Anti-entangling and anti-damage rubber covered roller formula for spinning production and rubber compound preparation process thereof

An anti-damage and cot technology, applied in the field of textile processing, can solve the problems of poor swelling and anti-winding stability, poor oil resistance and wear resistance, fast decay of yarn quality, etc., and achieve resistance to the swelling of spinning processing aids - oil agents , Reduce the peeling oily wear, eliminate the effect of winding and broken ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The anti-winding and anti-damage rubber roller formula for spinning production provided in this example, the raw materials are weighed according to the proportions by weight shown in Table 1, and the finished rubber roller can be obtained after the mixed rubber is formed and processed. .

[0026] Table 1

[0027] components Example A Example B Example C Carboxylated Hydrogenated Nitrile Rubber 60 50 40 Nitrile rubber 40 50 60 Zinc oxide 5 5 5 Titanium dioxide 10 10 10 NBC 1.5 1.5 1.5 SR517 4 3.5 3 SN 0.5 0.5 0.5 E-XCB 2 1.5 1 TP-90B 14 12 8 Molybdenum disulfide 2 1.5 1 RL-22 1 1 0.5 Silica 6 8 12 FRD-980W 1.8 1.5 1.2

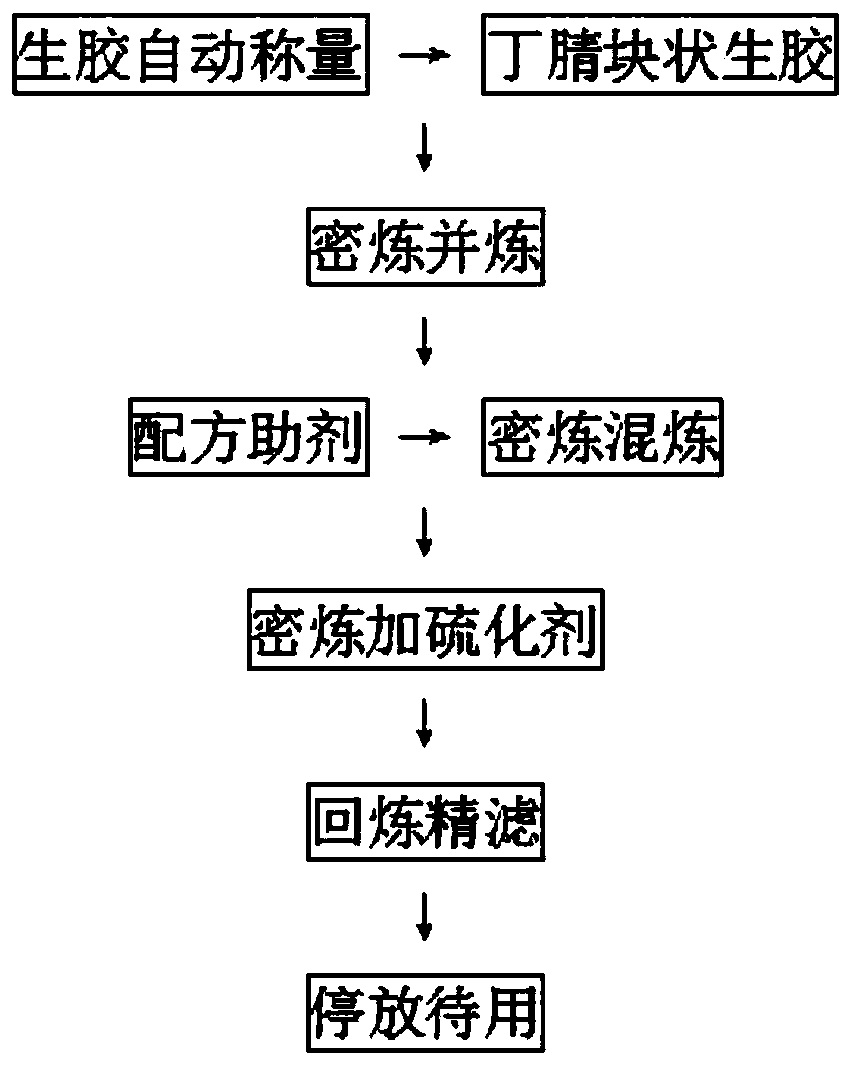

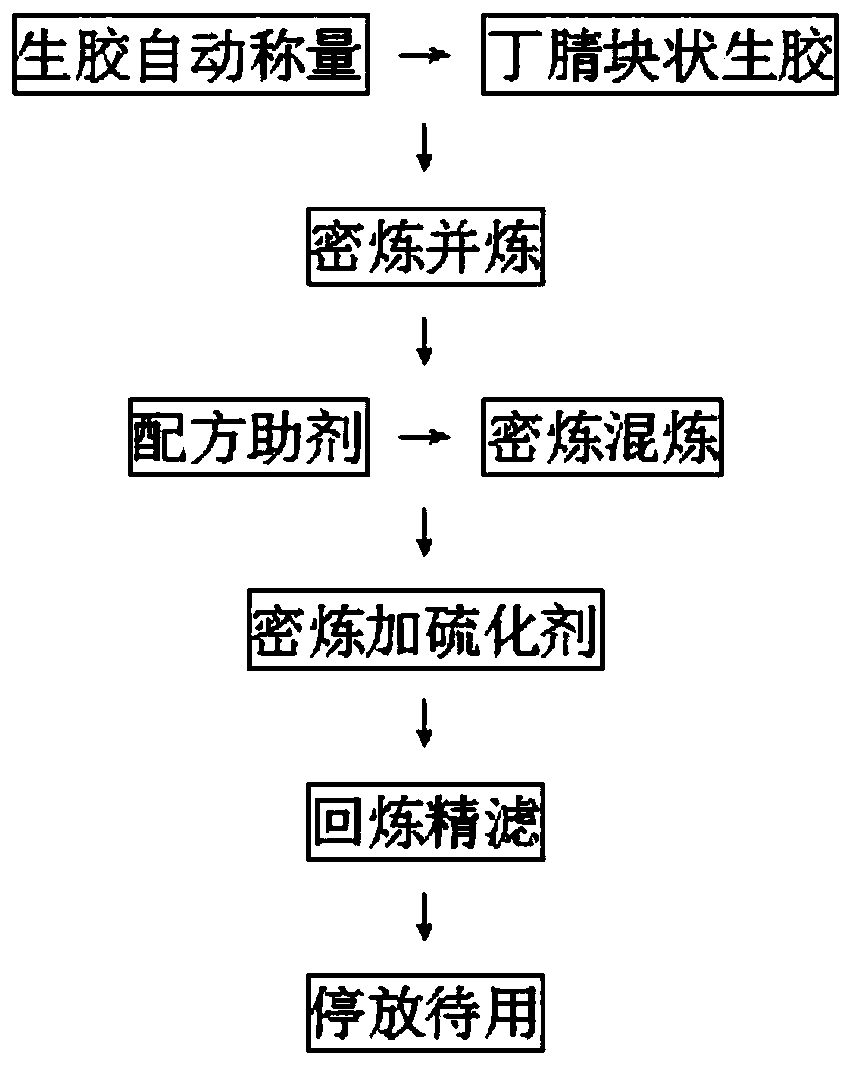

[0028] Preparation methods such as figure 1 As shown, the specific steps are:

[0029] 1) Ingredients: Carboxylated hydrogenated nitrile rubber, nitrile rubber, zinc oxide, titanium dioxide, anti-aging agent, accelerator, antistati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com