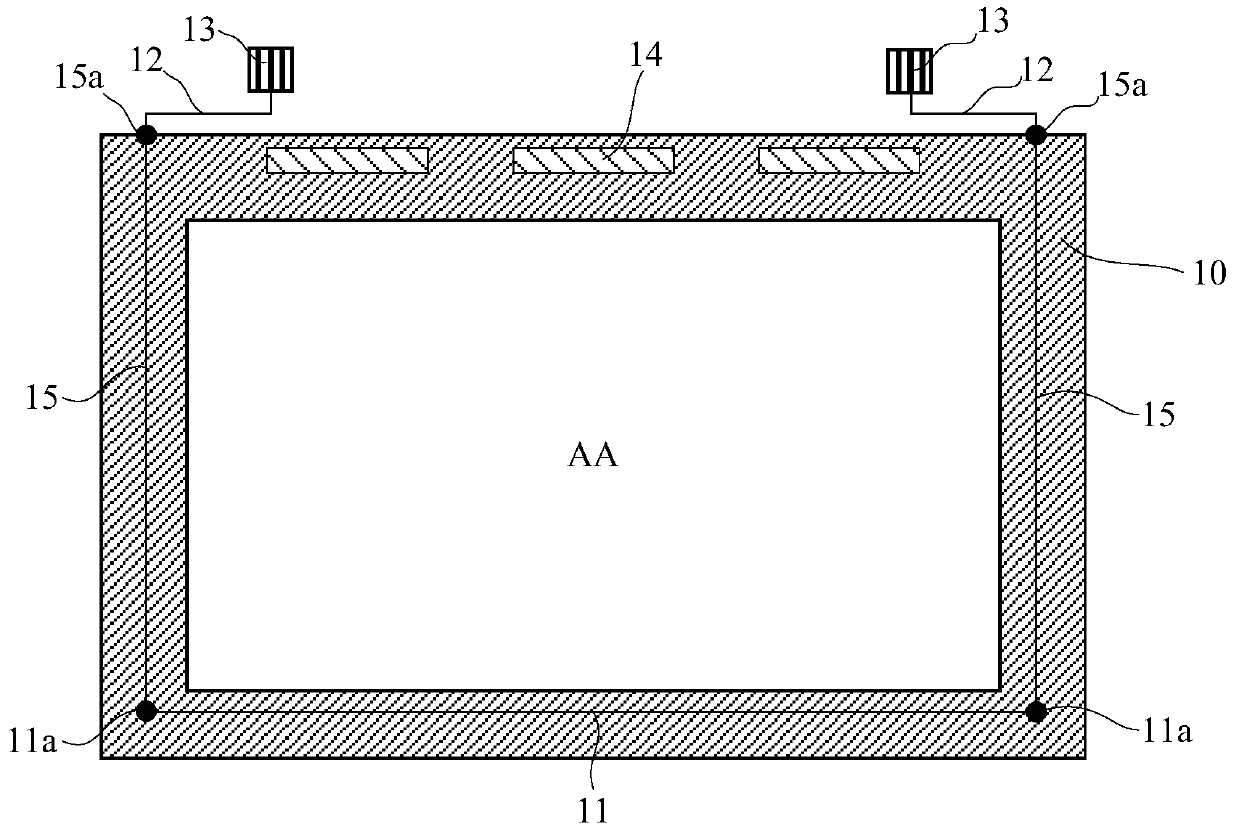

[0032] Such as figure 1 As shown, the array substrate 10 has a display area AA, GOA units (not shown) are arranged on the left and right sides outside the display area AA, and a data binding pad 14 is arranged on the outside of the display area AA, which is called a data binding pad. The side where 14 is located is the DP side of the array substrate 10 , the side opposite to the DP side is the DPO side of the array substrate 10 , and the two sides where the GOA unit is located are the GOA sides of the array substrate 10 .

[0033] In order to ensure product yield, in the final stage of the array substrate 10 manufacturing process, it is necessary to inspect the gate lines, data lines and other signal lines on the array substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com