Patents

Literature

39results about How to "Improve physical and chemical performance indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing biomass fuel by animal and vegetable oil leftover catalytic cracking

InactiveCN101328420AReduce environmental pollutionThe equipment is less corrosiveBiofuelsLiquid hydrocarbon mixture productionScrapMolecular sieve

The invention discloses a method for producing biomass fuel by catalytic cracking from scraps of animal and vegetable oil. The method comprises the following steps that: the animal and vegetable oil or the scraps thereof are subjected to decontamination and dehydration to make an impurity content less than 3 percent and a moisture content less than 3 percent; 2. under the condition of normal temperature, a mass ratio between a raw material and a catalyst in a reaction kettle is between 100 to 2 and 10, the reaction kettle is slowly heated to a temperature of between 300 and 500 DEG C to carry out a catalytic cracking reaction; and a product obtained after the reaction is distilled under normal pressure, a biological gasoline fraction is distilled at a temperature of between 40 and 190 DEG C, and a biological diesel fraction is distilled at a temperature of between 190 and 290 DEG C; and 4. the catalyst is amorphous aluminum silicate, gamma-Al2O3 or a molecular sieve. Compared with the prior method for producing biodiesel by an esterification method or an interchange esterification method, the method for producing the biomass fuel of the invention does not use concentrated sulfuric acid or inorganic base which have strong corrosiveness, has small pollution to the environment and small corrosion to equipment, and reduces cost in sewage treatment; and the raw material has wide application range, comprising animal and vegetable fat, hogwash oil, waste oil, chafing dish oil, bottom oil of plant oil, soapstock, acidified oil and so on, has no restriction on the acid value of the raw material.

Owner:CHONGQING HUAZHENG ENERGY SOURCE DEV

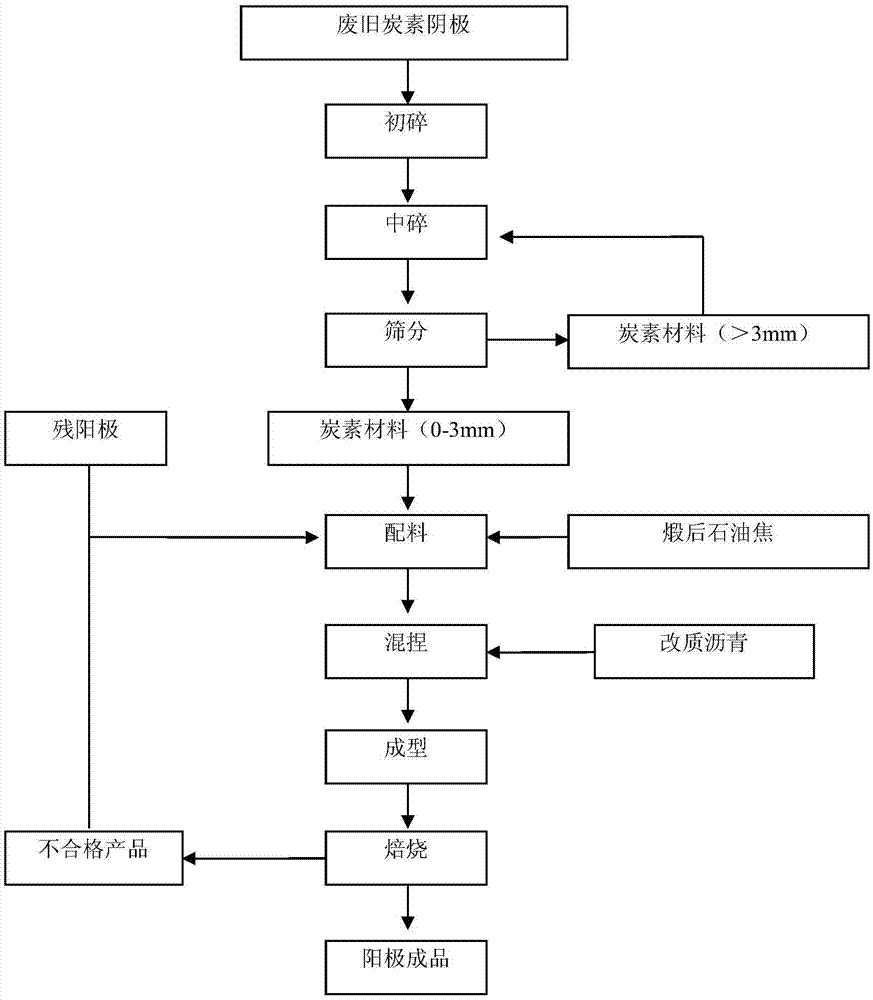

Method for preparing prebaked anode by using aluminum electrolysis waste carbon cathode

The invention discloses a method for preparing a prebaked anode by using an aluminum electrolysis waste carbon cathode. A lining carbon material of the aluminum electrolysis waste carbon cathode is separated out and roughly smashed; the roughly smashed carbon material with a particle size smaller than 70 mm is intermediately smashed to separate out a particle material with a particle size not bigger than 3 mm; an aluminum-electrolyzed residual anode or a waste anode roasted by an anode production line is roughly smashed to obtain a rough residue; the roughly smashed rough residue with a particle size smaller than 70 mm is intermediately smashed to separate out a fine residue with a particle size not bigger than 3 mm; rough coke, medium coke and fine coke of calcined petroleum coke, powder, primary residue, fine residue and a carbon material are mixed, are preheated to fed a kneading machine, and are added in liquid asphalt for kneading; kneaded paste is strongly cooled to feed a forming machine to obtain a formed carbon block for cooling; and finally, the formed carbon block is roasted and heated until the asphalt is converted to a coke to form a firm and uniform whole. The method can perform the harmless treatment and the resource recycling for the waste carbon cathode, and is simple in preparation process.

Owner:YUNNAN RUNXIN ALUMINUM +1

Preparation method of anti-lighting and resistance-reducing grounding module material

InactiveCN106967438AStable structureExtended service lifeOrganic fertilisersConnection contact member materialDry mixingComputer module

The invention belongs to the technical field of carbon materials and particularly relates to a preparation method of an anti-lighting and resistance-reducing grounding module material. The anti-lighting and resistance-reducing grounding module material comprises calcined petroleum coke, special graphite powder, an ion slow-release agent and medium-temperature asphalt. The preparation method includes: mixing and kneading, forming, calcining and machining, wherein the mixing and kneading includes dry mixing and wet mixing, the special graphite powder, the calcined petroleum coke and the ion slow-release agent are added into a mixing and kneading pot for mixing and kneading during the dry mixing, dry mixing time is 60-70 minutes, dry mixing temperature is 135-145 DEG C, and the material obtained after the dry mixing is a dry material; the medium-temperature coal asphalt is added into the calcined petroleum coke after the dry mixing in twice to perform mixing and kneading during the wet mixing, wet mixing temperature is 145-155 DEG C, the weight of the medium-temperature coal asphalt added in the first time is 75-85% of the total weight of the medium-temperature coal asphalt, the time of the first wet mixing is 20-25 minutes, the weight of the medium-temperature coal asphalt added in the second time is 15-25% of the total weight of the medium-temperature coal asphalt, and the time of the second wet mixing is 25-30 minutes; a paste material is obtained after the mixing and kneading.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Preparation method for calcium silicate/polyolefin composite material

InactiveCN104403198AEvenly dispersedImprove bindingPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsCalcium silicatePolyolefin

The invention discloses a preparation method for a calcium silicate / polyolefin composite material. The method comprises the following steps: modifying calcium silicate to obtain active calcium silicate powder, dosing the active calcium silicate powder and polyolefin resin, mixing at the high speed, granulating, and forming to prepare the calcium silicate / polyolefin composite material. The method is simple to carry out, the physical and chemical property index of the material can be improved, the production costs of enterprises can be reduced, and the economic benefits of the enterprises can be increased.

Owner:HUNAN UNIV OF SCI & TECH

Method for producing biodiesel by using solid acid to catalyze waste animal and vegetable oils and fats

InactiveCN102181324AAcid value unlimitedRich sourcesFatty acid esterificationBiofuelsOil and greaseSodium methoxide

The invention provides a method for producing biodiesel by using solid acid to catalyze waste animal and vegetable oils and fasts, leftovers of the animal and vegetable oils and fats are taken as raw materials, a sodium bisulfate or zirconium sulfate catalyst and methanol or ethanol are added, and stirring reaction is performed under the conditions that the pressure is 0.2MPa and the temperature is 110-125 DEG C so as to reduce the acid value of a reaction product to below 2mg KOH / g; the residual methanol or the ethanol is recovered, 0.2% of sodium methoxide is further added, and the stirringreaction is performed for 30 minutes at the temperature of 60-65 DEG C; and performing decompression distillation on the reaction product so as to get the biodiesel. The sources of the raw materials are abundant, and the price is low. Compared with the traditional esterification method or the ester exchange method for producing the biodiesel, the process uses the solid acid to replace concentrated sulfuric acid for being used as the catalyst; furthermore, the using quantity of organic base is small, the environmental pollution is small, the equipment corrosivity is small, and the sewage treatment cost is reduced. By adopting the method, not only resources are saved, but also the environmental pollution problem caused by the leftovers generated during refining of vegetable oil at present is eliminated, and waste is further changed to a valuable matter.

Owner:杨大伟

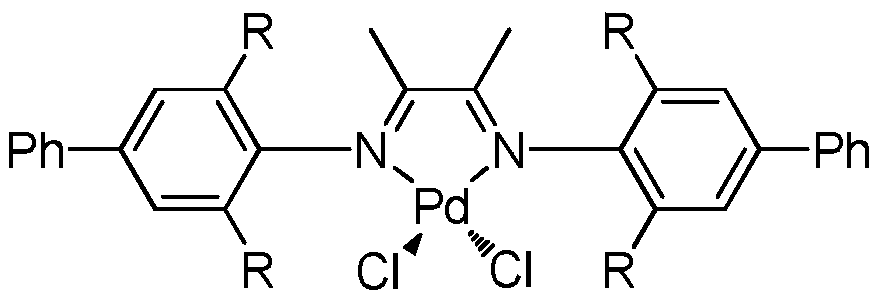

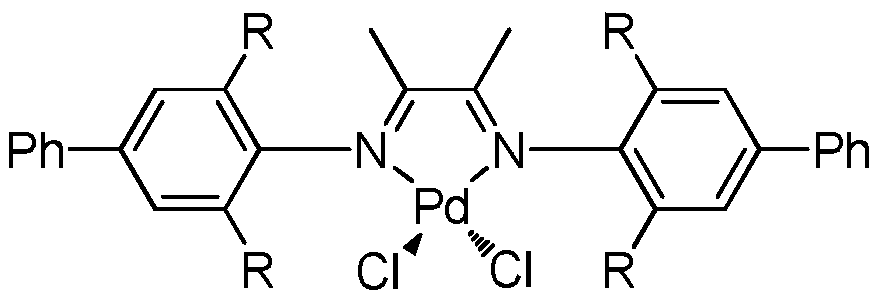

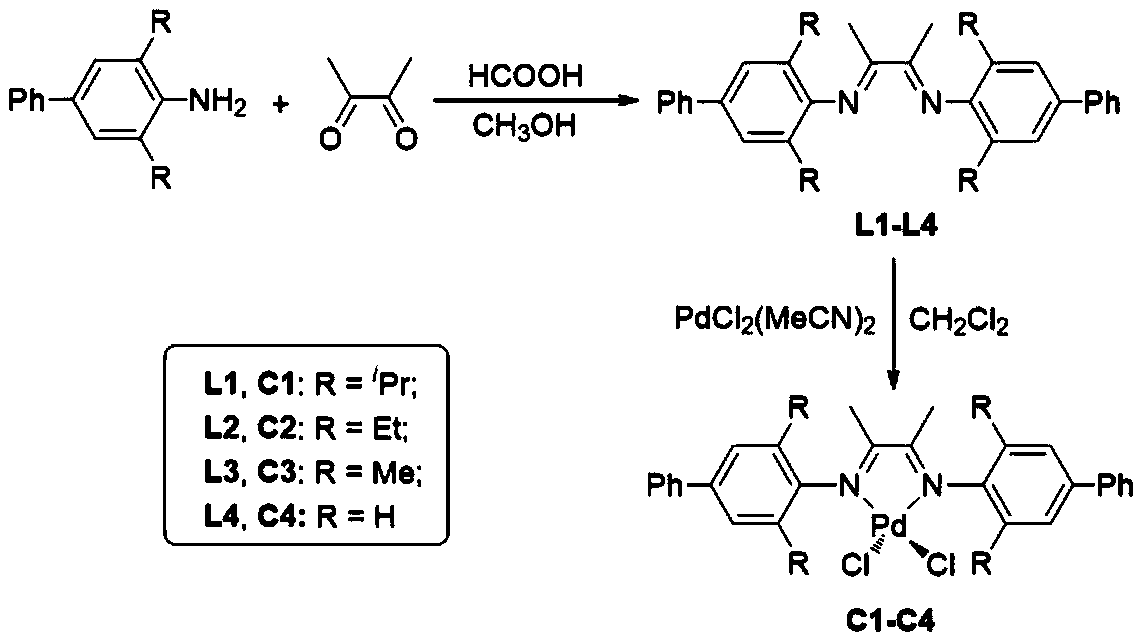

P-phenyl substituted alpha-diimine palladium catalyst and preparation method thereof

InactiveCN110339862AChange spaceChange densityGroup 8/9/10/18 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEvaporationPalladium catalyst

The invention discloses a p-phenyl substituted alpha-diimine palladium catalyst and a preparation method thereof. The preparation method comprises the following steps: adding a p-phenyl substituted aniline derivative and 2,3-butanedione into a dry flask, carrying out a reflux reaction by taking absolute methanol as a solvent and formic acid as a catalyst to obtain a precipitate, recrystallizing the obtained crude product through a mixed solvent, carrying out filtering, carrying out washing with cold ethanol, and carrying out vacuum drying to obtain a p-phenyl substituted alpha-diimine ligand;and under protection of N2, mixing the p-phenyl substituted alpha-diimine ligand with PdCl2(MeCN)2, adding CH2Cl2, carrying out stirring for reacting, filtering the mixed solution, removing the solvent of the obtained liquid by rotary evaporation, washing the obtained solid with diethyl ether, and finally carrying out vacuum drying to obtain the catalyst. The catalyst disclosed by the invention isapplied to an alpha-olefin polymerization reaction, and polyalpha-olefin (PAO) lubricating oil base oil obtained through a polymer has the advantages of low pour point, high viscosity index and the like, so that the use effect of PAO lubricating oil is greatly improved, and use requirements on the market are met.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

Additive for producing biologic diesel oil directly from grease of animals and plants, and biologic diesel oil prepared by the additive

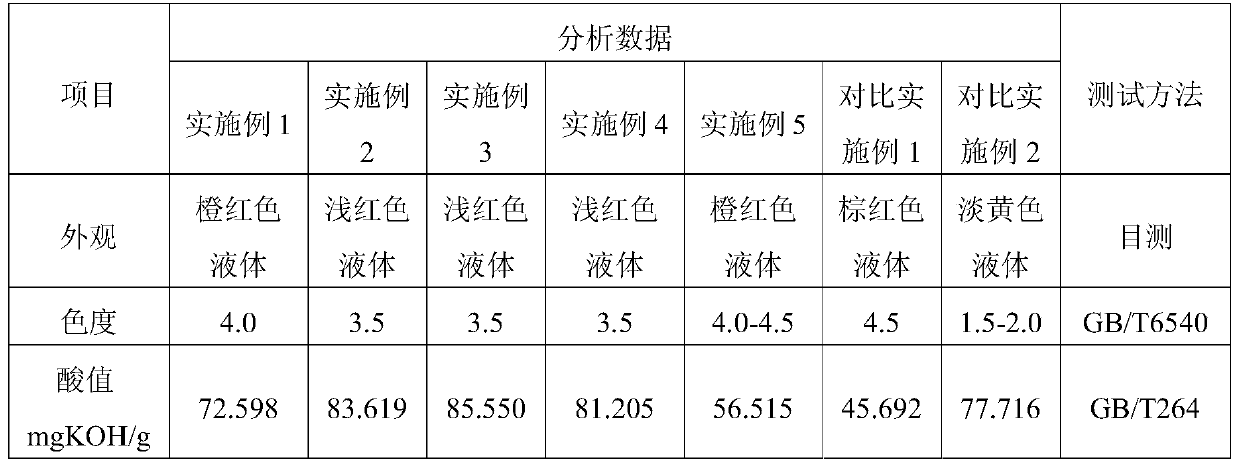

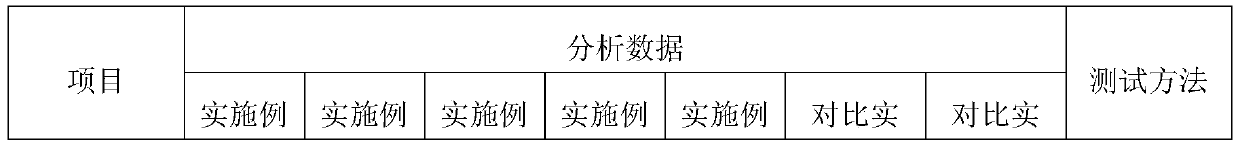

InactiveCN101050376AImprove physical and chemical performance indicatorsHigh calorific valueBiofuelsLiquid hydrocarbon mixture productionChemistryEthylene glycol monomethyl ether

This invention discloses an additive for producing biosiesel oil from animal and plant oils. The additive is prepared from: dimethyl carbonate 35-45 wt.%, KOH 10-15 wt.%, catalyst 0.75-1.25 wt.%, saponification inhibitor 8.25-13.75 wt.%, chain-breaking agent 6-10 wt.%, and ethylene glycol monomethyl ether 30-40 wt.%. The obtained biodiesel oil comprises animal and plant oils, diesel oil and additive at a weight ratio of (30-60) :( 38-65) :( 2-5).

Owner:曹志德

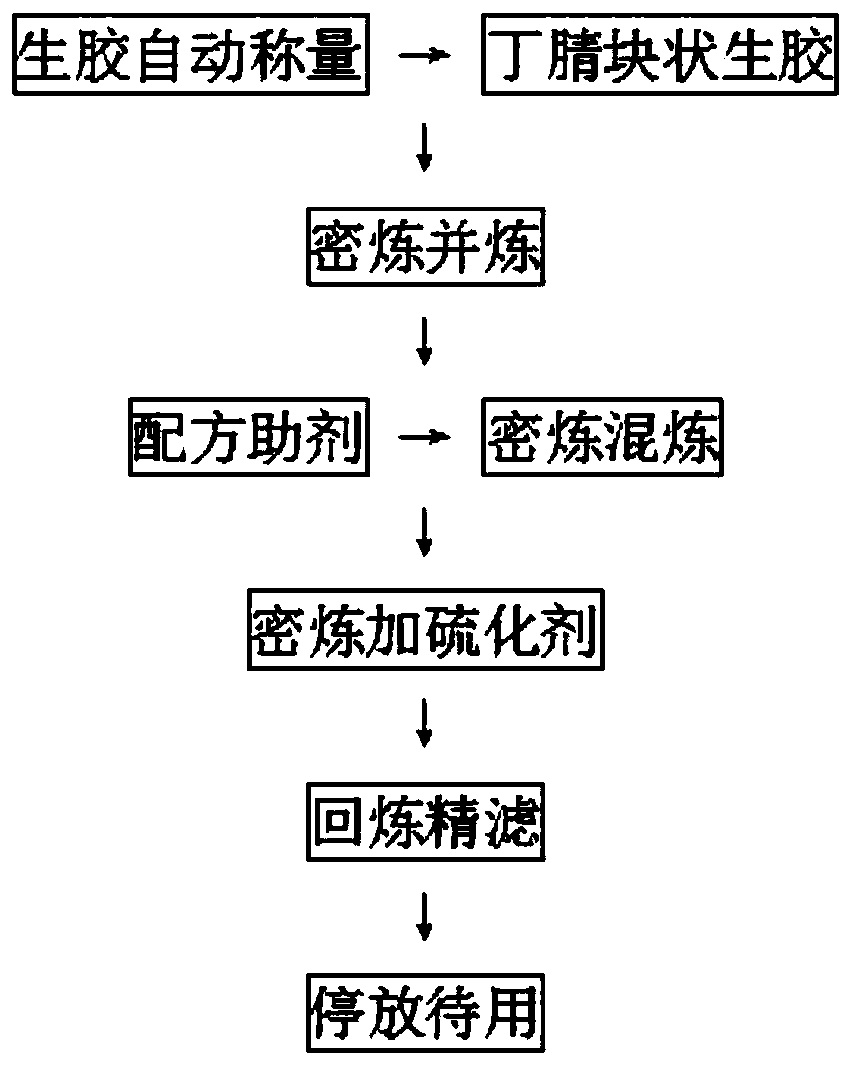

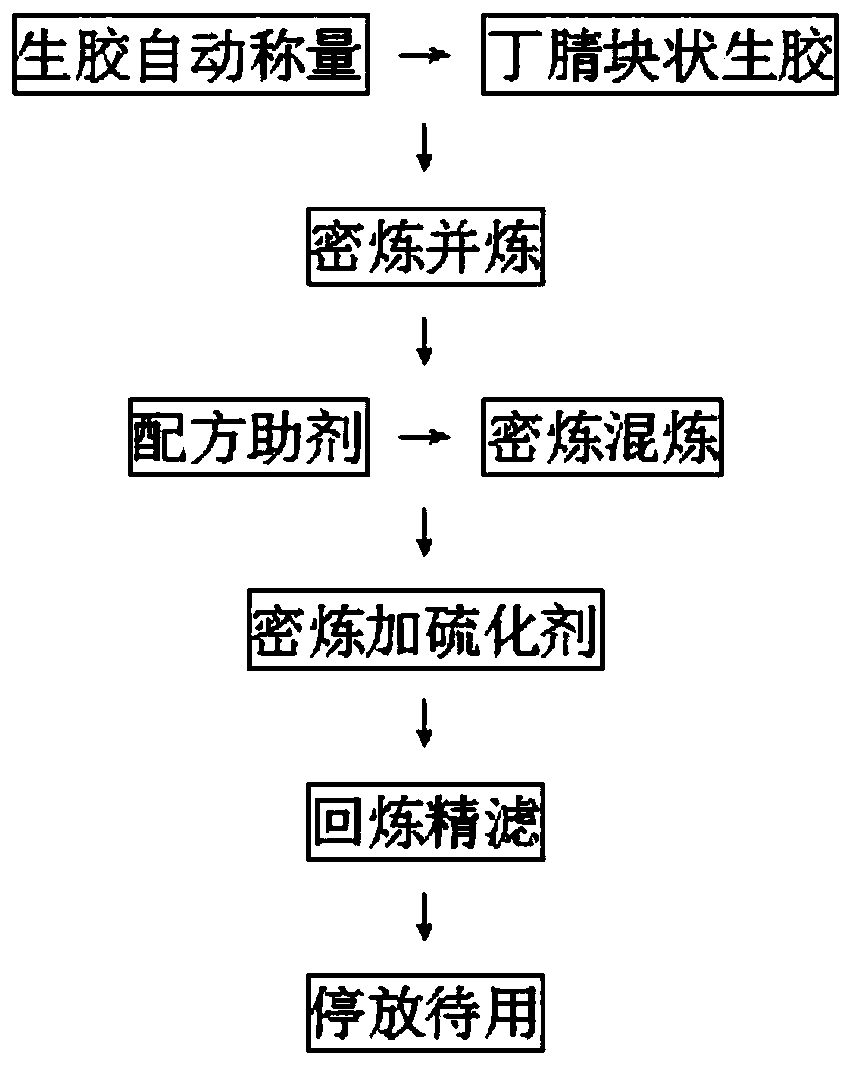

Anti-entangling and anti-damage rubber covered roller formula for spinning production and rubber compound preparation process thereof

The invention provides an anti-entangling and anti-damage rubber covered roller formula for spinning production and a rubber compound preparation process thereof. The rubber covered roller comprises an aluminum tube roller core and a rubber composite material layer for coating the aluminum tube roller core. The rubber composite material layer is prepared from the following raw materials in parts by weight: 40-60 parts of carboxyl hydrogenated nitrile rubber, 40-60 parts of nitrile rubber, 5 parts of zinc oxide, 10 parts of titanium dioxide, 1.5 parts of an antiageing agent, 3-4 parts of an accelerant, 1-3 parts of an antistatic agent, 8-14 parts of an antistatic plasticizer, 1-3 parts of a functional auxiliary agent, 6-12 parts of white carbon black and 1-3 parts of a vulcanizer. The anti-entangling and anti-damage rubber covered roller formula can improve the oil resistance of the spinning rubber covered roller, prevent permeation of an oiling agent and prevent migration of a dye frompolluting the surface of the rubber covered roller. In the preparation process, a rubber plasticizing process in a conventional preparation process is canceled. A novel process of directly putting rubber (blocky rubber) into an internal mixer to be mixed to form a rubber compound is adopted, so that the process flow is shortened, the operating strength is reduced and the production efficiency isimproved.

Owner:WUXI NO 2 RUBBER

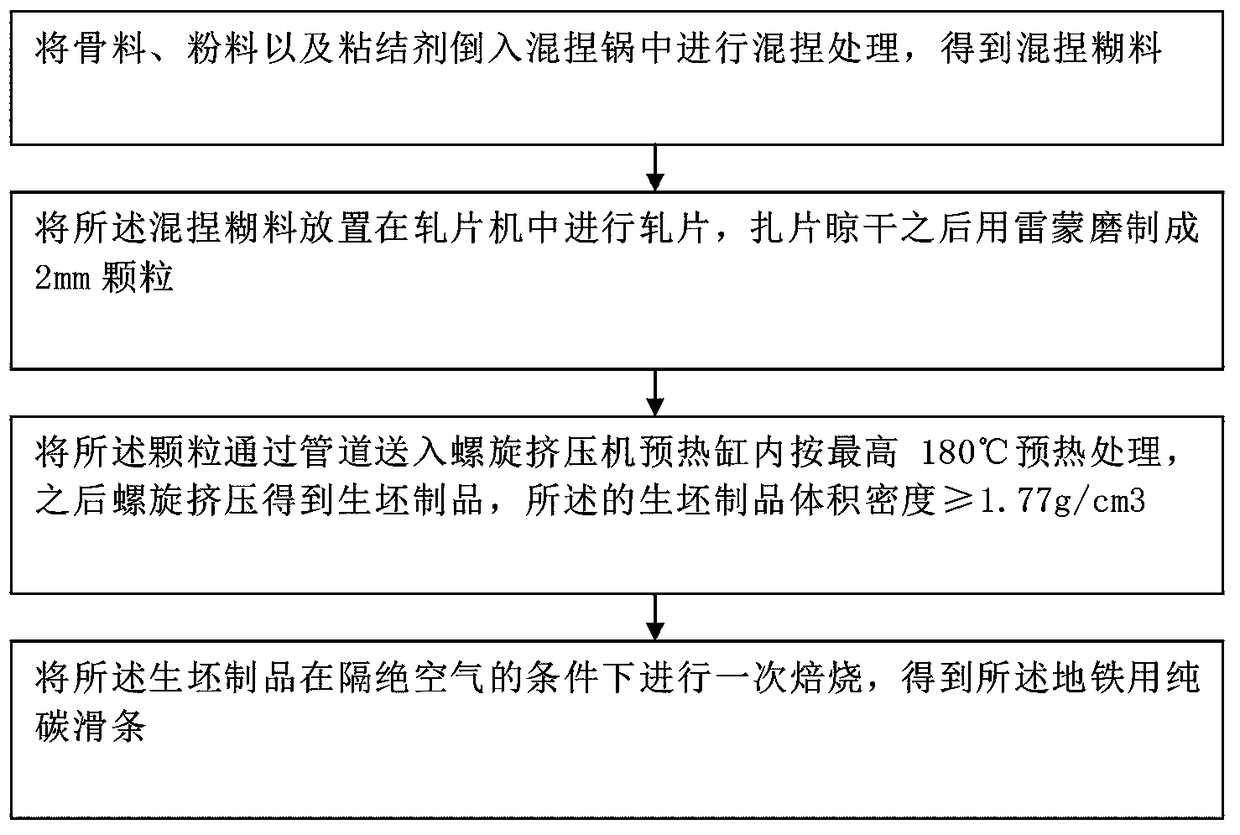

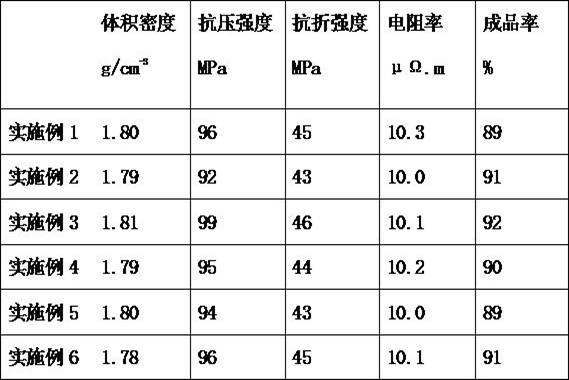

Pure-carbon draw runner for subway and preparation method of pure-carbon draw runner

InactiveCN109265171AImprove performanceImprove conductivityRailway vehiclesPower current collectorsAdhesiveCarbon product

An embodiment of the invention provides a pure-carbon draw runner for a subway and a preparation method of the pure-carbon draw runner. The method comprises the following steps: pouring aggregates, powder and an adhesive in a mixing and kneading machine and carrying out mixing and mixing treatment to obtain mixed and kneaded paste; placing the mixed and kneaded paste in a sheet mill and rolling, and after air-drying sheets, preparing the sheets into particles with the sizes of 2 mm by using a Raymond mill; feeding the particles into a preheating cylinder of a screw extruder by a pipe and carrying out preheating treatment at the highest temperature of 180 DEG C, and then carrying out screw extrusion to obtain a blank product, wherein the volume density of the blank product is greater than or equal to 1.77 g / cm<3>; and primarily roasting the blank product under the condition that the blank product is isolated from air to obtain the pure-carbon draw runner for the subway. A pantograph carbon draw runner material produced by the preparation method of the pure-carbon draw runner for the subway provided in the second aspect is a novel carbon product, and has quite good physico-chemical performance indexes, due to addition of silicon carbide, the conductivity, heat conduction property, friction property and wear resistance of the pantograph carbon draw runner material are improved remarkably, and the overall performance of the pure-carbon draw runner is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Preparation method of LFP (lithium ferric phosphate) electrode material

InactiveCN104241607AQuality improvementReduce energy consumptionCell electrodesSecondary cellsSolubilityMolten state

The invention discloses a preparation method of an LFP material. The preparation method comprises the following steps of (1) feeding the raw materials for preparing the LFP material into a smelter, then heating the raw materials into a molten state and enabling the molten raw materials to flow out; (2) quenching the out-flow molten materials in water and then drying the quenched materials; (3) performing superfine processing and then carbon coating on the dried materials. The preparation method of the LFP electrode materials can achieve continuous production of the LFP material and meanwhile is stable in quality and low in energy consumption. Compared with an existing liquid phase method capable of achieving mass production, the preparation method of the LFP electrode material is equivalent in physical and chemical performance index but simpler in production process, free from restriction of water solubility, lower in energy consumption and production cost and applicable to a mass production non-heavy waste water treatment process; compared with a solid phase method, the preparation method of the LFP material is complete in reaction degree, high in production efficiency and obvious in enhancement of physical and chemical performance indexes. By contrast, the solid phase method lags in technology and falls into disuse. Technological processes and equipment utilized in the preparation method of the LFP material are mature and well-used, thereby facilitating control and adjustment of production processes and product quality.

Owner:威远县大禾陶瓷原料有限公司

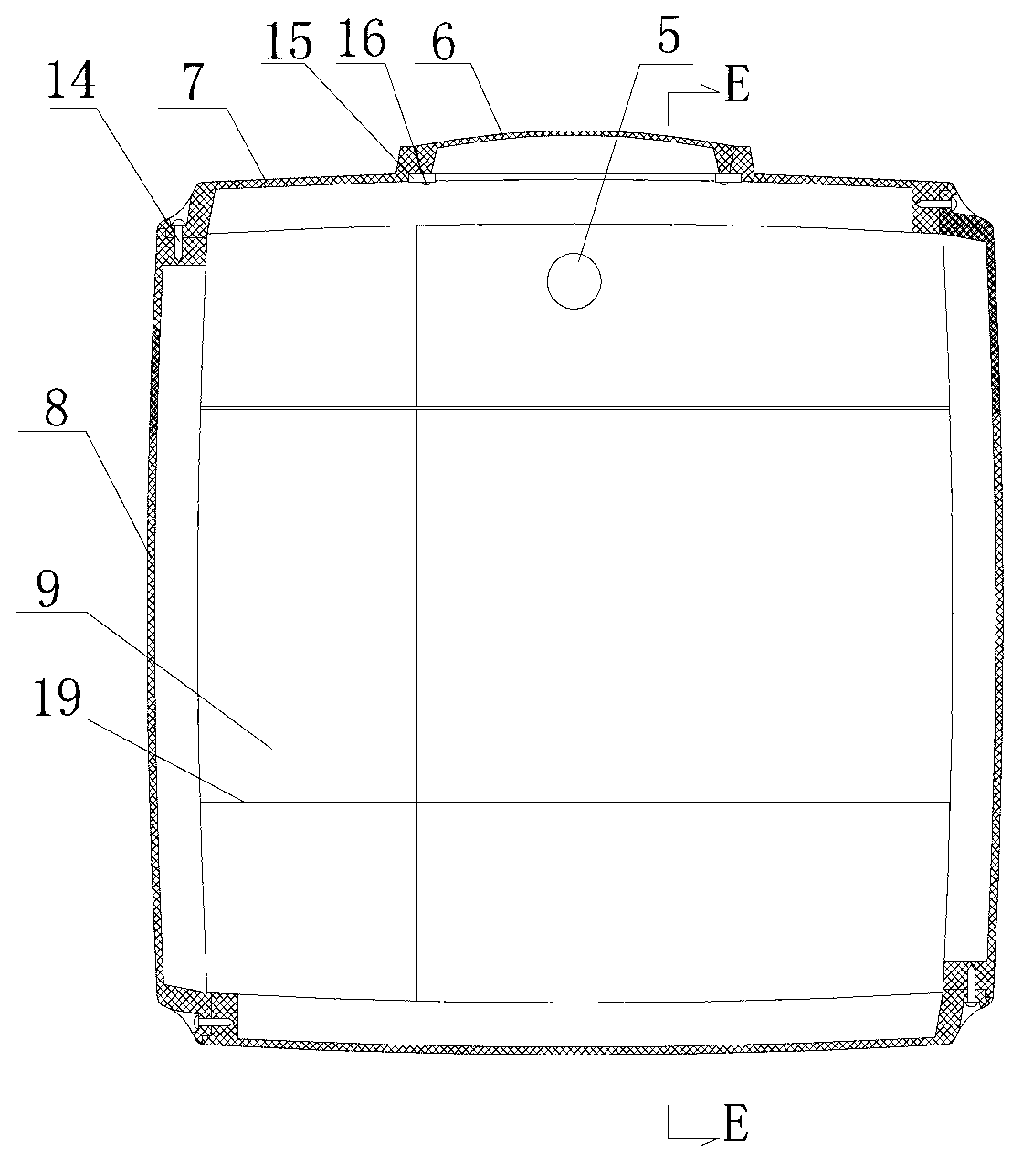

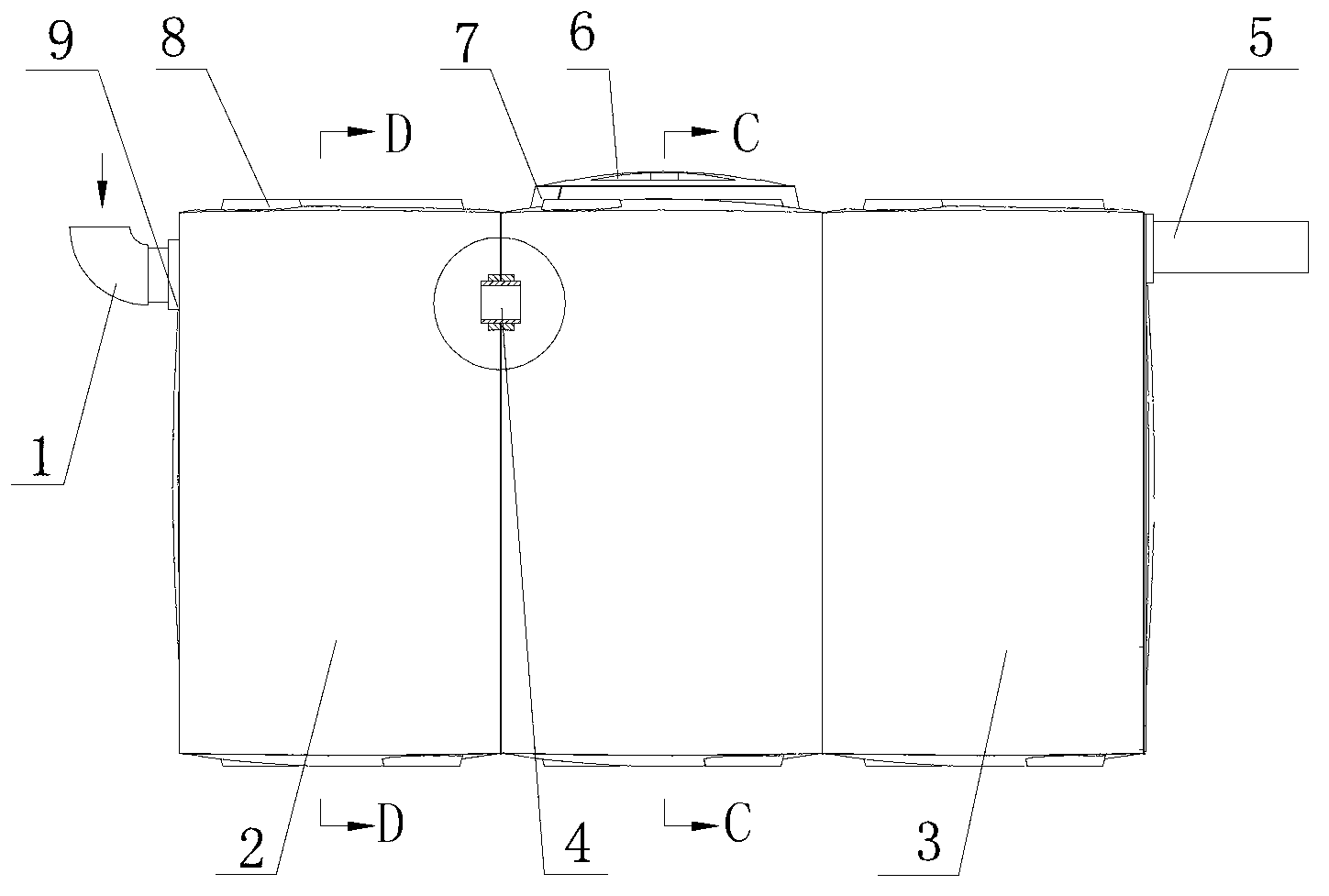

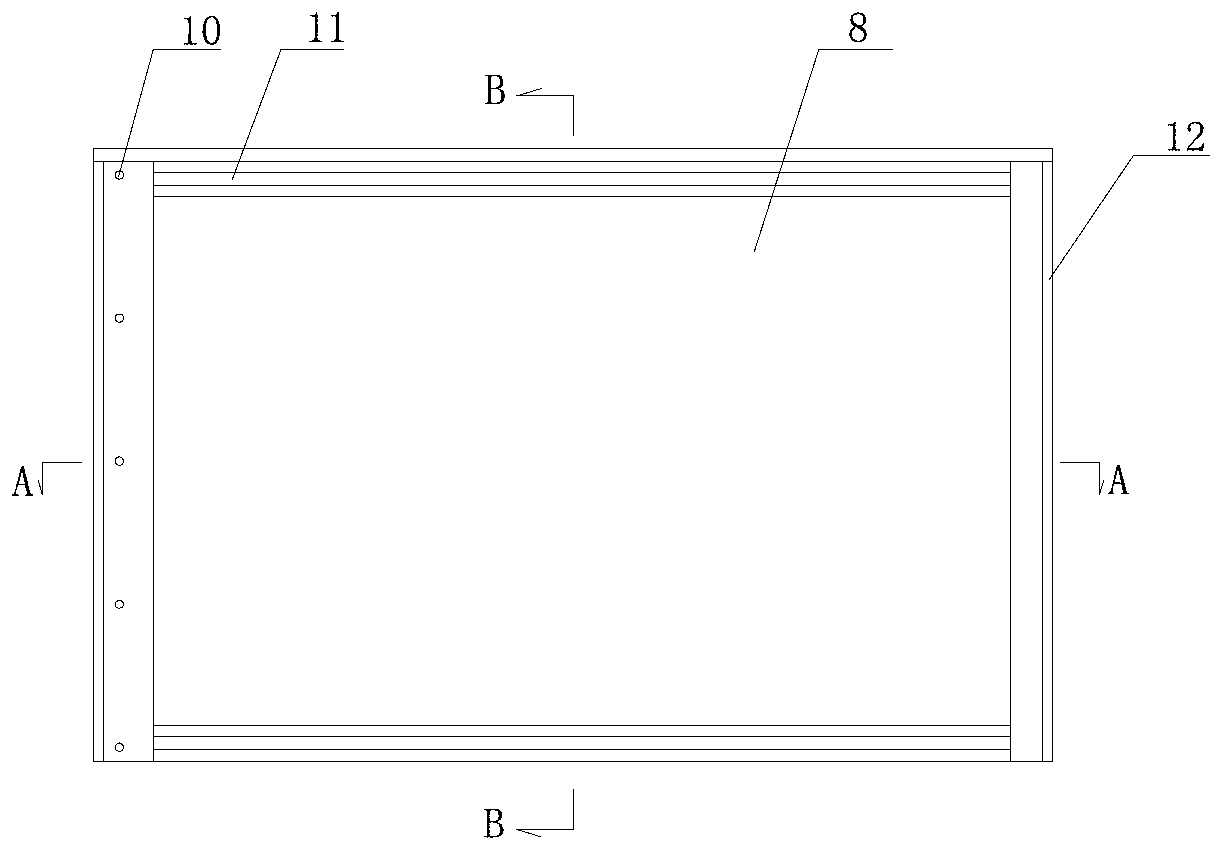

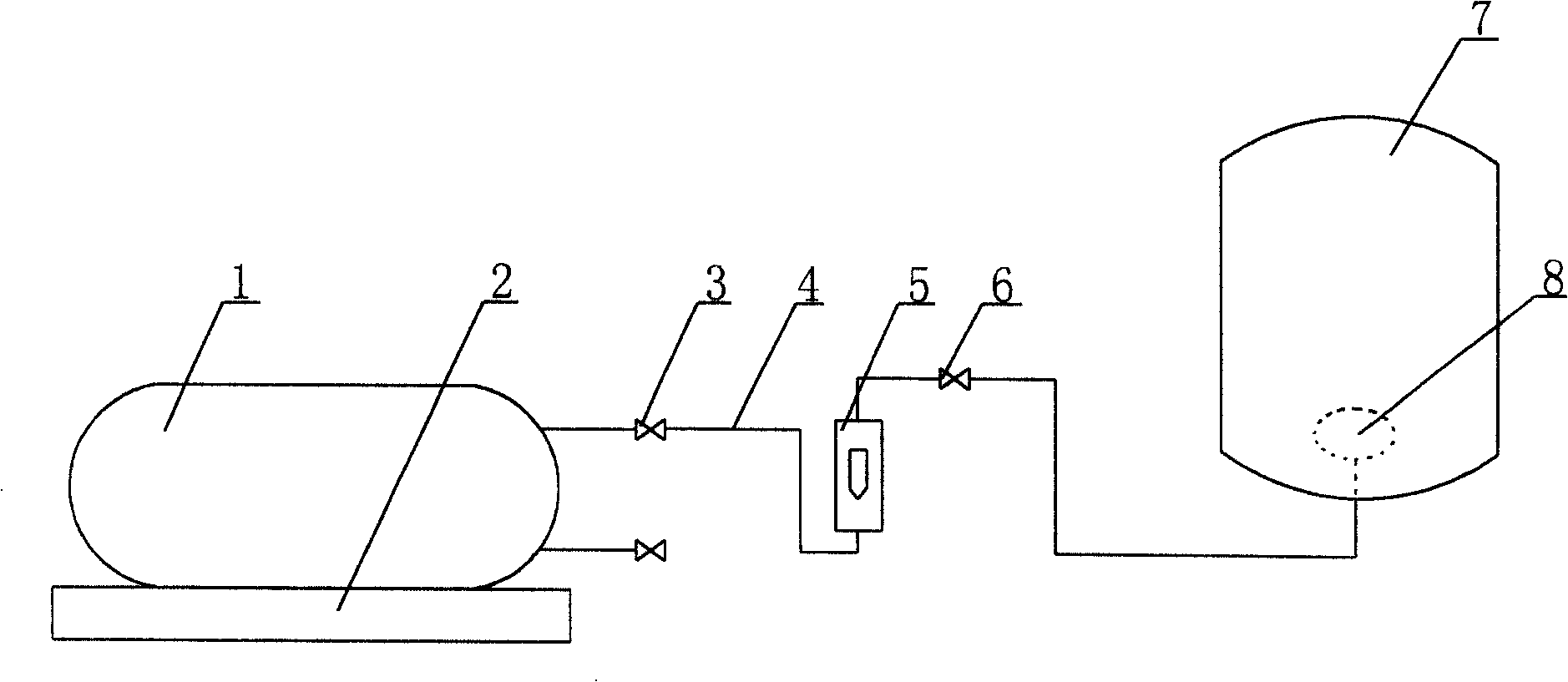

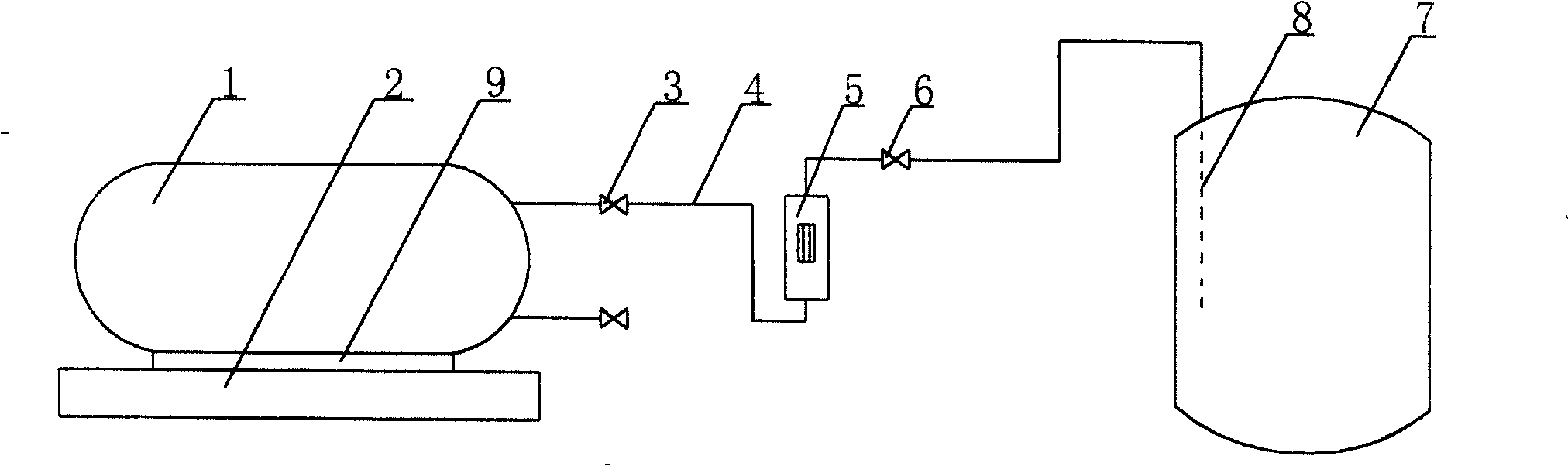

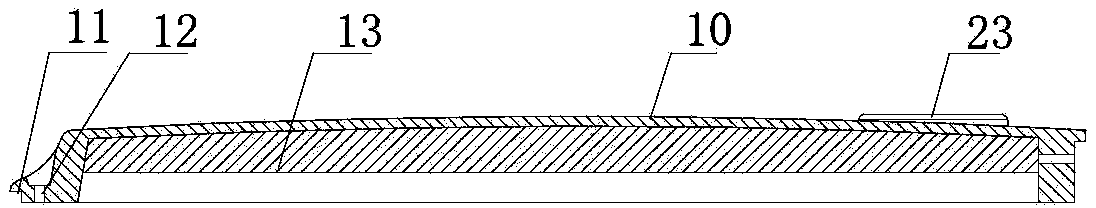

Four-module assembled water cellar

InactiveCN103015779AImprove physical and chemical performance indicatorsFor long-term storageBulk storage containerPipingWater resource management

The invention discloses a four-module assembled water cellar, which comprises a settling pond and a water cellar, wherein the settling pond is provided with a water inlet pipe, a pipe is communicated between the settling pond and the water cellar, and the upper part of the water cellar is provided with a water outlet pipe; and the settling pond and the water cellar are assembled by modules. An integrally formed water cellar is divided into a plurality of standard modules so as to achieve the perfect combination of minimum mould number and minimum mould cost to complete the production of the whole device, and the size of the water cellar can be expanded in multiple specifications on the basis of the standard modules.

Owner:XIANGTAN KODARLY IND

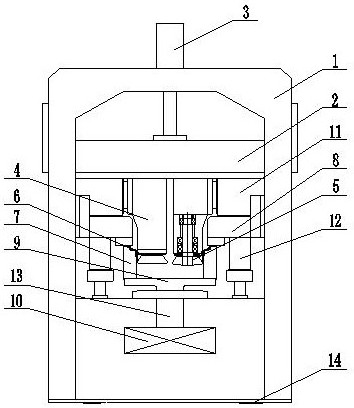

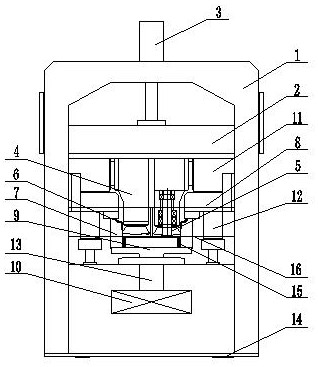

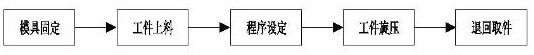

Universal internal rotation machine device for engineering wheels and machining method thereof

PendingCN112845784ACompact structurePrecise processing sizeMetal-working feeding devicesRimsPhysicsAutomatic control

The invention provides a universal internal rotation machine device for engineering wheels. The universal internal rotation machine device for engineering wheels comprises a frame, a sliding block, a spinning roller mechanism, a pressing mechanism and a rotating platform are arranged in the frame, and the upper end of the sliding block is connected with an axial feeding mechanism. The lower end of the sliding block is connected with the spinning roller mechanism, and a spinning roller is arranged at the bottom of the spinning roller mechanism. A mold is fixed on the rotating platform, and the rotating platform is connected with a transmission mechanism through a main shaft. The pressing mechanism is connected with a pressing cylinder, and a workpiece is fixed in the mold through the pressing mechanism. The spinning roller mechanism is further connected with a radial feeding mechanism, and the axial feeding mechanism and the radial feeding mechanism are matched with an automatic control numerical control system to achieve feeding machining according to a product curve. The invention further provides a method for machining wheels through the universal internal rotation machine device for engineering wheels. The method specifically comprises the steps of mold fixing, feeding, spinning roller internal spinning, returning and workpiece taking and the like, unequal-thickness extension machining on engineering wheels can be completed, and the universal internal rotation machine device can be widely applied to the field of machining of rims of engineering wheels.

Owner:杭州润德车轮制造有限公司

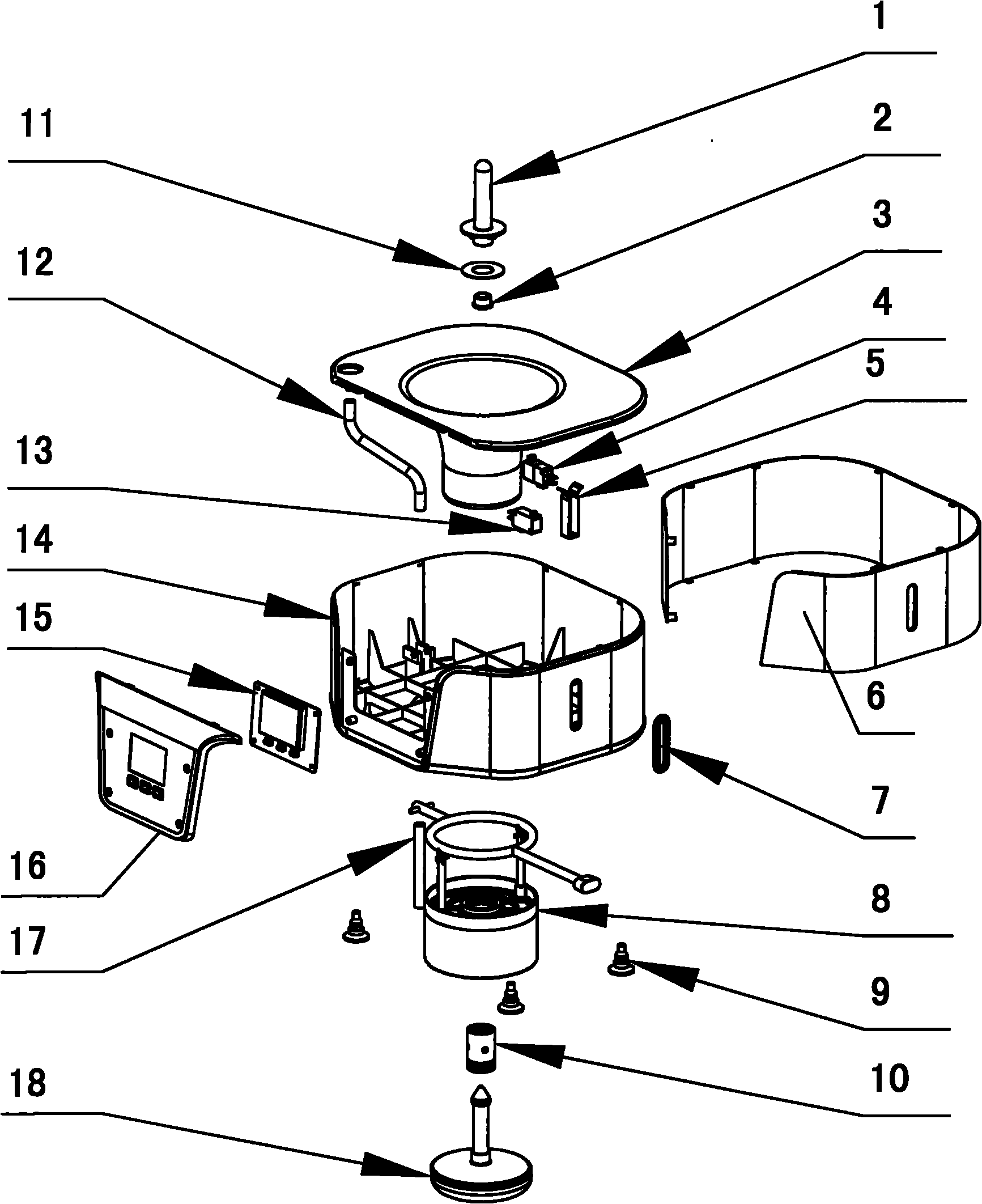

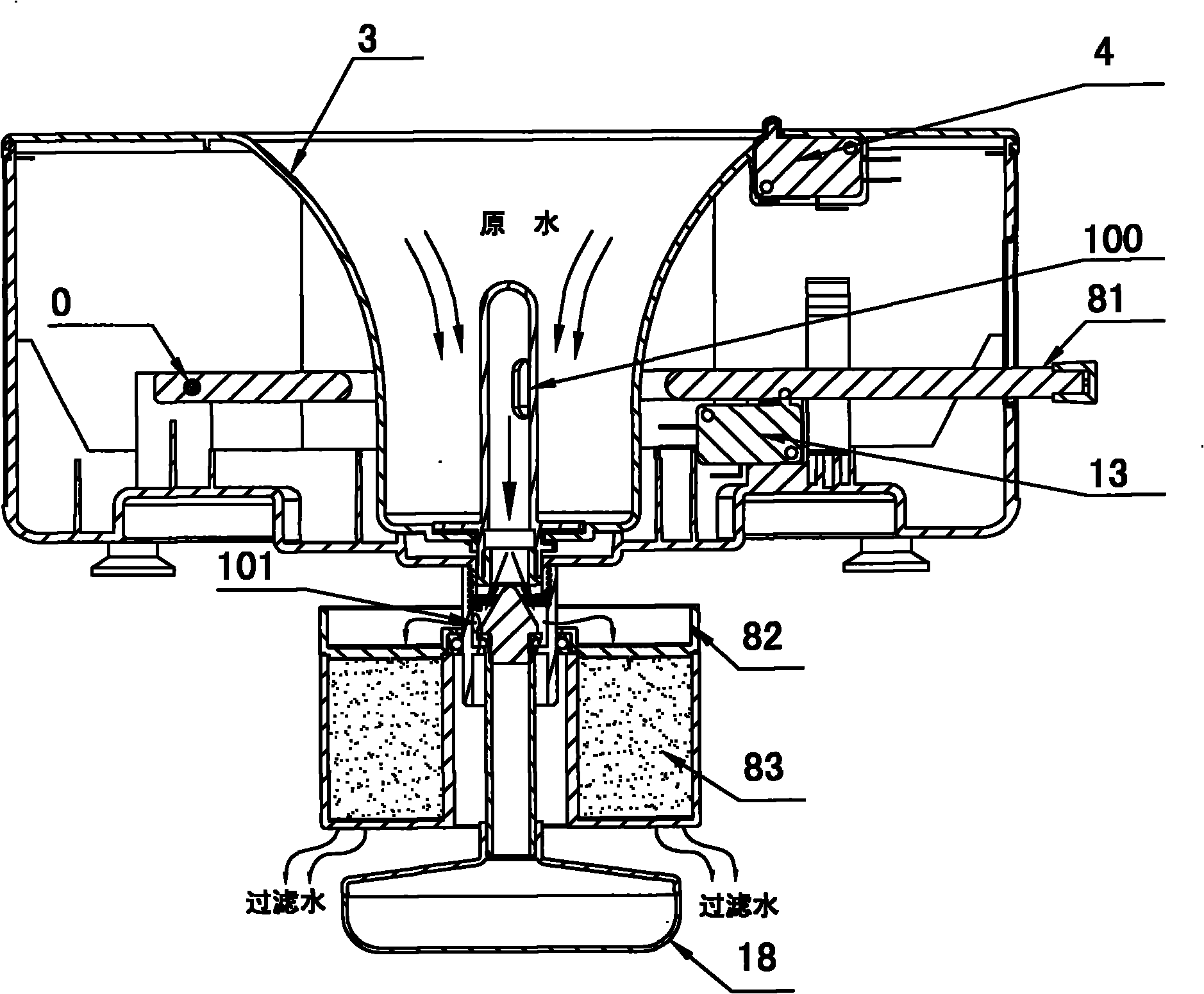

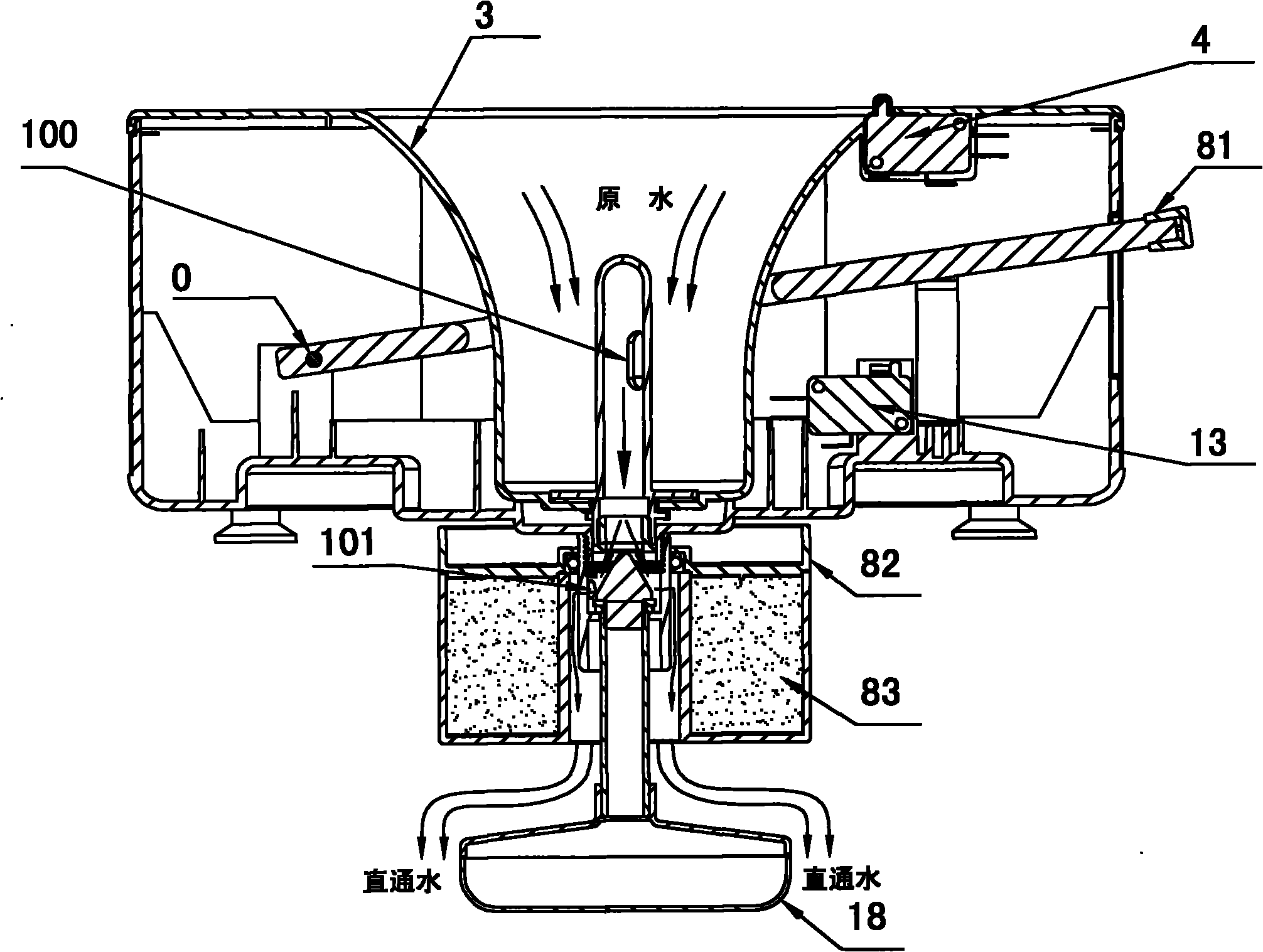

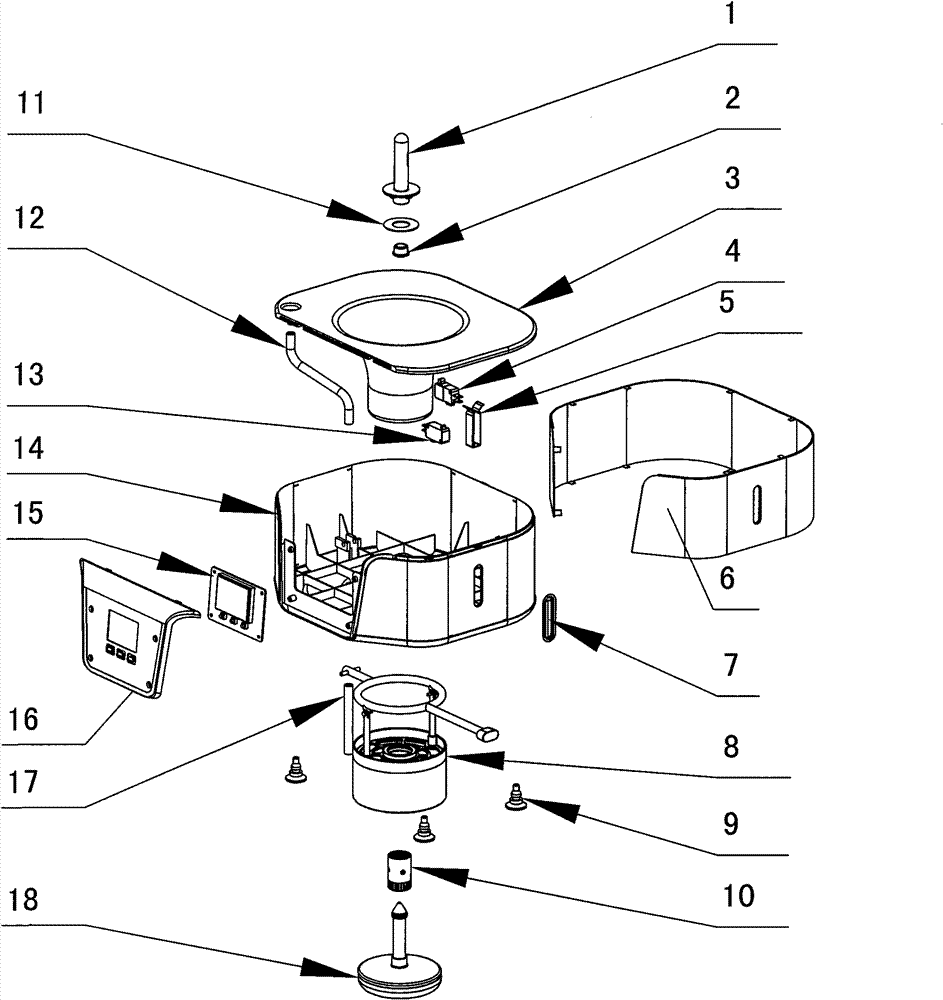

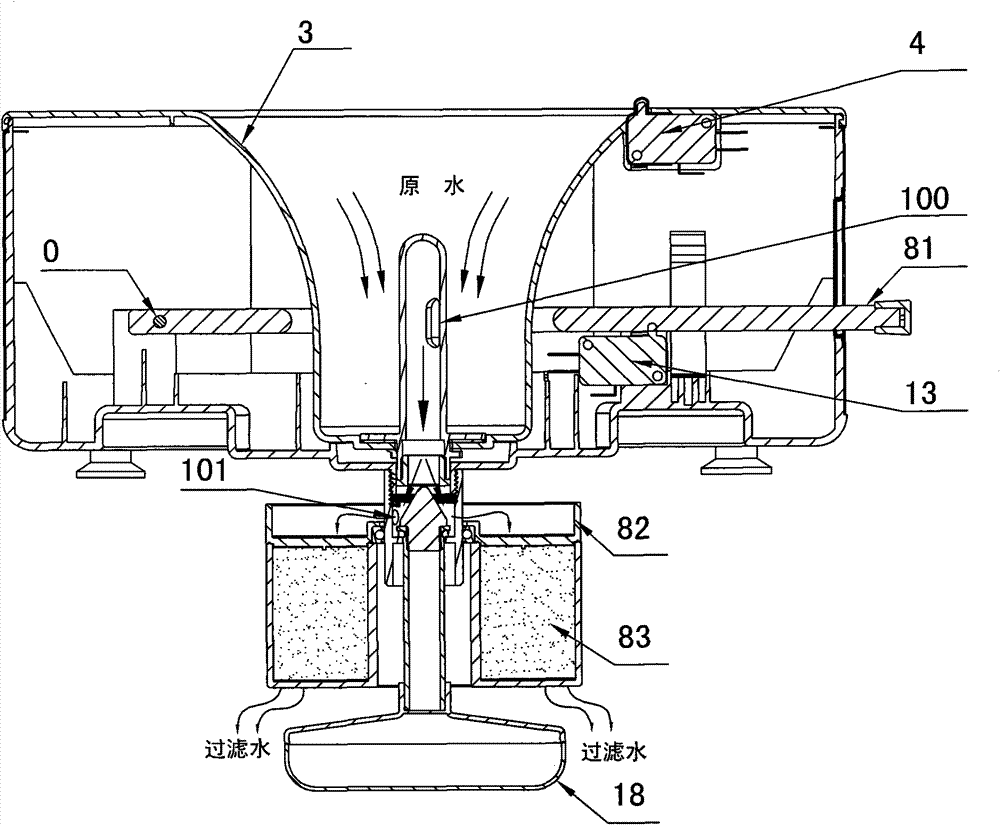

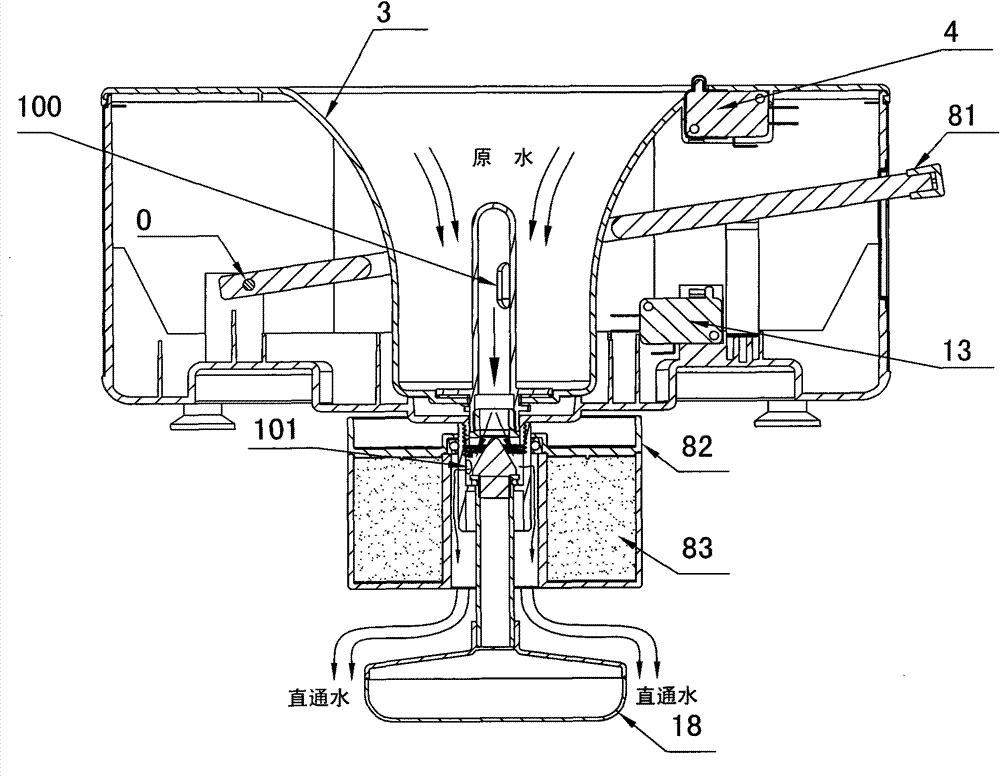

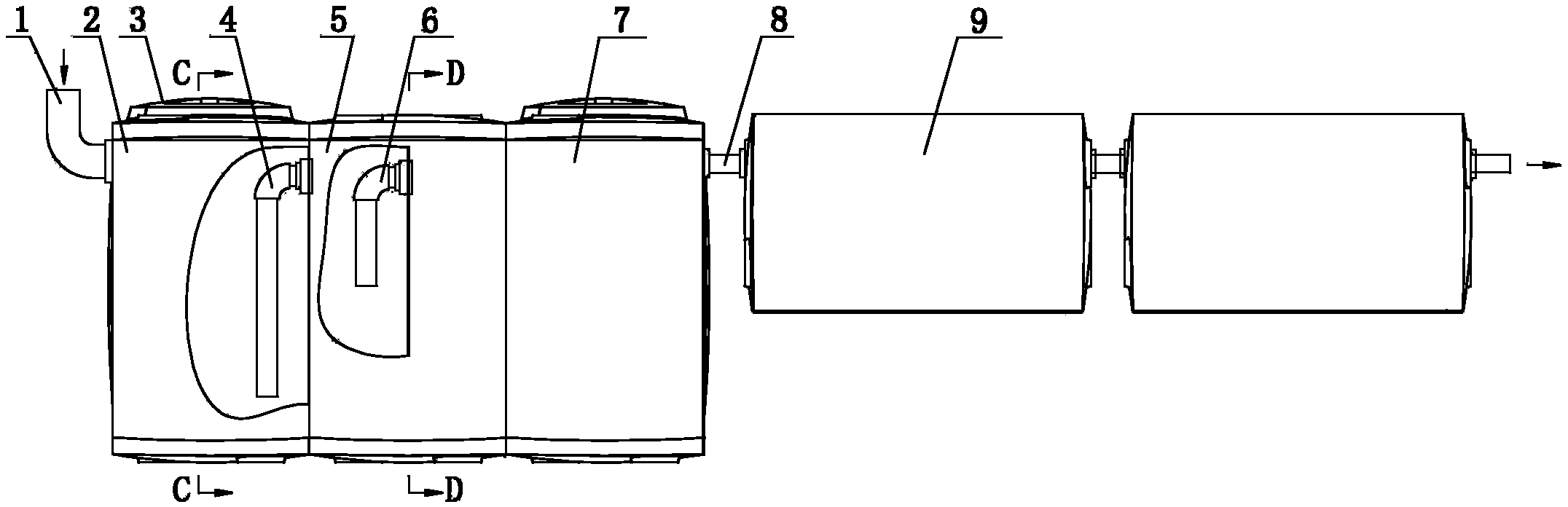

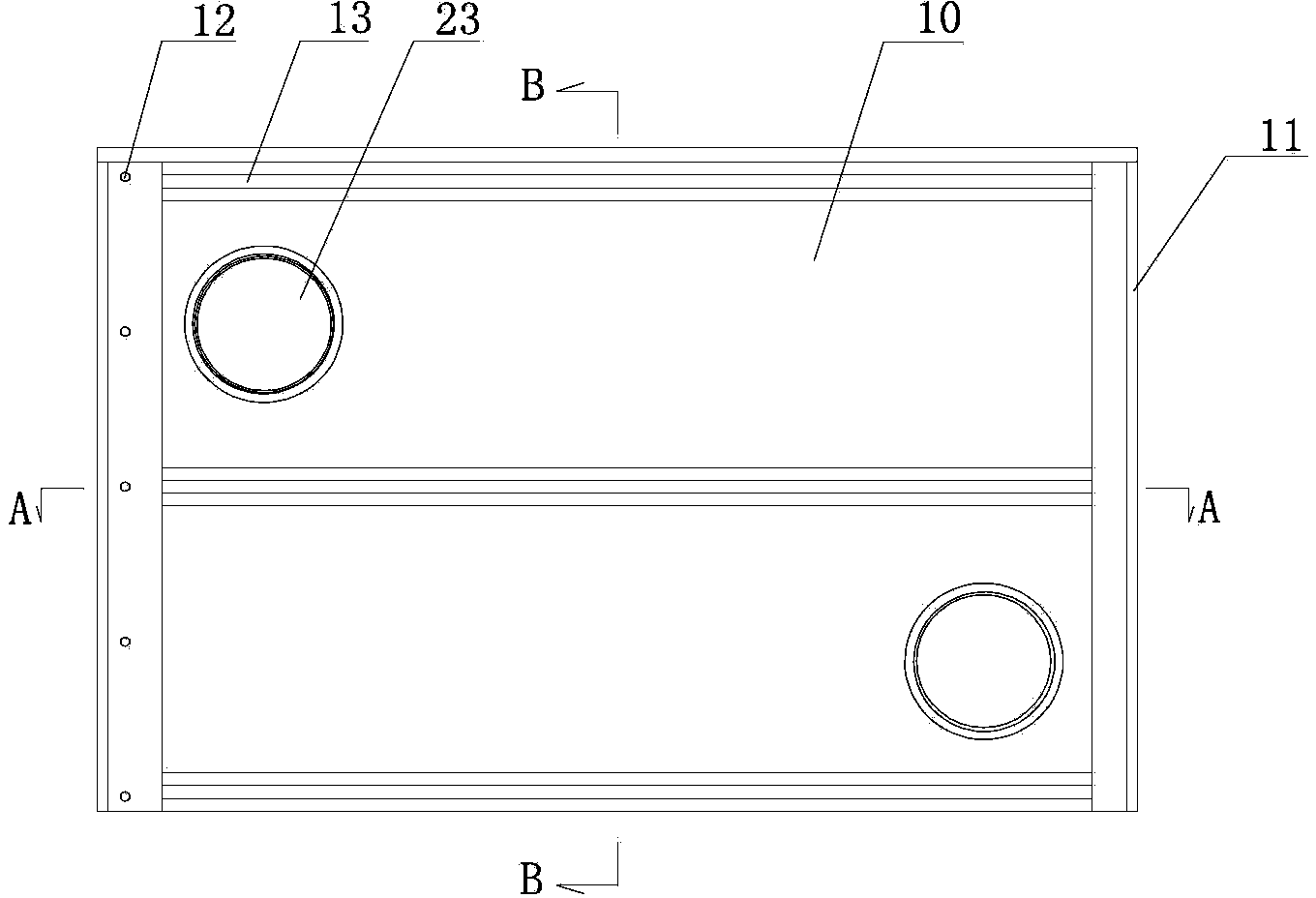

Micro-electrolysis water generator

InactiveCN102050507AImprove physical and chemical performance indicatorsWater/sewage treatmentElectrolysisPollution

The invention provides a micro-electrolysis water generator, which is matched with a water dispenser or is used independently, and can generate drinking water which is beneficial to human bodies, such as alkaline electrolysis water. In the micro-electrolysis water generator, the water dispenser is convenient to clean, and the secondary pollution of the water dispenser is prevented. The micro-electrolysis water generator comprises a smart seat component, a water inlet component, a water outlet component, a filter element component and a floater component, wherein the water inlet cavity is formed on the middle part of the smart seat component; the water inlet component is fixed on the middle part at the bottom end of the smart seat component and is positioned in the water inlet cavity, and the water inlet component is provided with a water inlet; the filter element component is positioned below the smart seat component; the outlet of the water inlet component is communicated with the water outlet component; the water outlet of the water outlet component is communicated with the filter element component; the filter element component comprises a middle part through hole; a filter element is positioned on the periphery of the middle part through hole; the water outlet component is positioned in the middle part through hole of the filter element component; and the top of the floatercomponent is fixed in an inner cavity of the water outlet component, and the floater component comprises a floater positioned below the filter element component.

Owner:珠海天睿生物科技有限公司

Production process of isostatic pressing special graphite

The present invention discloses an isostatic pressing special graphite production process, which comprises crushing, grinding, mixing kneading, screening, isostatic pressing molding, roasting, dipping and graphitizing, and the used raw materials comprise calcined coke, pitch coke and modified pitch. The modified asphalt powder is adopted as a binder, the calcined coke powder, the asphalt coke powder and the modified asphalt powder are simultaneously added into a kneading machine to be stirred and kneaded in the kneading process, the asphalt is gradually melted and uniformly permeates into the calcined coke and the asphalt coke powder along with the increase of the temperature, and part of the asphalt uniformly coats the surfaces of the calcined coke and the asphalt coke powder, so that the surface of the calcined coke and the surface of the asphalt coke powder are uniformly coated with the modified asphalt powder. Therefore, not only is an independent asphalt melting step omitted, but also asphalt distribution is more uniform, so that the finished product rate and physical and chemical performance indexes of products are improved.

Owner:永安市鼎丰碳素科技有限公司

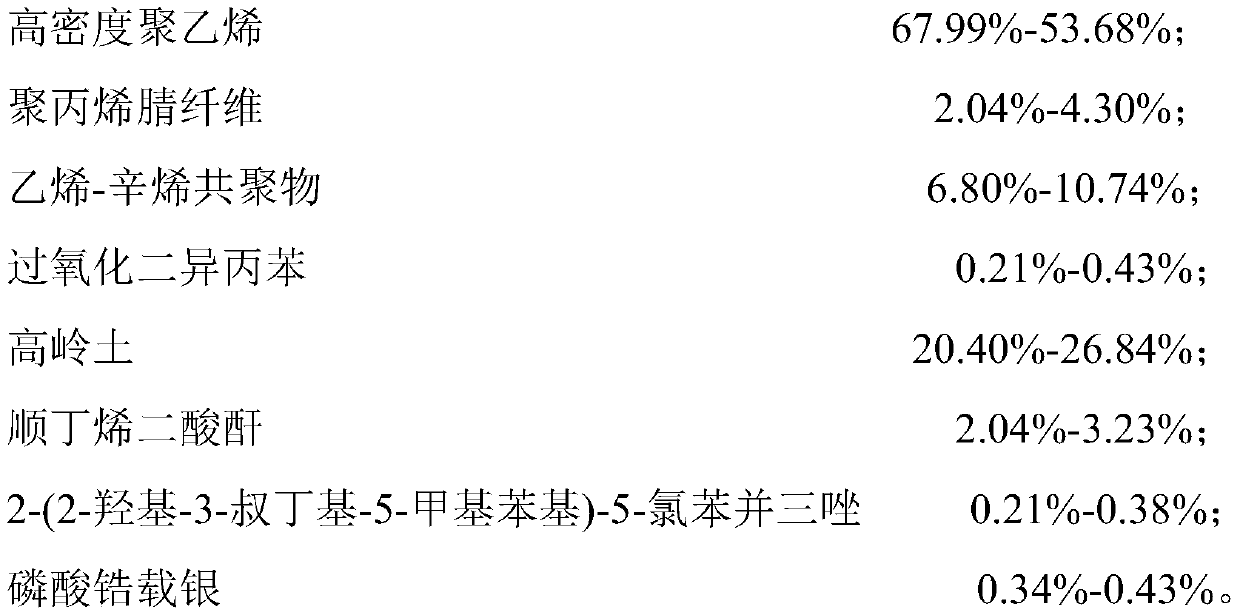

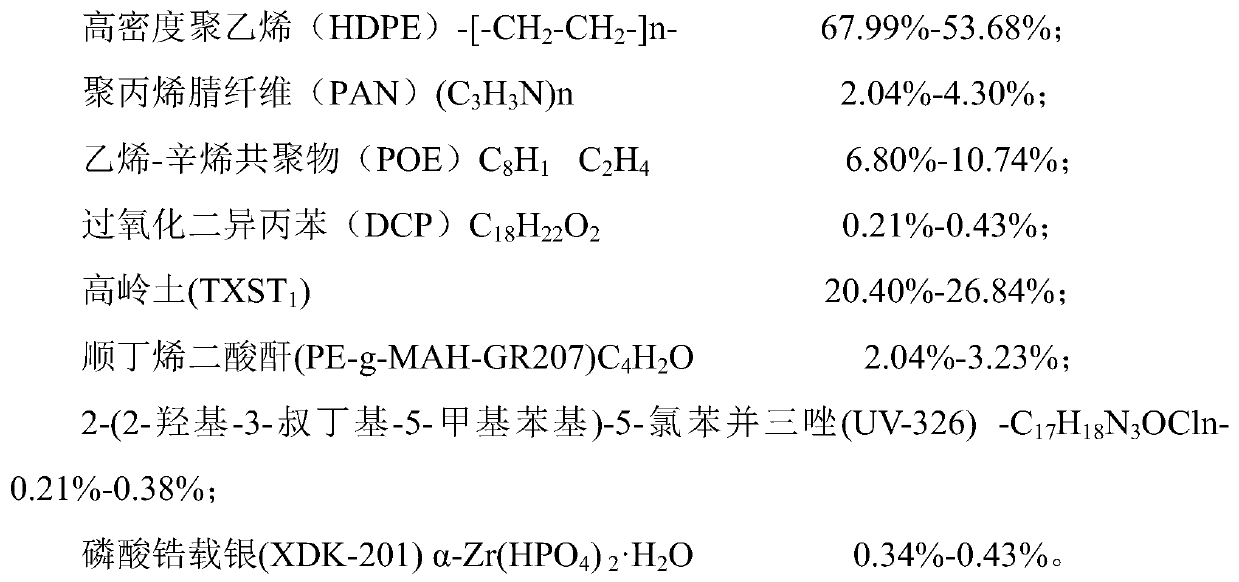

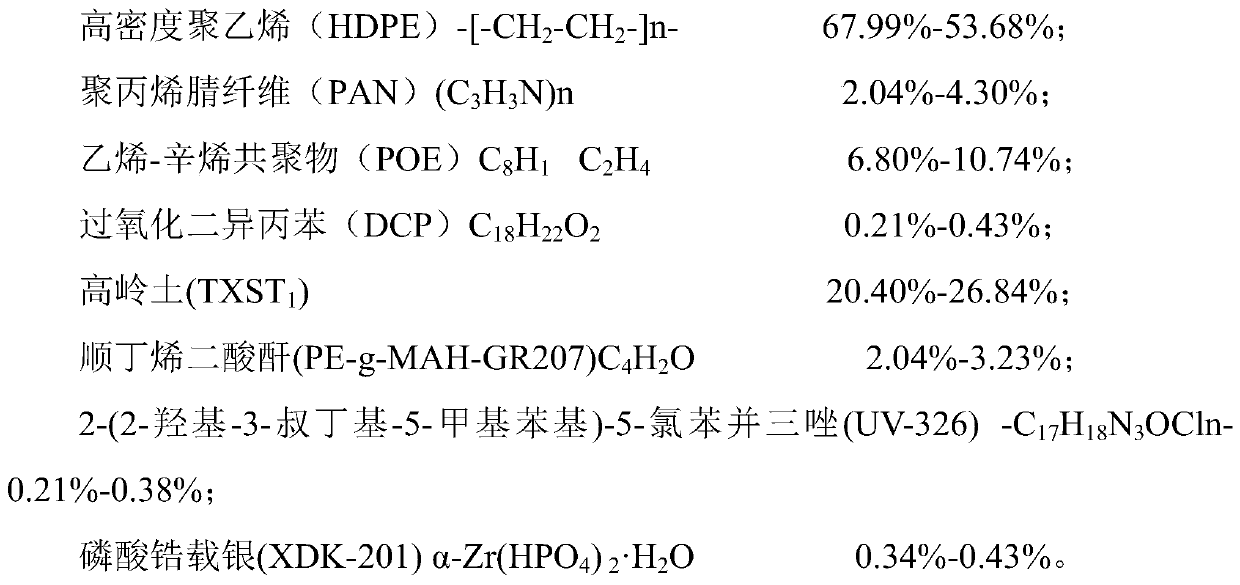

Mixed material for manufacturing high-density polyethylene double-wall corrugated pipe and preparation method thereof

InactiveCN111440379AImprove physical and chemical performance indicatorsExtended service lifePolymer scienceChlorobenzene

The invention provides a mixed material for manufacturing a high-density polyethylene double-wall corrugated pipe and a preparation method thereof, and the mixed material comprises the following components in percentage by weight: 67.99%-53.68% of high-density polyethylene; 2.04%-4.30% of a polyacrylonitrile fiber; 6.80%-10.74% of an ethylene-octene copolymer; 0.21%-0.43% of dicumyl peroxide; 20.40%-26.84% of kaolin; 2.04%-3.23% of maleic anhydride; 0.21%-0.38% of 2-(2-hydroxyl-3-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole, and 0.34%-0.43% of zirconium phosphate loaded with silver. The material configuration optimization and deep processing value-added treatment are carried out according to the physicochemical property requirements and use conditions of the pipe, so that the physicochemical property indexes and long-term stability of the pipe are improved, and the material formula cost is reduced.

Owner:JIANGXI TIANFENG CONSTR GRP PLASTIC STEELTECH

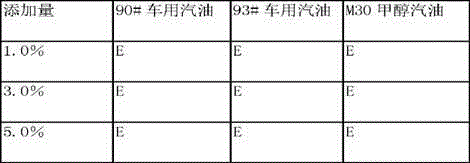

Gasoline additive and preparation method therefor

The invention discloses a gasoline additive and a preparation method therefor. The gasoline additive is prepared from the following raw materials: methyl acetate, ethanol, 3-lauryl thiopropionate, polyacrylamide, hydrogenated castor oil, polyisobutene ethyl carbamate and a catalyst. The raw materials are good in intermiscibility with gasoline, so that the physical and chemical performance indexes of an oil product are comprehensively enhanced, the octane number of gasoline can be remarkably improved, the gasoline additive has an excellent anti-explosive effect, has a good cleaning effect on gasoline, and enables gasoline to fully combust, and therefore, the heat efficiency of fuel oil and the output per liter of an engine is improved.

Owner:吴姣

Clad plate prepared by fusion of at least one composition into compact blending matter and articles manufactured thereby

The invention refers to a kind of composite board and the product made up by melting a kind of composite board into close mixed material, which is made up of modified rosin mixed material and modified asphalt mixed material, thermal plasticity plastic and softening and solidifying mixed material of impacting modifier, the mixed material expresses the character of improved melted thick mixed material. The invention has excellent mechanism intensity and performance in respects of tensile-strength / tensile module, flexing strength / flexing module and shock strength. The invention uses mode of forming and form of extended pressure forming, and forming mode and plastic pouring form method and blowing method to produce composite board and the product, thus the product has diversity and practicability. It uses the secondary energy in energy field. It supports the environment protection in waste processing field.

Owner:刘墨

Preparation method for graphite carbon material

The invention provides a preparation method for a graphite carbon material, wherein, the graphite carbon material is prepared from the following required components in parts by weight:. 99-101 parts of calcined petroleum coke dry material and 20-25 parts of melting asphalt. The preparation method comprises the following steps: (1) mixing and kneading the dry material and an adhesive and then cooling and molding the mixture; (2) calcining for the first time; (3) soaking for the first time; (4) clacining for the second time; (5) soaking for the second time; (6) calcining for the third time; and (7) carrying out a graphitization process. The novel graphite carbon material prepared in accordance with the invention has the advantages of antioxidation, good heat and corrosion resistance, excellent conductivity and good thermal shock resistance, so that the lifetime is as over three times as that of a common graphite anode.

Owner:兴和县鑫源碳素有限公司 +1

Novel application of PTFE (Polytetrafluoroethylene) film to brewing of sweet red yeast rice wine

ActiveCN104262873AExtended shelf lifeFermentation speed controlAlcoholic beverage preparationRed yeast ricePerformance index

The invention relates to a novel application of a high polymer material in the field of fermented foods and particularly relates to a novel application of a PTFE (Polytetrafluoroethylene) film to brewing of a sweet red yeast rice wine. The sweet red yeast rice wine is contained in a fixed-shaped open vessel; an opening part of the vessel is sealed by using a sealing element which is at least ventilated at a local part and can isolate microorganisms in the environment; the sealing element is composed of a bonding part bonded with the wall of the vessel and a functional part with ventilation and isolation functions; and the PTFE film is used for processing the functional part of the sealing element. According to the novel application, the PTFE film is used as a packaging film to be applied to the brewing of the sweet red yeast rice wine, so that the guarantee period of the sweet red yeast rice wine can be greatly prolonged and can be up to 8 months to the maximum extent, the PTFE film plays a role in controlling the fermentation speed of the sweet red yeast rice wine, the sweet red yeast rice wine has no flatulence and rancidity phenomena, and the physical and chemical performance indexes of the sweet red yeast rice wine are good.

Owner:杭州米奥生物科技有限公司

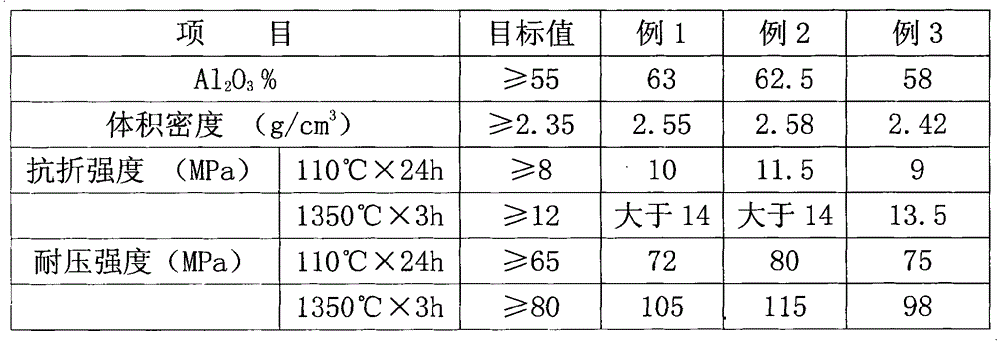

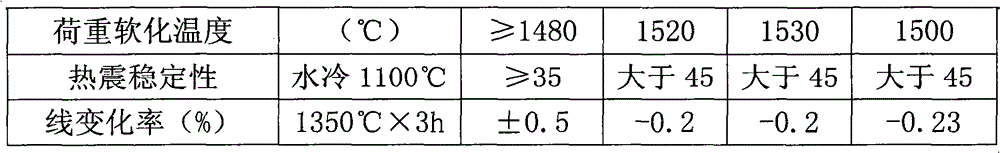

Manufacturing method of seal cover for operation observation aperture on carbon calciner fire wall

ActiveCN102276263BImproved thermal shock stabilityExcellent softening temperature under loadFiberFlexural strength

The invention provides a manufacturing method of a seal cover for an operation observation aperture on a carbon calciner fire wall. Raw materials consist of three parts of aggregate, matrix and additive. The aggregate comprises three or more components selected from: granular mullite, high aluminium corundum, bauxite chamotte, flint clay and andalusite; the matrix comprises fine-powdered mullite,bauxite chamotte, andalusite or kyanite or sillimanite, alumina, high-alumina cement, silicon micro powder and high temperature heat resistant steel fiber; the additive is a mixture comprising two ormore components selected from sodium tripolyphosphate, sodium hexametaphosphate, CMC, FDN and sodium lignosulfonate. The manufacturing method includes steps of: proportioning raw materials; mixing bya mixer; adding water with stirring; putting into a die; partitioning into blocks and moulding; carrying out natural maintenance; and drying at 110 DEG C-300 DEG C for 24-48h. The invention has beneficial effect that the seal cover produced by the method has excellent physical and chemical performance indexes, such as high high-temperature flexural strength, good thermal shock stability and refractoiness under load.

Owner:河南鑫诚耐火材料股份有限公司

Micro-electrolysis water generator

InactiveCN102050507BImprove physical and chemical performance indicatorsWater/sewage treatmentStationary filtering element filtersElectrolysisPollution

The invention provides a micro-electrolysis water generator, which is matched with a water dispenser or is used independently, and can generate drinking water which is beneficial to human bodies, such as alkaline electrolysis water. In the micro-electrolysis water generator, the water dispenser is convenient to clean, and the secondary pollution of the water dispenser is prevented. The micro-electrolysis water generator comprises a smart seat component, a water inlet component, a water outlet component, a filter element component and a floater component, wherein the water inlet cavity is formed on the middle part of the smart seat component; the water inlet component is fixed on the middle part at the bottom end of the smart seat component and is positioned in the water inlet cavity, and the water inlet component is provided with a water inlet; the filter element component is positioned below the smart seat component; the outlet of the water inlet component is communicated with the water outlet component; the water outlet of the water outlet component is communicated with the filter element component; the filter element component comprises a middle part through hole; a filter element is positioned on the periphery of the middle part through hole; the water outlet component is positioned in the middle part through hole of the filter element component; and the top of the floater component is fixed in an inner cavity of the water outlet component, and the floater component comprises a floater positioned below the filter element component.

Owner:珠海天睿生物科技有限公司

Plastic composite board composition preparation method

The invention relates to a halogen-free flame-retardant dynamic vulcanized ternary ethylene-propylene rubber / polypropylene thermoplastic elastomer, which comprises EPT rubber, polypropylene (PP), cross linking agent, non-halogen flame-proof architecture, plasticizing agent and auxiliary agent, wherein the non-halogen flame-proof architecture employs magnesium hydroxide / red phosphorus system, and the halogen-free flame-retardant ternary ethylene-propylene rubber / polypropylene thermoplastic elastomer is obtained through extrusion machine dynamic vulcanization extrusion granulating. The thermoplastic elastomer can be widely applied into the fields of automobile, architecture and cables where halogen-free flame resistance is needed.

Owner:刘墨

Additive for producing biologic diesel oil directly from grease of animals and plants, and biologic diesel oil prepared by the additive

InactiveCN101050376BImprove physical and chemical performance indicatorsHigh calorific valueBiofuelsLiquid hydrocarbon mixture productionOil and greaseBiodiesel

This invention discloses an additive for producing biosiesel oil from animal and plant oils. The additive is prepared from: dimethyl carbonate 35-45 wt.%, KOH 10-15 wt.%, catalyst 0.75-1.25 wt.%, saponification inhibitor 8.25-13.75 wt.%, chain-breaking agent 6-10 wt.%, and ethylene glycol monomethyl ether 30-40 wt.%. The obtained biodiesel oil comprises animal and plant oils, diesel oil and additive at a weight ratio of (30-60) :( 38-65) :( 2-5).

Owner:曹志德

Dyed melamine glue impregnated surface layer paper decoration artificial plate production process

InactiveCN110696443AHigh bonding strengthHigh strengthLaminationLamination apparatusEngineeringPulp and paper industry

The invention discloses a dyed melamine glue impregnated surface layer paper decoration artificial plate production process, which comprises: adhering natural wood skin on the surface of an artificialplate by using common melamine glue impregnated surface layer paper, the natural wood skin and a super-flat steel template through a heat-conducting heating pressing technology; carrying out primarycoarse sanding and primary fine sanding on the artificial plate adhered with the natural wood skin, and cleaning; and adhering dyed surface layer paper to the surface of the wood skin by using dyed melamine glue impregnated surface layer paper and a ultra-flat or wood thorn convex surface steel template through a heat-conducting heating pressing technology. According to the invention, the productcan replace the existing natural wood skin decoration plate material, the cost and the construction difficulty are reduced, and the production operation effect, the industrial production, and the physical quality standard of the product are improved.

Owner:天湘(江苏)新材料科技有限公司

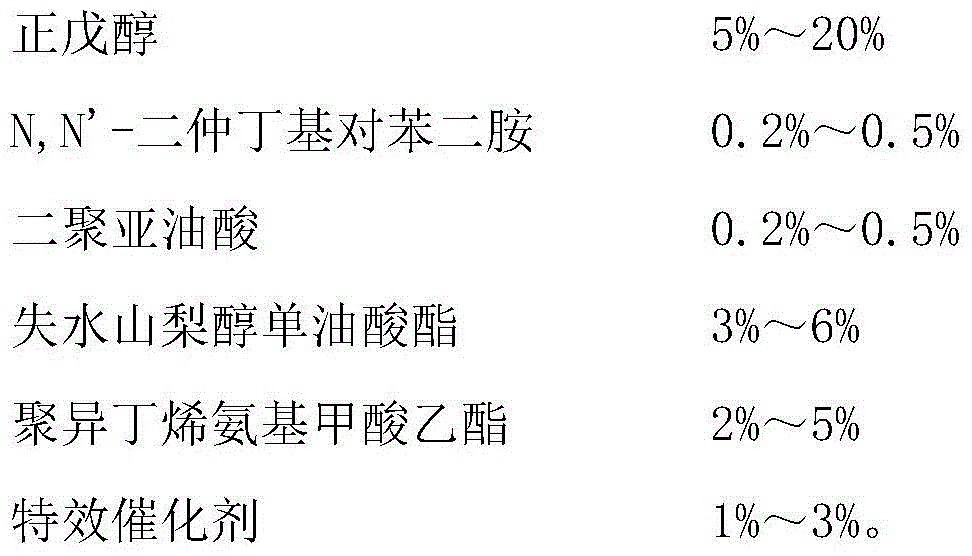

A kind of high cleaning gasoline additive and preparation method thereof

The invention discloses a high-clean gasoline additive and a preparation method thereof, which are prepared from the following raw materials in weight percent: DMC, n-pentanol, N,N'-di-sec-butyl-p-phenylenediamine, benzotriazole, Sorbitan monooleate, polyisobutylene urethane and special-effect catalyst, the raw materials of which contain oxygen-rich and multi-effect ingredients, have good compatibility with gasoline, and comprehensively improve the physical and chemical performance indicators of oil products; this product can significantly Improve the octane number of gasoline and have excellent anti-knock effect, have a good cleaning effect on gasoline and make it fully combustible, thereby improving the thermal efficiency of fuel and the power per liter of the engine; this product significantly reduces the harmful gas emitted by the tail gas, Environmental pollution is reduced.

Owner:杨长江

A kind of preparation method of polyalkenyl succinimide ashless dispersant

ActiveCN104326962BLow reaction temperatureShort reaction timeOrganic chemistryPolyolefinReaction temperature

Owner:江西福安路润滑材料有限公司

Preparation method of microbial soil conditioner

InactiveCN109503270AIncrease profitImprove defectsBioloigcal waste fertilisersOrganic fertiliser preparationSodium BentoniteOrganic farming

The invention relates to the technical field of agriculture, in particular to a preparation method of a microbial soil conditioner. The microbial soil conditioner comprises the following raw materials: agricultural organic wastes, an inorganic fertilizer, chitosan, rice husk powder, traditional Chinese medicine residues and gleditsia sinensis. The microbial soil conditioner is prepared by the abandoned organic agricultural wastes, so that the wastes can be changed into valuables, the utilization rate of resources is increased, and the defect that a traditional soil conditioner uses bentonite is overcome, therefore, the soil conditioner is higher in decomposition speed.

Owner:重庆天泽兴环境科技有限公司

Additive for producing high-grade gasoline using 90# gasoline and the high grade gasoline

InactiveCN1318551CImprove physical and chemical performance indicatorsIncrease the calorific value of combustionLiquid carbonaceous fuelsCyclohexanoneGasoline

Disclosed is an additive for producing high-grade gasoline using 90# gasoline and the high grade gasoline comprising raw materials of the following constituents (by weight proportion): nitrobenzene 35-45%, cyclohexanone 10-15%, propanone 15-25%, mono methoxy polyethylene 30-40%. The weight ratio of 90# gasoline, methanol and additive is 60-81:18-38:1-2.

Owner:曹志德

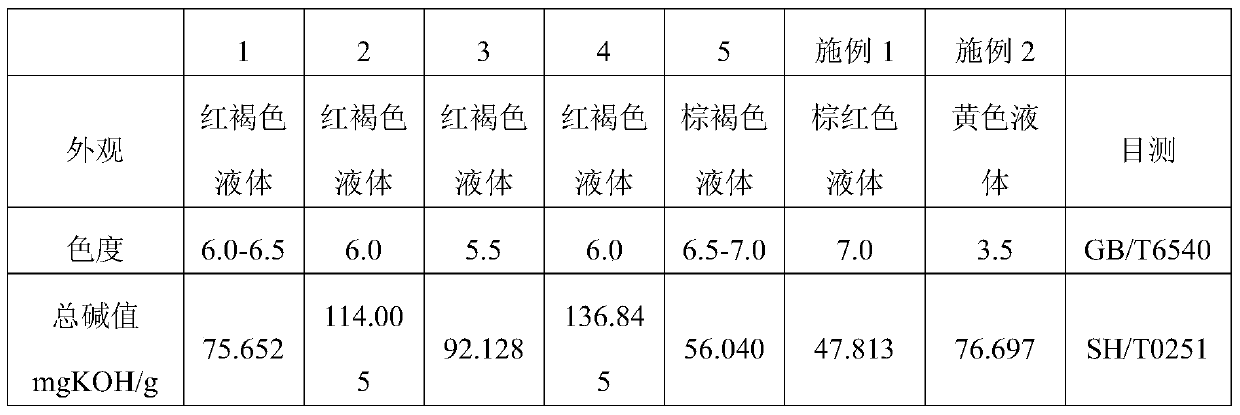

Chlorine gas metering and leading-in device in phenylethene thermostable resin chloridization process

ActiveCN100457793CStable continuous additionImprove physical and chemical performance indicatorsFeed devicesMeasuring instrumentPhysical chemistry

The invention relates to an introduction device for chlorine measurement, belonging to accurate measuring addition device. It is characterized in that it comprises chlorine bottle, continous measuring scale for chlorine bottle, chloride outlet valve, chlorine pipe, chlorine measuring device, chlorine adjusting valve and chlorine distributorp; chlorine bottle is set on said continous measuring device, one end of chlorine pipe is connected with chlorine bottle and connected with chlorine outlet valve, chlorine measuring instrument, chlorine adjusting valve in sequence; the other end is equipped with chlorine distributor that inserts into chlorination reaction kettle. The device enables chlorine to be fed into chlorination reaction kettle continuously, safely and quantitatively, makes the chlorination easy to realize and chlorine content in resin can be controlled accurately. The device can be widely used in phenylethylene high temperature-resistance resin chlorination process.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com