Flexible joint analog device with adjustable gaps of space manipulator

A space manipulator and flexible joint technology, applied in the aerospace field, can solve the problems of high cost, difficult to achieve flexible large load, and long simulation test verification period with adjustable joint gap, so as to save experimental investment and shorten verification period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

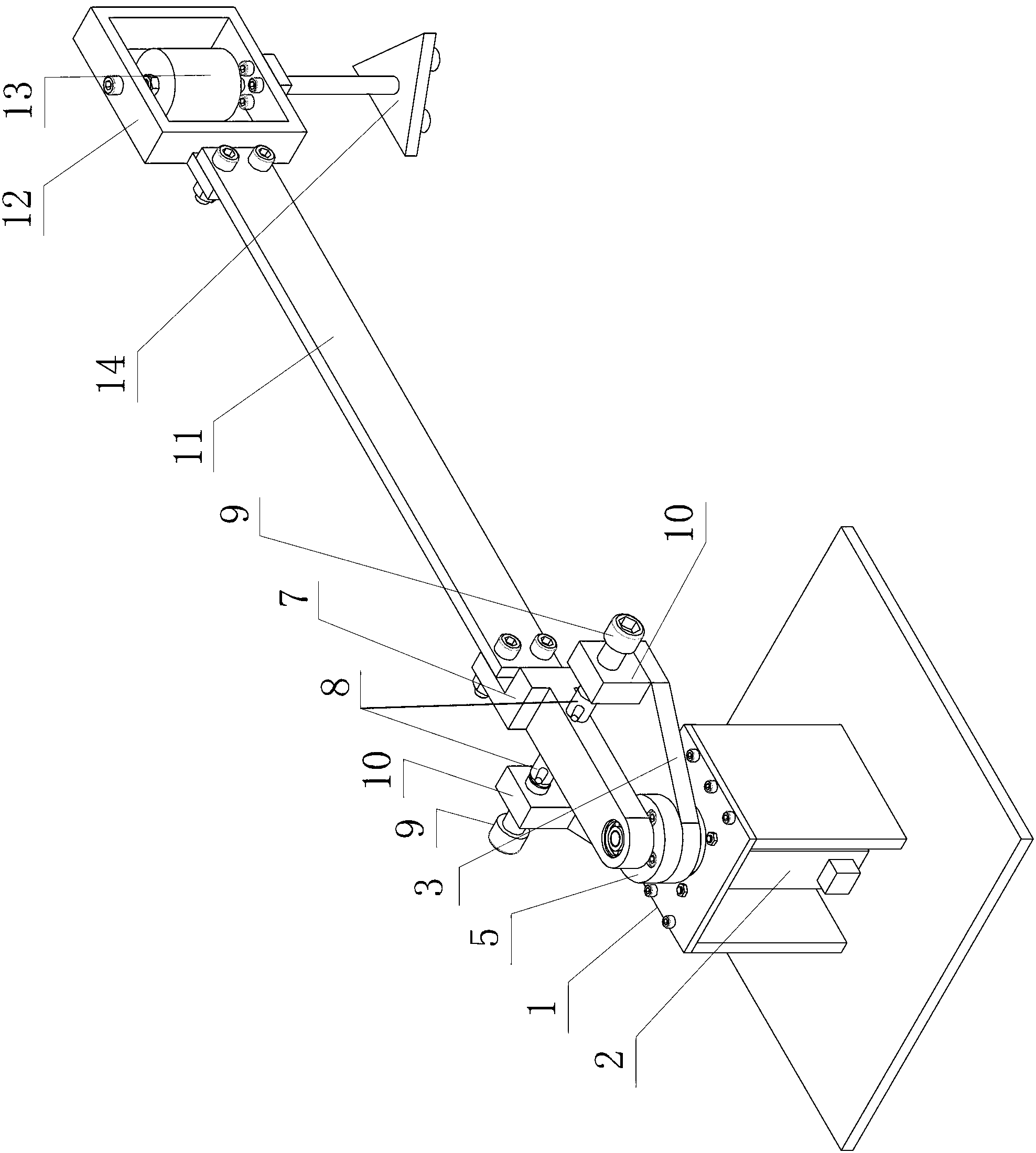

[0012] Specific implementation mode one: as figure 1 As shown, the flexible joint simulation device with adjustable space manipulator gap in this embodiment includes a motor fixing base 1, a driving motor 2, a gap adjustment turntable 3, a disc-shaped extension shaft 5, a driving connecting rod 7, a flexible elastic piece 11, a load fixing Frame 12, weight 13, air-floating feet 14, two force sensors 8, two gap-adjusting hexagon socket screws 9, two screw fixing seats 10; the driving motor 2 is fixed on the test bench through the motor fixing seat 1, and the driving The output shaft of the motor 2 is vertically arranged upwards, the output shaft of the gap adjustment turntable 3 is affixed to the drive motor 2, the disc extension shaft 5 is fixed on the upper end surface of the gap adjustment turntable 3 and the disc extension shaft 5 is connected to the drive motor The output shafts of 2 are coaxially arranged, one end of the drive connecting rod 7 is rotationally connected wi...

specific Embodiment approach 2

[0016] Specific implementation mode two: as figure 1 As shown, one end of the driving connecting rod 7 in this embodiment is rotatably connected to the upper part of the disc-shaped extension shaft 5 through two deep groove ball bearings, and the two deep groove ball bearings are respectively sleeved on the disc-shaped extension shaft 5 up and down. With such arrangement, the inner ring of the bearing is closely matched with the disc-shaped extension shaft 5, and the outer ring of the bearing is closely matched with the driving connecting rod 7, so that the rolling and sliding effect is good. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: as figure 1 As shown, the disk-shaped extension shaft 5 in this embodiment is composed of a fixed disk 5-1 and an extension shaft 5-2, and the extension shaft 5-2 and the fixed disk 5-1 are coaxially fixed as a whole. Designed in this way, it is convenient for the disc-shaped extension shaft 5 to be fixed on the clearance adjustment rotary disk 3 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com