Preparation method of LFP (lithium ferric phosphate) electrode material

An electrode material, lithium iron phosphate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of contact area and sintering reaction limit, complicated process and equipment, long production cycle and other problems, so as to facilitate the production process and The control and adjustment of product quality, the improvement of physical and chemical performance indicators, and the improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

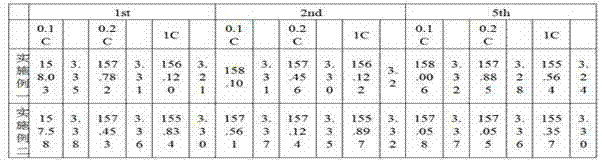

Embodiment 1

[0026] A closed furnace is used. The furnace is lined with fused corundum bricks or covered with platinum skin on the surface of the refractory material. The temperature in the furnace is above 1538°C. The heating method of the furnace is direct combustion heating. The heat source of the furnace is combustible gas or The liquid is burned and heated; the atmosphere in the furnace chamber is controlled near neutral. Adopt the mode of continuous feeding to put into raw material, the mass composition of raw material is: 15.8%Li 2 CO 3 , 32.5%Fe 2 o 3 , 51.7%NH 4 h 2 PO 4 . When the melt flows out of the furnace, water quenching is carried out immediately, and the section from the melt outlet to the water quenching is as airtight as possible and protected by nitrogen gas. Drying after water quenching, and then ultrafine powder processing with an ultrafine mill, the particle size D50 after ultrafine grinding is 1 micron. Then carbon coating is carried out, and the organic ca...

Embodiment 2

[0028] A closed furnace is used, the furnace is lined with fused corundum bricks or covered with platinum skin on the surface of the refractory material, the temperature in the furnace is above 1538°C, the heating method is direct flame heating or flame heating, and the heat source is electric heating, Combustible gas or liquid combustion heating. The atmosphere in the hearth of the furnace is controlled near neutral. Adopt the mode of intermittent feeding to drop into raw material, the mass composition of raw material is: 16% Li 2 CO 3 , 29.8%Fe 2 o 3 , 52.5%NH 4 h 2 PO 4 , 1.7%TiO 2 . When the melt flows out of the furnace, water quenching is carried out immediately, and the area between the melt outlet and the water quenching area is sealed and protected by nitrogen gas. Drying after water quenching, and then ultrafine powder processing with an ultrafine mill, the particle size D50 after ultrafine pulverization is 9 microns. Then carbon coating is carried out, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com