Electrical rotary opening-closing hanger for amplitude-change vehicle mould

A technology for electric rotation and automobile molds, applied in the field of spreaders, can solve the problems of large area of mold stacking, dangerous personnel operations, low production efficiency, etc., and achieve the effect of improving corporate image, improving production efficiency, and reducing site construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

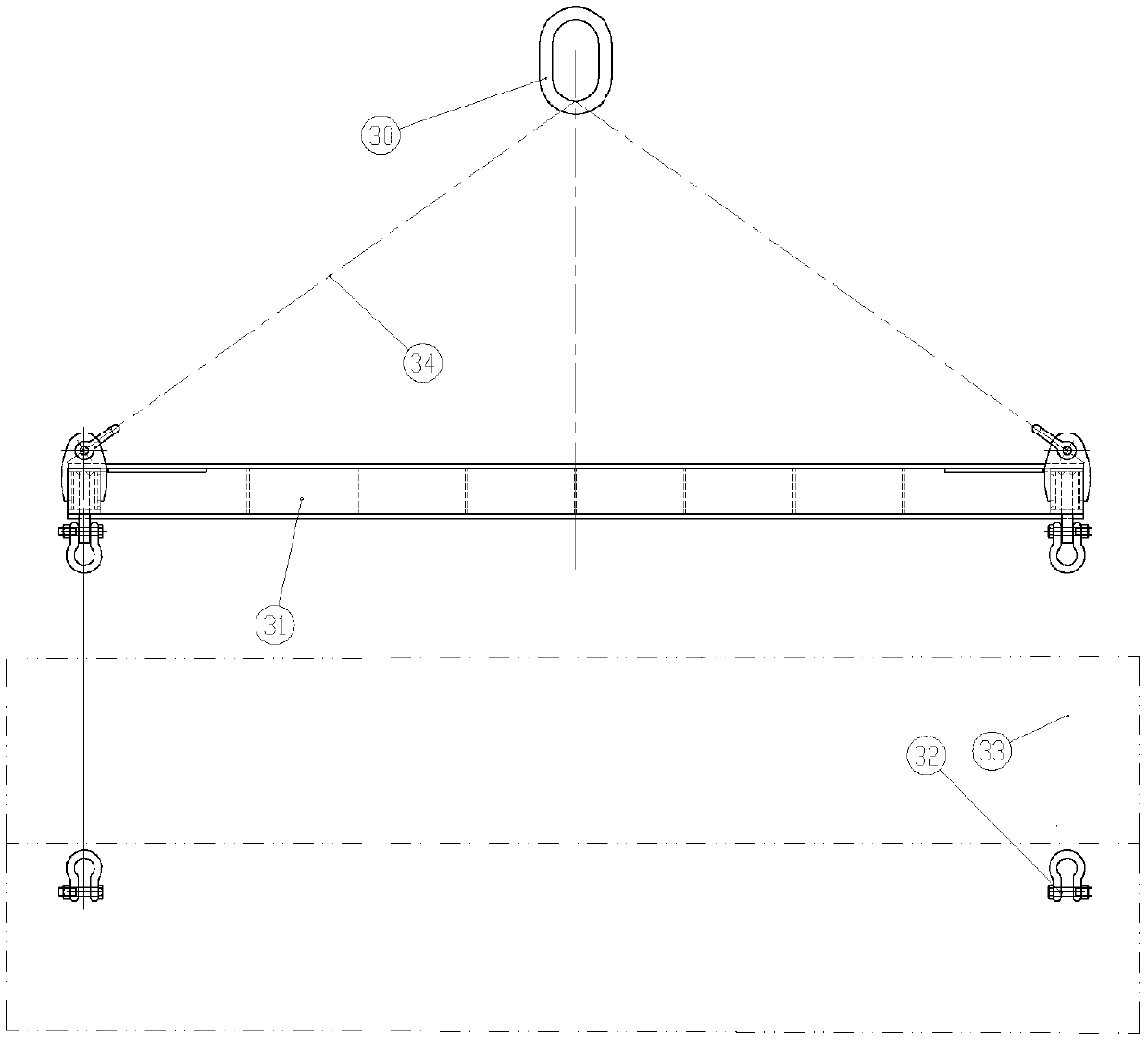

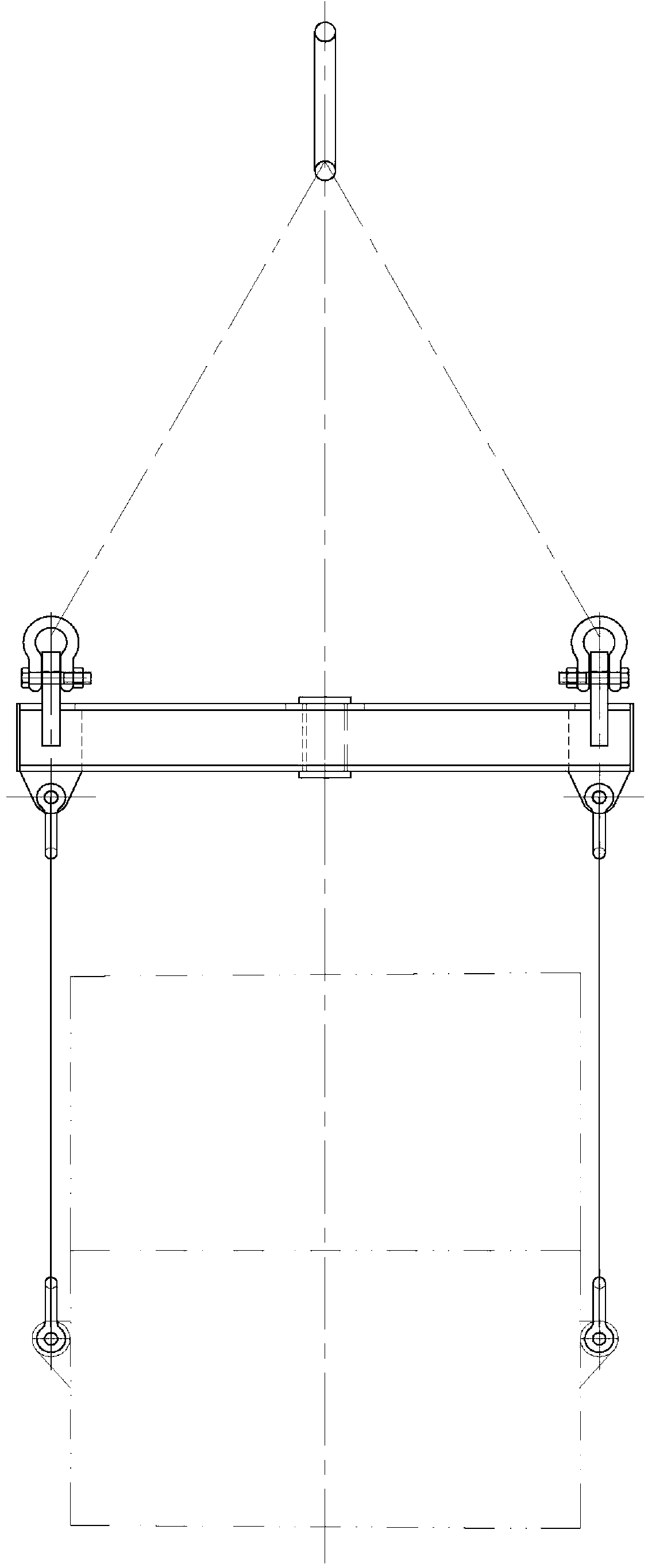

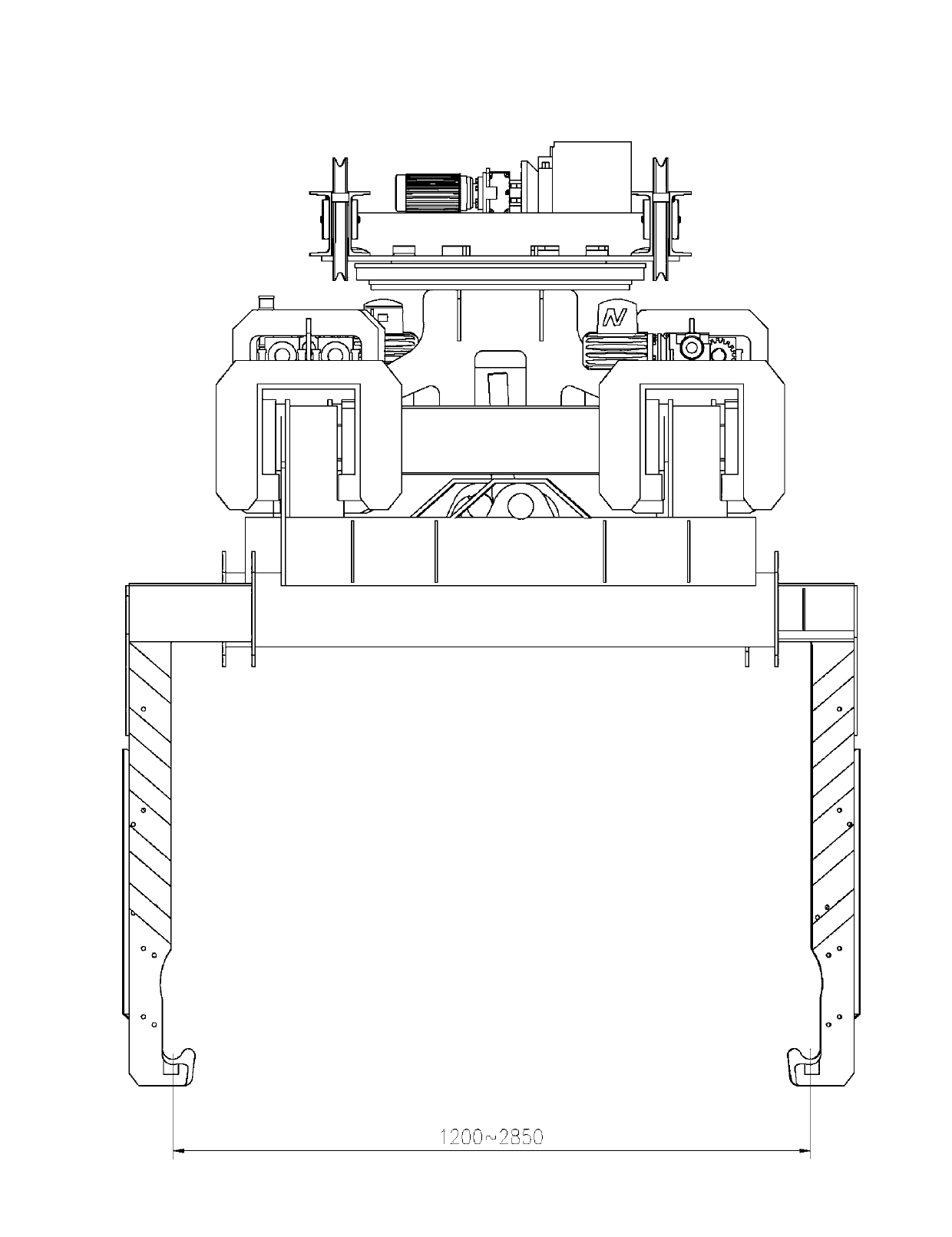

[0025] A 40t electric rotary opening and closing luffing car mould spreader, such as image 3 , Figure 4 with Image 6 As shown, its composition includes: pulley block 1, upper beam 2, rotating three-in-one deceleration brake motor 3, slewing support 4, luffing three-in-one deceleration brake motor 5, luffing screw 6, luffing nut 7, Lower beam 8, maintenance ingot hook 9, welding hook 10, luffing beam 11, opening and closing box body 12, clamp arm 13, opening and closing screw 14, opening and closing nut 15, clamp shoe 16, indicator light and electric control System 17, luffing box 18, opening and closing three and one deceleration brake motor 19, four sets of pulleys 1 are installed at the four corners of the upper cross beam 2, which are connected with a crane by wire ropes, and the spreader is equipped with various sensors, indicator lights, For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com