Three-grid type septic tank assembled by four modules

A technology of septic tanks and anaerobic tanks, which is applied in the field of three-format septic tanks assembled by four modules, can solve the problems of ineffective treatment, long construction period, and short service life, so as to facilitate production organization, reduce transportation costs, The effect of physical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

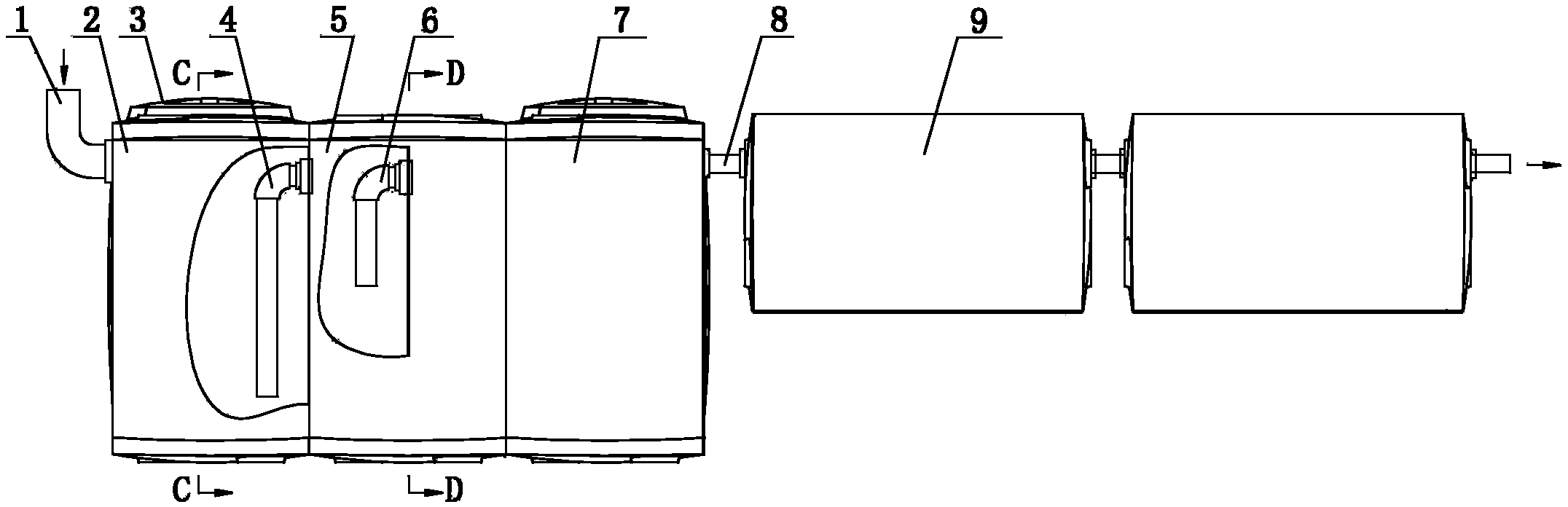

[0023] Such as figure 1 Shown, a kind of four module assembles three format septic tanks, comprises sedimentation fermentation tank 2, anaerobic tank 5 and storage tank 7, is equipped with liquid inlet pipe 1 in sedimentation fermentation tank 2, in sedimentation fermentation tank 2 and anaerobic A first-level communication pipe 4 is installed between the pools 5, and the opening of the first-level communication pipe 4 in the sedimentation fermentation tank 2 is lower than the opening in the anaerobic tank 5; The opening of the pipe 6 and the secondary connecting pipe 6 in the anaerobic tank 5 is lower than the opening in the liquid storage tank 7;

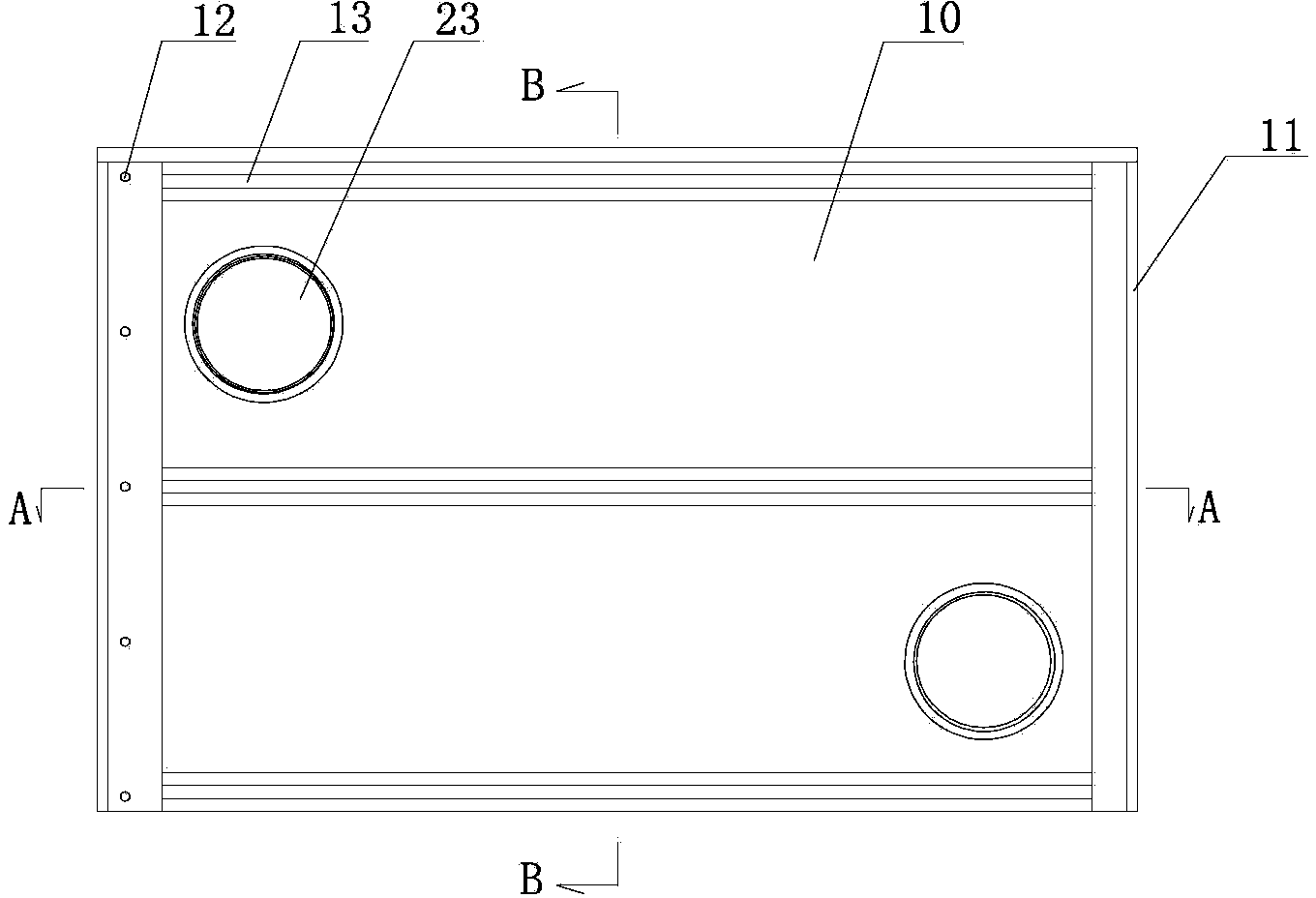

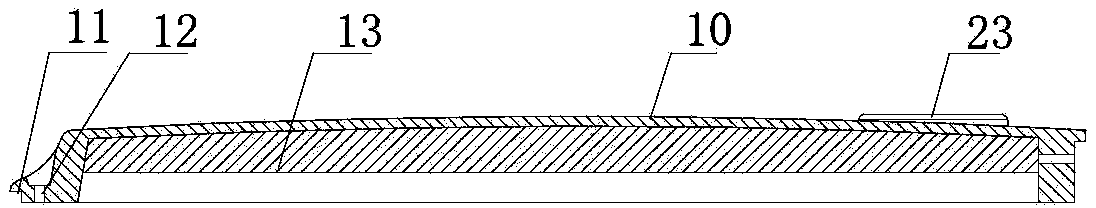

[0024] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, the described sedimentation fermentation tank 2, the anaerobic tank 5 and the liquid storage tank 7 are assembled by modules, and the modules include: a side wall 10, a top wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com