Hydraulic locking mechanism

A locking mechanism and hydraulic technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problem of low reliability of hydraulic circuit locking, and achieve the effects of simple structure, easy manufacture and flexible response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] detailed description: The present invention will be further described below in conjunction with accompanying drawing:

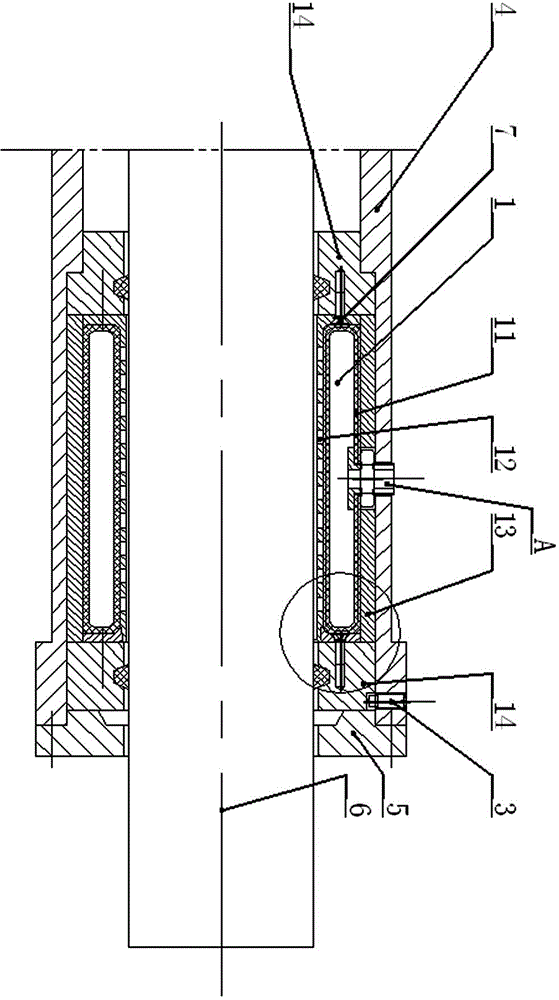

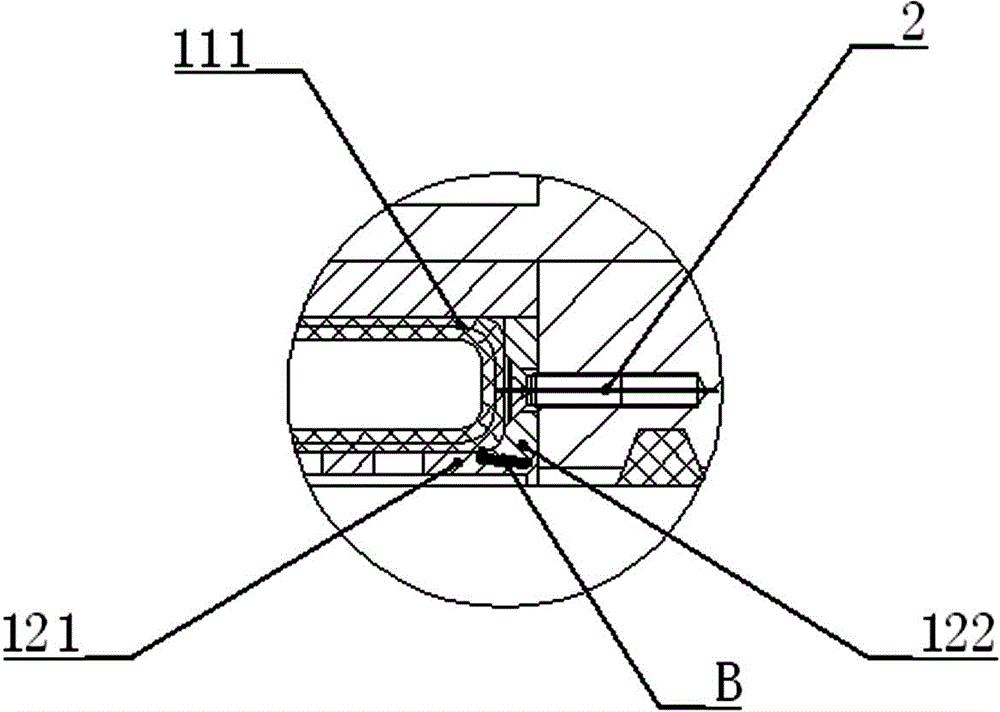

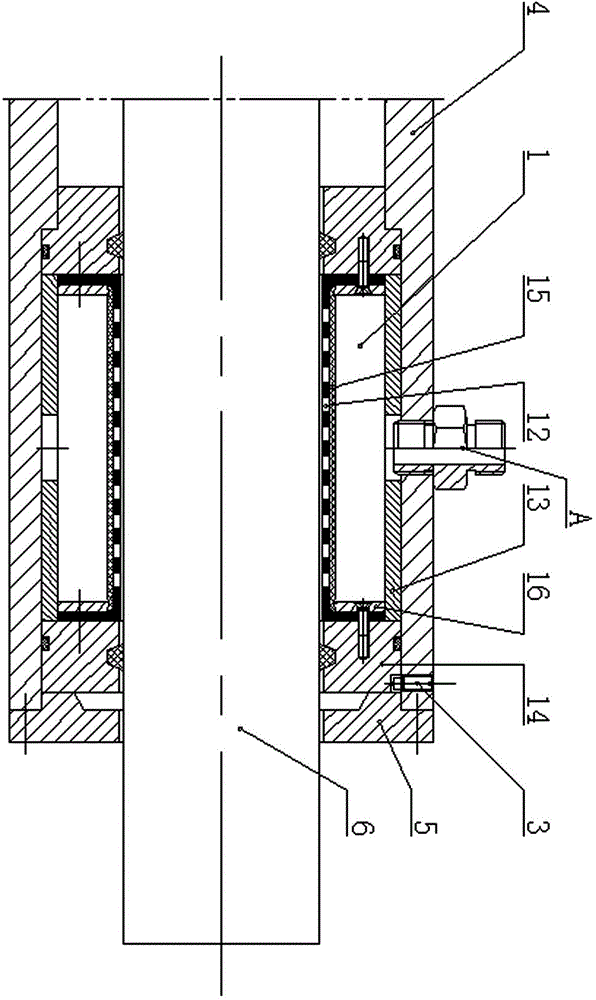

[0030] Such as figure 1 As shown, the present invention provides a kind of hydraulic locking mechanism, and this hydraulic locking mechanism comprises: Mechanism cylinder body 4, flange end cover 5, hydraulic cylinder piston rod 6, hydraulic oil bag 11, locking mesh cover 12, axial Support sleeve 13 and net cover support ring 14; Locking net cover 12 and net cover support ring 14 are sleeved on the piston rod 6, and there is a gap between the elastically deformable locking net cover 12 and the piston rod 6. Satisfied conditions are: when the locking net sleeve 12 undergoes elastic deformation, the locking net sleeve 12 can hold the piston rod 6 tightly; Lock the outer side of the net sleeve 12 and make contact with the net sleeve 12. The axial support sleeve 13 is installed on the outer side of the oil bag 11, and the outer side of the axial suppor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap