Production process of isostatic pressing special graphite

A technology of special graphite and production process, which is applied in the field of graphite production to achieve the effect of improving yield, physical and chemical performance indicators, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

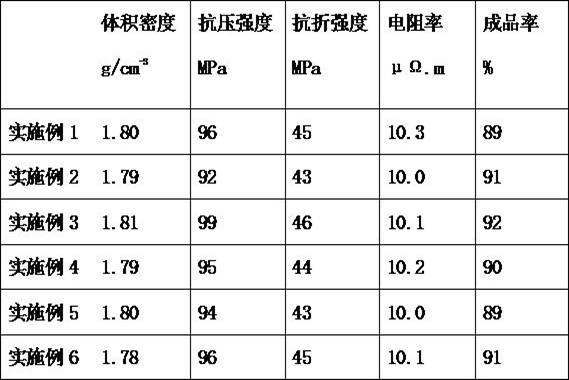

Examples

Embodiment 1

[0034] A production process of isostatic pressing special graphite, comprising the following steps:

[0035] (1) Crushing and primary grinding: the calcined coke, pitch coke, and modified pitch are first crushed with a crusher to a size below 10mm, and then crushed with a pulverizer to a particle size of 10-20 microns.

[0036] (2) Kneading and cooling: Add the pulverized calcined coke, pitch coke and modified pitch into the kneader at a weight ratio of 30:37:33. The kneader is heated with heat transfer oil, and the temperature of the heat transfer oil is 200°C. After 4 hours of kneading, the paste was lowered into a cooler for stirring and cooling.

[0037] (3) Secondary crushing, secondary grinding, and screening: Put the cooled paste into the crusher for coarse crushing to a particle size below 10mm, then use a mill to crush it to a particle size of 15-30 microns, and then crush the crushed The material is screened with a 60-mesh screening machine.

[0038] (4) Isostatic ...

Embodiment 2

[0044] A production process of isostatic pressing special graphite, comprising the following steps:

[0045] (1) Crushing and primary grinding: the calcined coke, pitch coke, and modified pitch are first crushed with a crusher to a size below 10mm, and then crushed with a pulverizer to a particle size of 10-20 microns.

[0046] (2) Kneading and cooling: Add the pulverized calcined coke, pitch coke and modified pitch into the kneader at a weight ratio of 30:35:35. The kneader is heated with heat transfer oil, and the temperature of the heat transfer oil is 200°C. After 5 hours of kneading, the paste was lowered into a cooler for stirring and cooling.

[0047] (3) Secondary crushing, secondary grinding, and screening: Put the cooled paste into the crusher for coarse crushing to a particle size below 10mm, then use a mill to crush it to a particle size of 15-30 microns, and then crush the crushed The material is screened with a 60-mesh screening machine.

[0048] (4) Isostatic ...

Embodiment 3

[0054] A production process of isostatic pressing special graphite, comprising the following steps:

[0055] (1) Crushing and primary grinding: the calcined coke, pitch coke, and modified pitch are first crushed with a crusher to a size below 10mm, and then crushed with a pulverizer to a particle size of 10-20 microns.

[0056] (2) Kneading and cooling: Add the pulverized calcined coke, pitch coke and modified pitch into the kneader at a weight ratio of 30:38:32, and heat the kneader with heat transfer oil at a temperature of 200°C. After 5 hours of kneading, the paste was lowered into a cooler for stirring and cooling.

[0057] (3) Secondary crushing, secondary grinding, and screening: Put the cooled paste into the crusher for coarse crushing to a particle size below 10mm, then use a mill to crush it to a particle size of 15-30 microns, and then crush the crushed The material is screened with an 80-mesh screening machine.

[0058] (4) Isostatic pressing: Put the screened ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com