Method for preparing prebaked anode by using aluminum electrolysis waste carbon cathode

A pre-baked anode and aluminum electrolysis technology is applied in the field of aluminum electrolysis waste carbon cathode recycling, which can solve the problems of increasing process difficulty, increasing preparation cost, and failing to form industrialized applications, and achieves reduction of anode production cost and physical and chemical performance indicators. The effect of lifting, increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the examples.

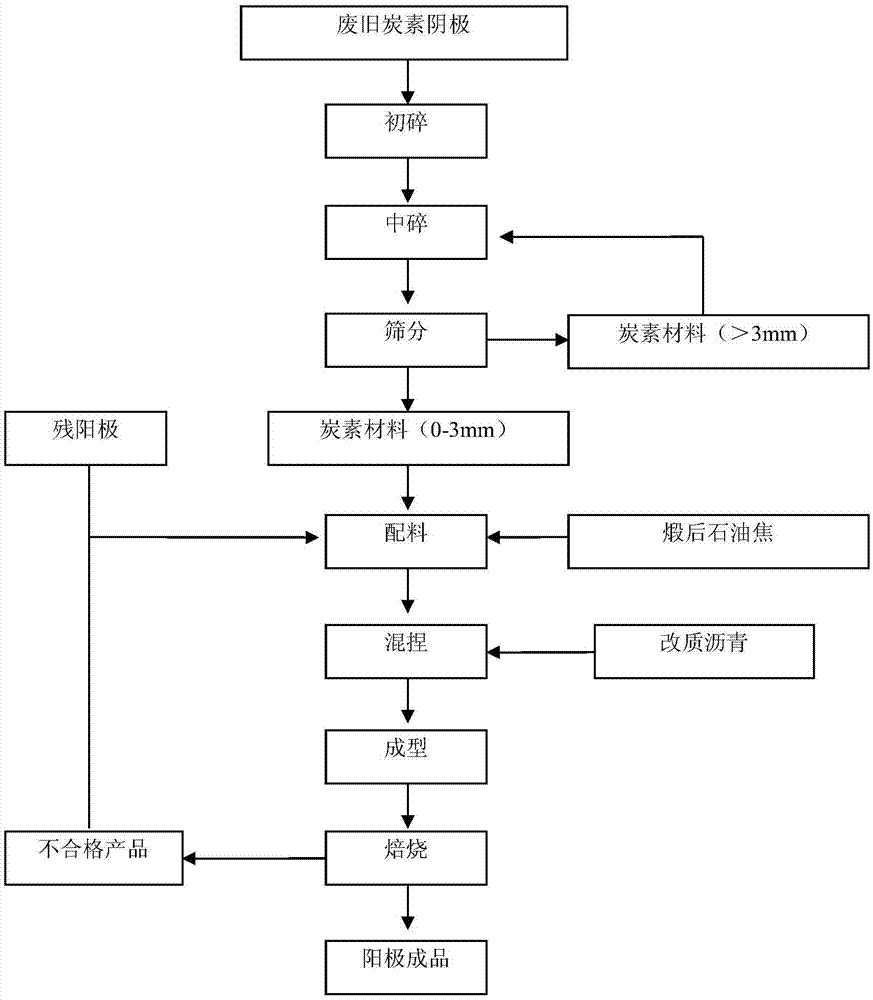

[0019] A method for preparing a prebaked anode by using the waste carbon cathode of aluminum electrolysis, the steps of the method are as follows:

[0020] (1) Separating the lining carbon material, refractory material and steel rod of the waste carbon cathode of aluminum electrolysis, cleaning the aluminum electrolyte and other impurities on the surface of the carbon material, and coarsely crushing the carbon material with a crusher;

[0021] (2) Transport the coarsely crushed carbon material with a particle size of less than 70mm to the silo. After the material is discharged from the silo, it is transported to the electromagnetic iron remover by the electromagnetic vibrating feeder and belt conveyor for electromagnetic iron removal, and then the impact crusher is used. Carry out intermediate crushing, after intermediate crushing, it is sent to the vibrating screen by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com