Flexible bogies for rail vehicles

A rail vehicle and bogie technology, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, can solve problems such as short service life, poor reliability, and large wheelbase wheelbase, so as to reduce production costs and improve The effect of obedience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

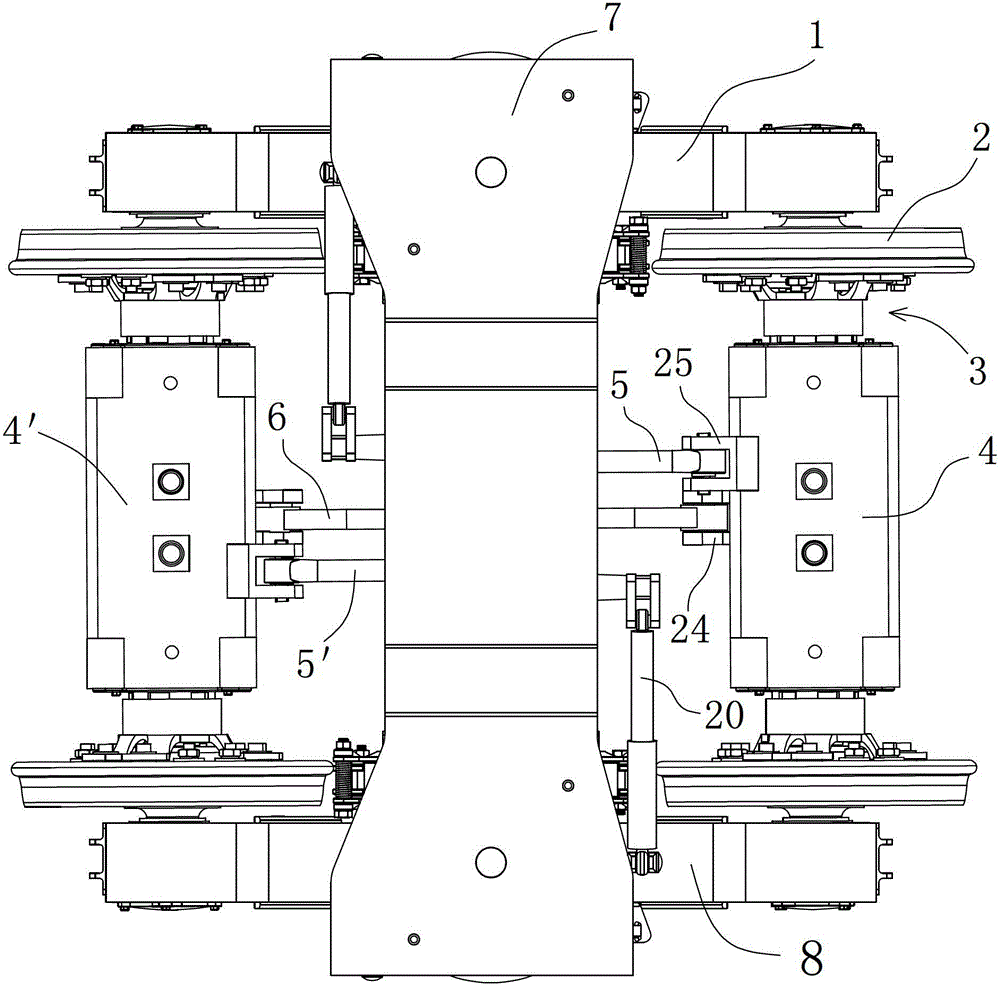

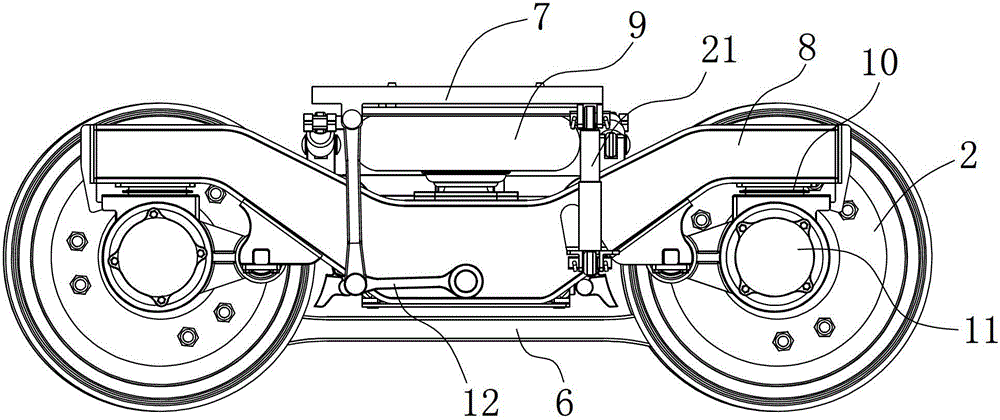

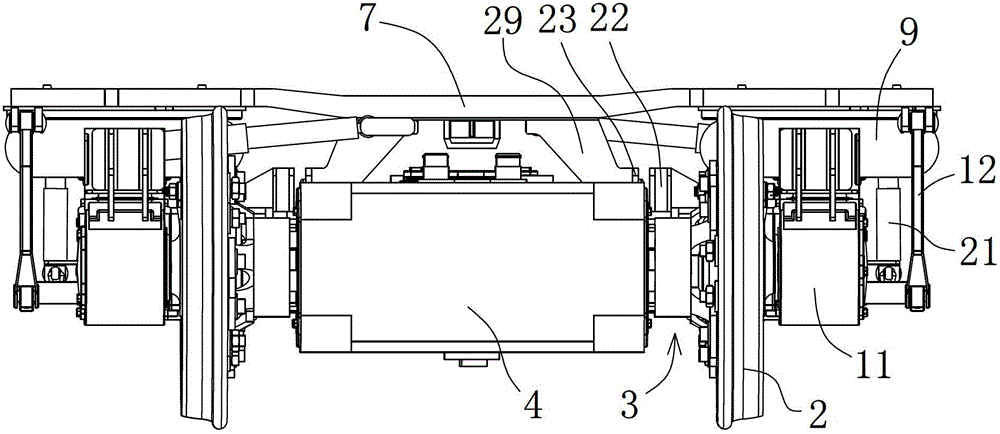

[0027] Such as Figure 1 to Figure 10 As shown, the rail vehicle flexible bogie of this embodiment consists of: a bogie frame, two permanent magnet motors 4 (4') located at the front and rear sides of the bogie frame, and an air spring 9 arranged above the bogie frame 1. The front and rear wheel sets arranged under the bogie frame. The bogie frame has a left frame 1 and a right frame 8. The middle part of the left frame 1 and the middle part of the right frame 8 are fixedly connected by a flexible beam 13 composed of four steel plates. As a whole, there are gaps between the four steel plates. Due to the flexible frame, the primary suspension of this embodiment is simplified, and the specific structure is as follows: the left side frame 1 and the right side frame 8 are respectively equipped with a series of elastic cushions, and a series of elastic cushions are arranged between the axle box 11. There is a rubber pad 10 as a series of suspensions, and the rubber pad 10 is a sin...

Embodiment 2

[0036] The structure of the second embodiment is the same as that of the first embodiment, the difference lies in the different parameters of the flexible beam. The frame wheelbase is 1800mm, and the steel plate material is P275. The analysis shows that the torsional stiffness of the frame is 0.315MN.m / rad, and the shear stiffness is 102.98MN.m / rad. Guarantees higher serpentine stability of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com