Lithium battery current collector with temperature sensing function and preparation method thereof

A lithium battery and current collector technology is applied in the field of lithium battery current collector with temperature sensing function and its preparation, and can solve the problem of reducing the capacity charging and discharging efficiency of lithium ion battery, reducing the reliability of temperature sensor monitoring, and insufficient adhesion at the interface. and other problems to achieve the effect of reducing the difficulty of preparation, improving adhesion, and ensuring reliability and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

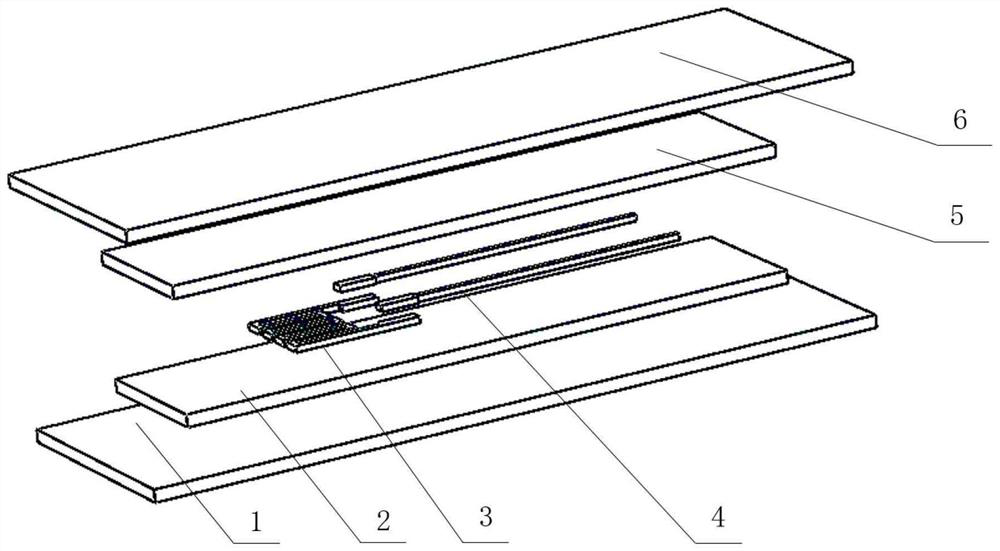

[0032] A preparation method of a lithium battery current collector with a temperature sensing function, comprising the following steps:

[0033] Step 1. Perform ultrasonic cleaning on the metal foil with acetone, alcohol and deionized water to remove impurities on the surface of the metal foil; use plasma cleaning on the area where the flexible insulating layer (2) is preset on the metal foil (1) machine to perform plasma cleaning, improve the roughness of the pre-arranged flexible insulating layer area, and enhance the adhesion of the flexible insulating layer (2) on the surface of the metal foil (1). The positive metal foil is aluminum foil with a thickness of 20 μm; the negative metal The foil is copper foil with a thickness of 5-15 μm;

[0034] Step 2. The area surface of the flexible insulating layer (2) is pre-set on the metal foil (1), and the polyimide solution is coated by the coating process, and the coated metal foil (1) is placed in a 70°C In the oven for 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com