Flexible electronic pressure sensor and preparation method thereof

A pressure sensor, flexible technology, applied in the direction of sensors, respiratory organs, medical science, etc., can solve the problems of low sensitivity and limited detection ability of flexible tactile sensors, and achieve strong pressure sensitivity, good sensing performance, and outstanding elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

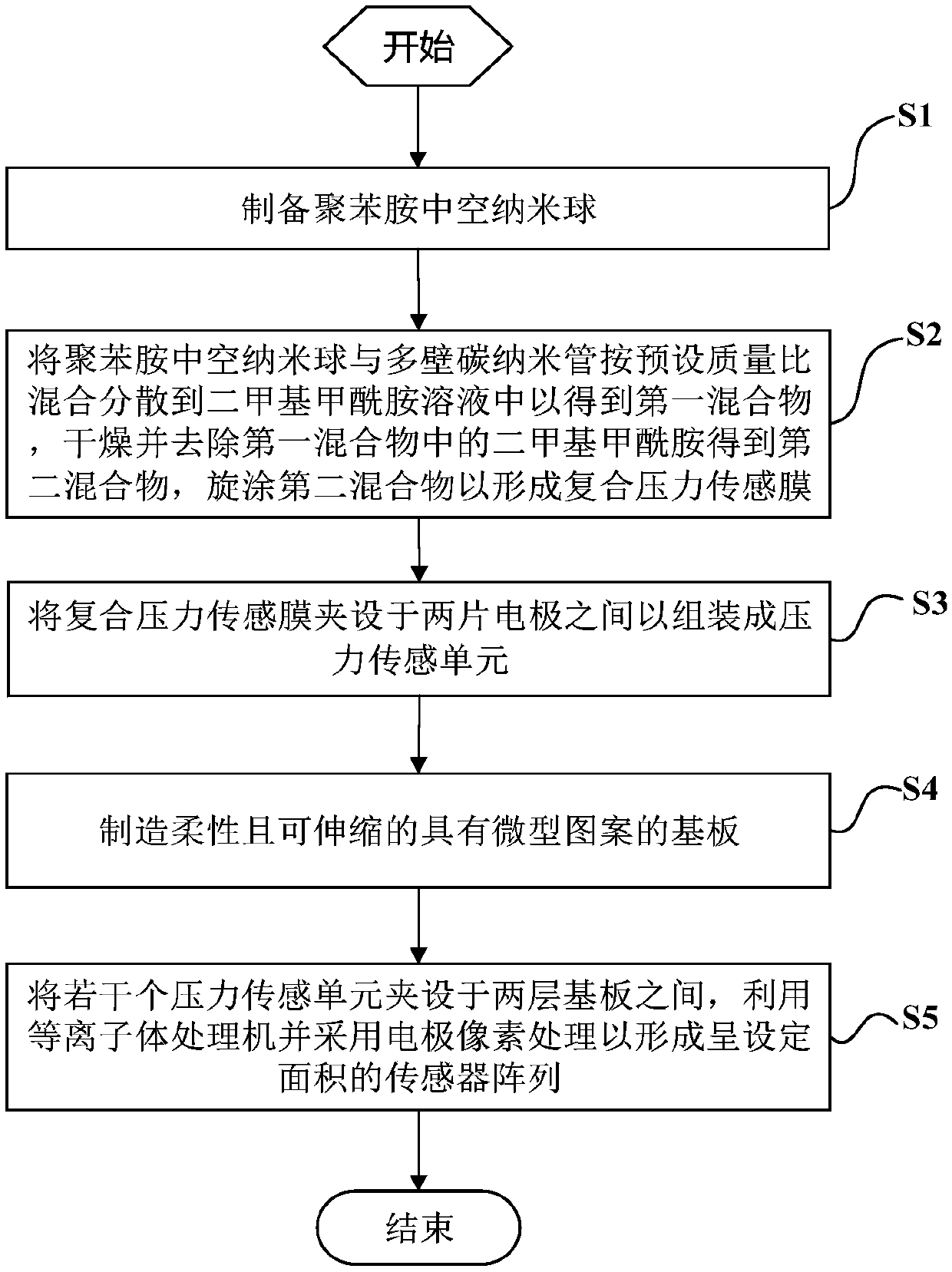

[0037] figure 2 The method flowchart of an example provided for the preparation method of the flexible electronic pressure sensor of the present invention, as figure 2 Shown, the preparation method of flexible electronic pressure sensor comprises the following steps:

[0038] Step S1, preparing polyaniline hollow nanospheres 31;

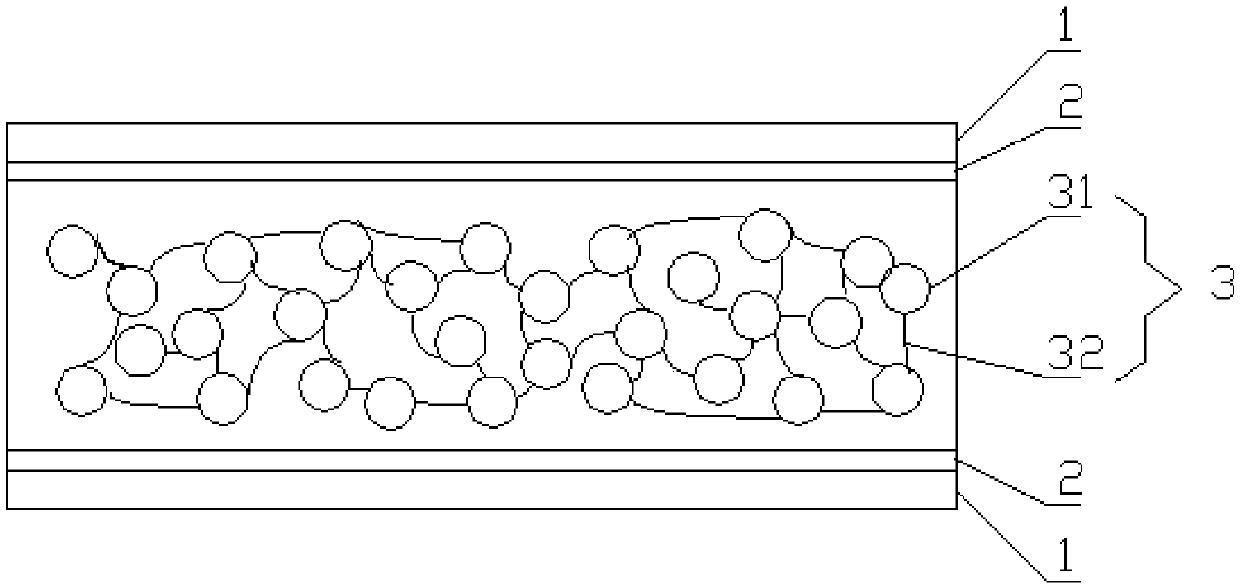

[0039] Step S2, mixing and dispersing polyaniline hollow nanospheres 31 and multi-walled carbon nanotubes 32 in a preset mass ratio into a dimethylformamide solution to obtain a first mixture, drying and removing the first mixture in step S2 The dimethylformamide in obtains the second mixture, spin coats the second mixture to form the composite pressure sensing membrane 3;

[0040] Step S3, sandwiching the composite pressure sensing film 3 between the two electrodes 2 to assemble a pressure sensing unit;

[0041] Step S4, manufacturing a flexible and stretchable substrate 1 with micro-patterns;

[0042]In step S5, a plurality of pressure sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com