Conveniently cleaned powder supplying device

A powder supply device and a convenient technology, applied in transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of inconvenience, poor cleaning effect, and inability to realize automatic cleaning, etc., to achieve convenient and fast cleaning and good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

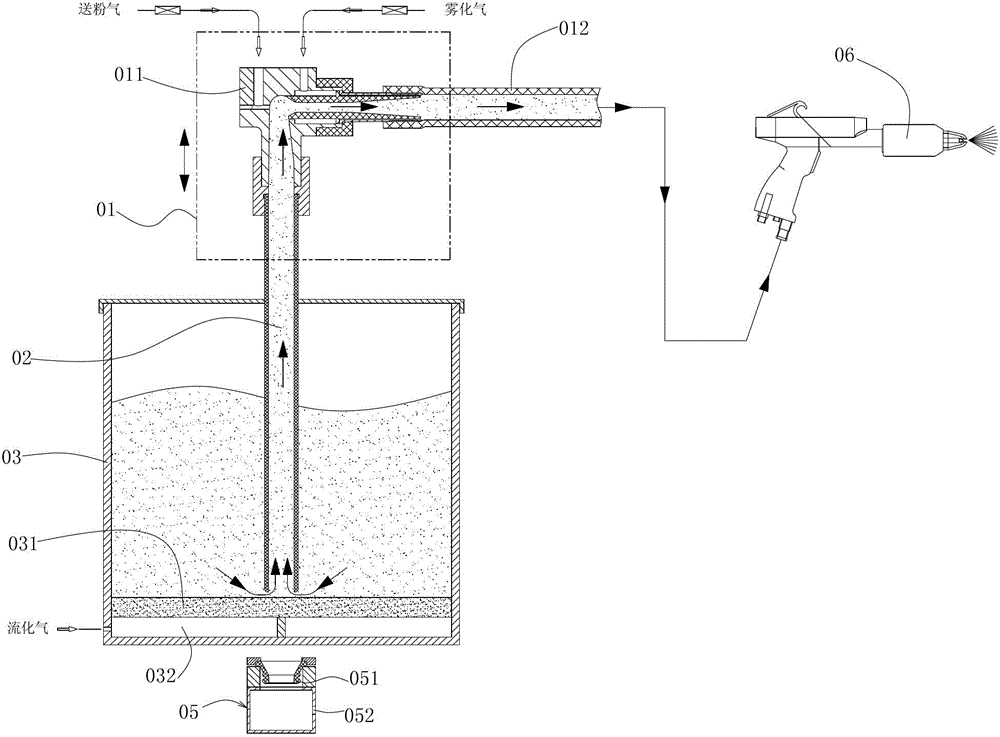

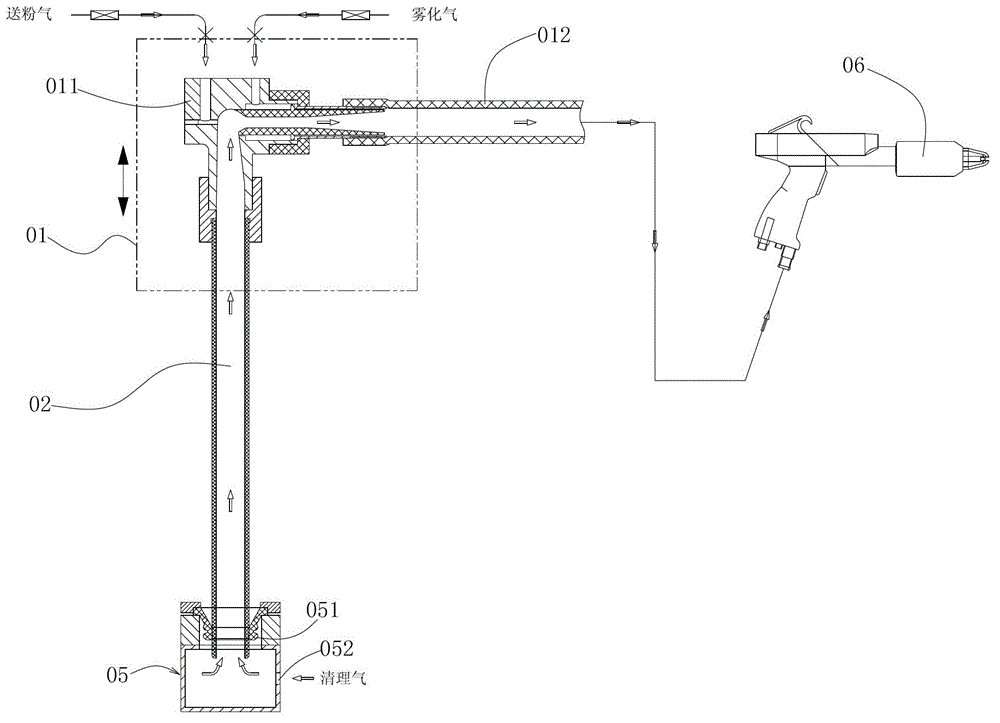

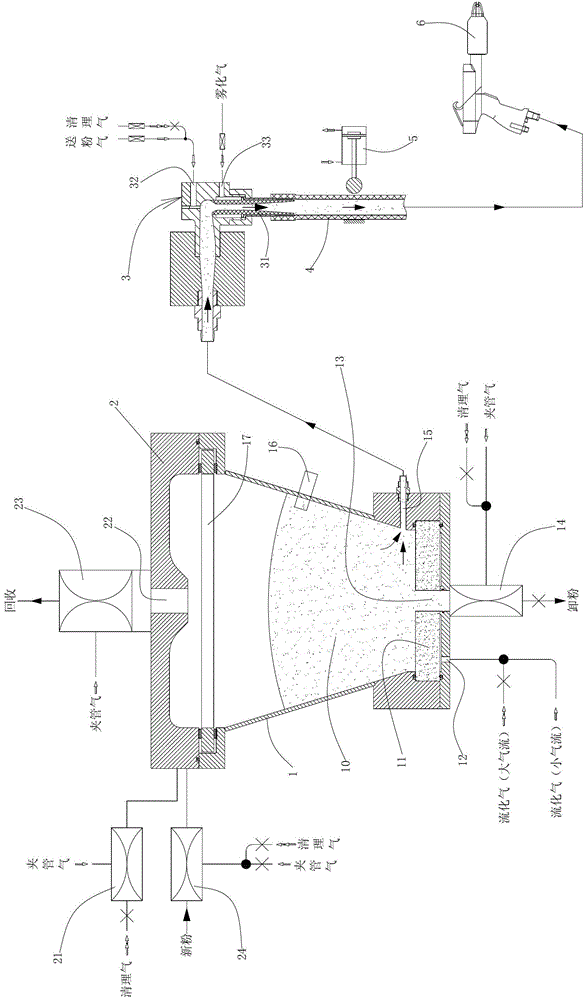

[0034] As shown in the figure, a powder supply device that is easy to clean includes a powder hopper 1, a powder hopper cover 2, a fluidized plate 11, a powder suction pump 3, a powder delivery pipeline 4, a pipeline opening and closing control mechanism 5, and a spray gun 6.

[0035] The upper end of the powder hopper 1 is open and the bottom end is closed, and has a cavity for containing powder 10. The bottom of the powder hopper 1 is provided with a fluidized gas inlet 12, and the bottom of the powder hopper 1 is also provided with a powder discharge port 13. The powder port 13 is connected with an external powder unloading contraction valve 14 .

[0036] The powder hopper cover 2 is sealed and matched with the upper opening of the powder hopper 1. A cleaning air inlet (not shown in the figure) connected with the powder hopper cavity is provided on the powder hopper cover 2. The cleaning air inlet is connected with an outer Set cleaning shrink valve 21 connection. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com