Protective and rustproof packaging material for condensation-proof steel coil and production method thereof

A technology for anti-rust packaging materials and production methods, applied in the directions of packaging, wrapping paper, transportation and packaging, etc., can solve the problems of incomplete airtightness, affecting the anti-rust function of products, and single function, and achieve the effect of increasing protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

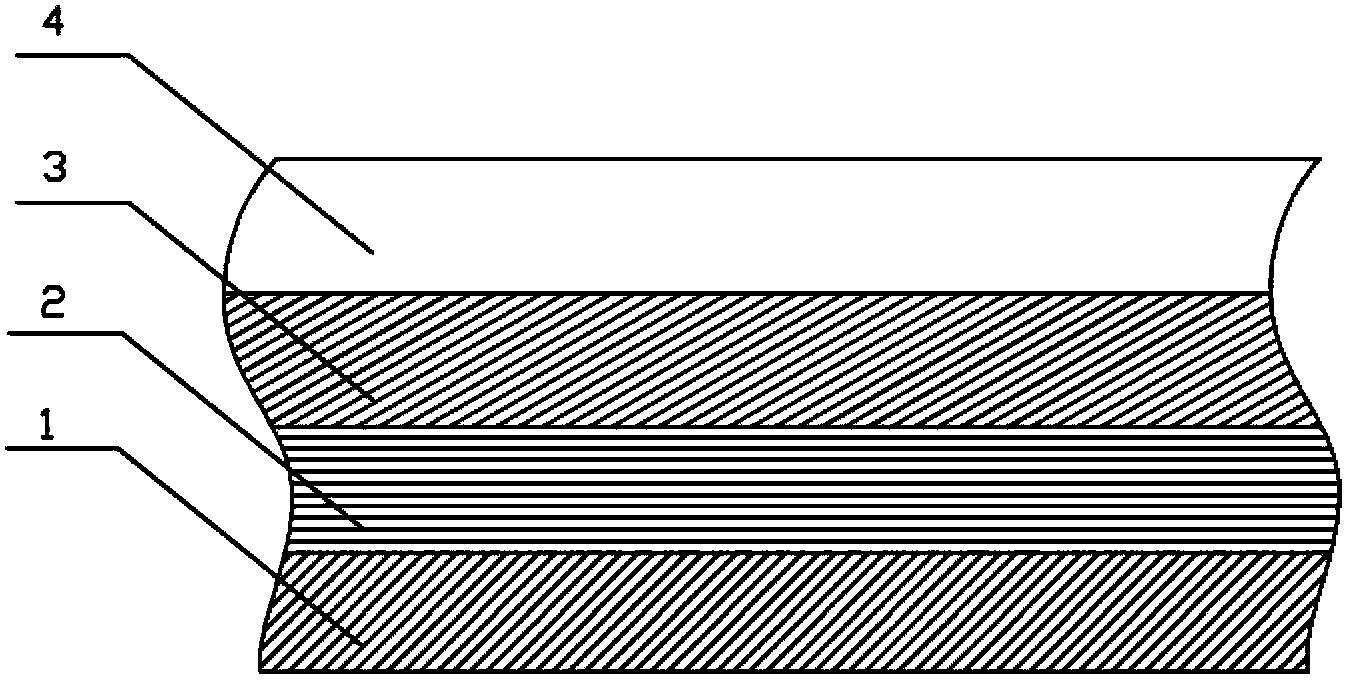

Image

Examples

Embodiment 1

[0022] The production method of protection and antirust packaging material for anti-condensation steel coil of the present invention is as follows:

[0023] 1. Polyolefin layer: It is made by mixing low-density polyethylene (LDPE) and gas phase corrosion inhibitor. The mass percent content of the LDPE component is 98%, and the mass percent content of the vapor phase corrosion inhibitor component is 2%.

[0024] In this embodiment, the gas phase corrosion inhibitor is benzotriazole.

[0025] 2. Production of wood pulp spunlace non-woven fabric layer: After mixing wood pulp fiber and polyester fiber, it is produced by continuous one-step process of high temperature melting, spinning, laying, and hot pressing. The polyester fiber component in the raw material The mass percentage is 80%, and the mass percentage of the wood pulp fiber component is 20%.

[0026] 3. Production of polyolefin woven fabric layer: It is made of matrix resin high-density polyethylene (HDPE) and anti-agi...

Embodiment 2

[0030] The production method of protection and antirust packaging material for anti-condensation steel coil of the present invention is as follows:

[0031] 1. Polyolefin layer: It is made by mixing EVA and gas phase corrosion inhibitor. The mass percent content of the EVA component is 95%, and the mass percent content of the vapor phase corrosion inhibitor component is 5%.

[0032] The vapor phase corrosion inhibitors in this example are benzotriazole derivatives (2%) and benzoate (3%).

[0033] 2. Production of wood pulp spunlace non-woven fabric layer: After mixing wood pulp fiber and polypropylene fiber, it is produced by continuous one-step process of high-temperature melting, spinning, laying, and hot-pressing. The polypropylene fiber component in the raw material The mass percentage is 90%, and the mass percentage of the wood pulp fiber component is 10%.

[0034] 3. Production of polyolefin woven fabric layer: It is made of matrix resin high-density polyethylene (HDPE...

Embodiment 3

[0038] The production method of protection and antirust packaging material for anti-condensation steel coil of the present invention is as follows:

[0039] 1. Polyolefin layer: It is made by mixing PP and gas phase corrosion inhibitor. The mass percent content of the PP component is 92%, and the mass percent content of the vapor phase corrosion inhibitor component is 8%.

[0040] The vapor phase corrosion inhibitors in this example are imidazole (5%) and sodium nitrite (3%).

[0041] 2. Production of wood pulp spunlace non-woven fabric layer: After mixing wood pulp fiber and polypropylene fiber, it is produced by continuous one-step process of high-temperature melting, spinning, laying, and hot-pressing. The polypropylene fiber component in the raw material The mass percentage is 70%, and the mass percentage of the wood pulp fiber component is 30%.

[0042]3. Production of polyolefin woven fabric layer: It is made of matrix resin high-density polyethylene (HDPE) and anti-ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com