Manufacturing method of seal cover for operation observation aperture on carbon calciner fire wall

A manufacturing method and operation hole technology are applied in the field of manufacturing a sealing cover for an observation operation hole of a fire channel wall of a carbon roaster, and can solve the problems of general physical and chemical performance indicators such as load softening temperature, poor thermal shock stability, and low high temperature flexural strength. and other problems, to achieve the effects of excellent physical and chemical performance indicators, good thermal shock stability, and high high temperature flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

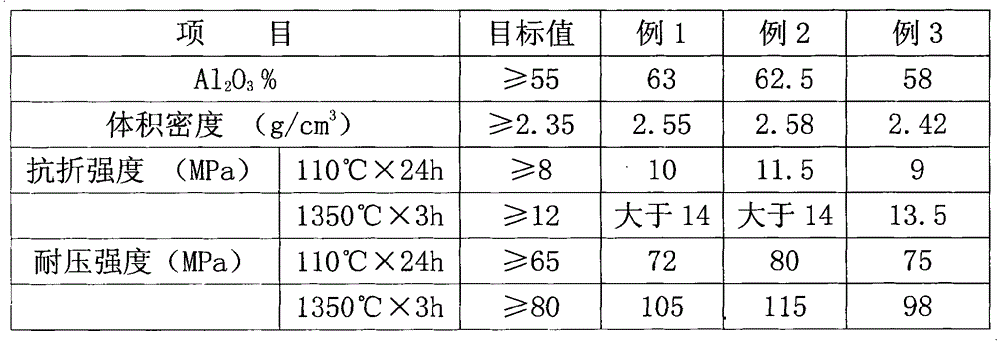

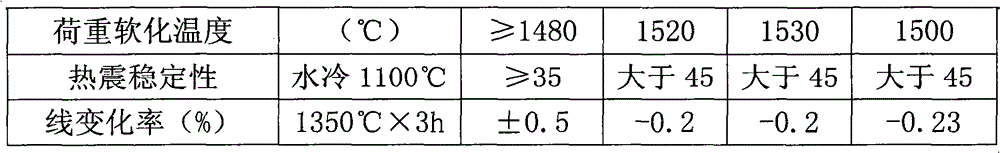

Examples

Embodiment 1

[0031] Embodiment 1: choose the raw material component of following parts by weight:

[0032] Mullite particles (AL 2 o 3 55~70%), 65,

[0033] High alumina bauxite clinker particles (AL2O3 50-60%), 10,

[0034] Andalusite particles (AL2O3 50-65%), 10,

[0035] The particle diameters of the above-mentioned particles are all 0-8mm,

[0036] Mullite fine powder (AL 2 o 3 55~70%), 10,

[0037] High alumina bauxite clinker fine powder (AL2O3 50-60%), 5,

[0038] Sillimanite fine powder (AL 2 o 3 50~60%), 5,

[0039] The mesh numbers of the above fine powders are all 180 mesh,

[0040] Alumina powder (AL 2 o 3 ≥98%) 300 mesh, 3,

[0041] High alumina cement fine powder (AL 2 o 3 ≥70%) 200 mesh, 5,

[0042] Silica powder (SiO2≥90%) 300 mesh, 4,

[0043] High-temperature heat-resistant steel fiber (length 5-50mm), 2,

[0044] Sodium tripolyphosphate, 0.1,

[0045] Sodium hexametaphosphate, 0.15,

[0046] After mixing in parts by weight, add it to the mixer and...

Embodiment 2

[0047] Embodiment 2: choose the raw material component of following parts by weight:

[0048] Mullite particles (AL 2 o 3 55~70%), 10,

[0049] Burnt gemstone particles (AL2O 350~60%), 30,

[0050] High alumina corundum particles (AL2O3 50-65%), 65,

[0051] The particle diameters of the above-mentioned particles are all 0-8mm,

[0052] Mullite fine powder (AL 2 o 3 55~70%), 5,

[0053] High alumina bauxite clinker fine powder (AL2O3 50-60%), 8,

[0054] Kyanite fine powder (AL 2 o 3 50~60%), 5,

[0055] The mesh numbers of the above fine powders are all 180 mesh,

[0056] Alumina powder (AL 2 o 3 ≥98%) 300 mesh, 8,

[0057] High alumina cement fine powder (AL 2 o 3 ≥70%) 200 mesh, 10,

[0058] Silica powder (SiO2≥90%) 300 mesh, 5,

[0059] High temperature heat-resistant steel fiber (length 5 ~ 50mm), 1.5,

[0060]Sodium tripolyphosphate, 0.2,

[0061] FDN, 0.15,

[0062] After mixing according to the weight parts, add it to the mixer and mix it with w...

Embodiment 3

[0063] Embodiment 3: choose the raw material component of following parts by weight:

[0064] Mullite particles (AL 2 o 3 55~70%), 25,

[0065] High alumina bauxite clinker particles (AL2O3 50-60%), 65,

[0066] Andalusite particles (AL 2 o 3 50~65%), 5,

[0067] The particle diameters of the above-mentioned particles are all 0-8mm,

[0068] Mullite fine powder (AL 2 o 3 55~70%), 7,

[0069] High alumina bauxite clinker fine powder (AL2O3 50-60%), 6,

[0070] Andalusite fine powder (AL 2 o 3 50~60%), 3,

[0071] The mesh numbers of the above fine powders are all 180 mesh,

[0072] Alumina fine powder (AL 2 o 3 ≥98%) 300 mesh, 8,

[0073] High alumina cement fine powder (AL 2 o 3 ≥70%) 200 mesh, 12,

[0074] Silica powder (SiO2≥90%) 300 mesh, 6,

[0075] High temperature heat-resistant steel fiber (length 5 ~ 50mm), 1.5,

[0076] Sodium tripolyphosphate, 0.2,

[0077] CMC, 0.1,

[0078] After mixing according to the weight parts, add it to the mixer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com