A kind of rubber adhesive and preparation method thereof

A rubber adhesive and liquid rubber technology, applied in the direction of adhesives, rubber derivatives, adhesive types, etc., can solve the problems of easily polluting the battery, poor washing performance, and insufficient adhesion, and achieve easy construction and excellent resistance. Good effect of sagging and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

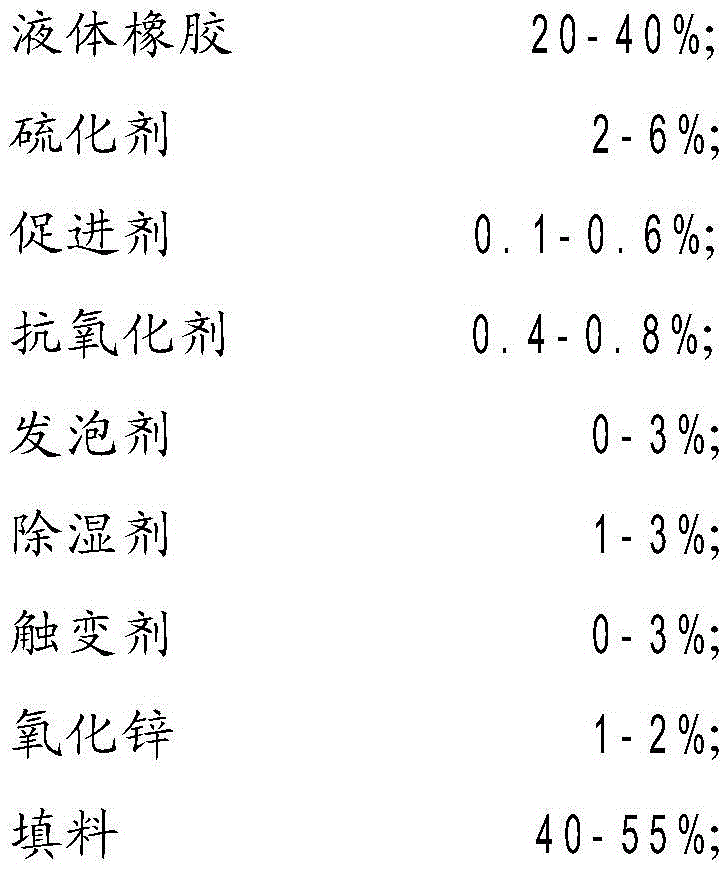

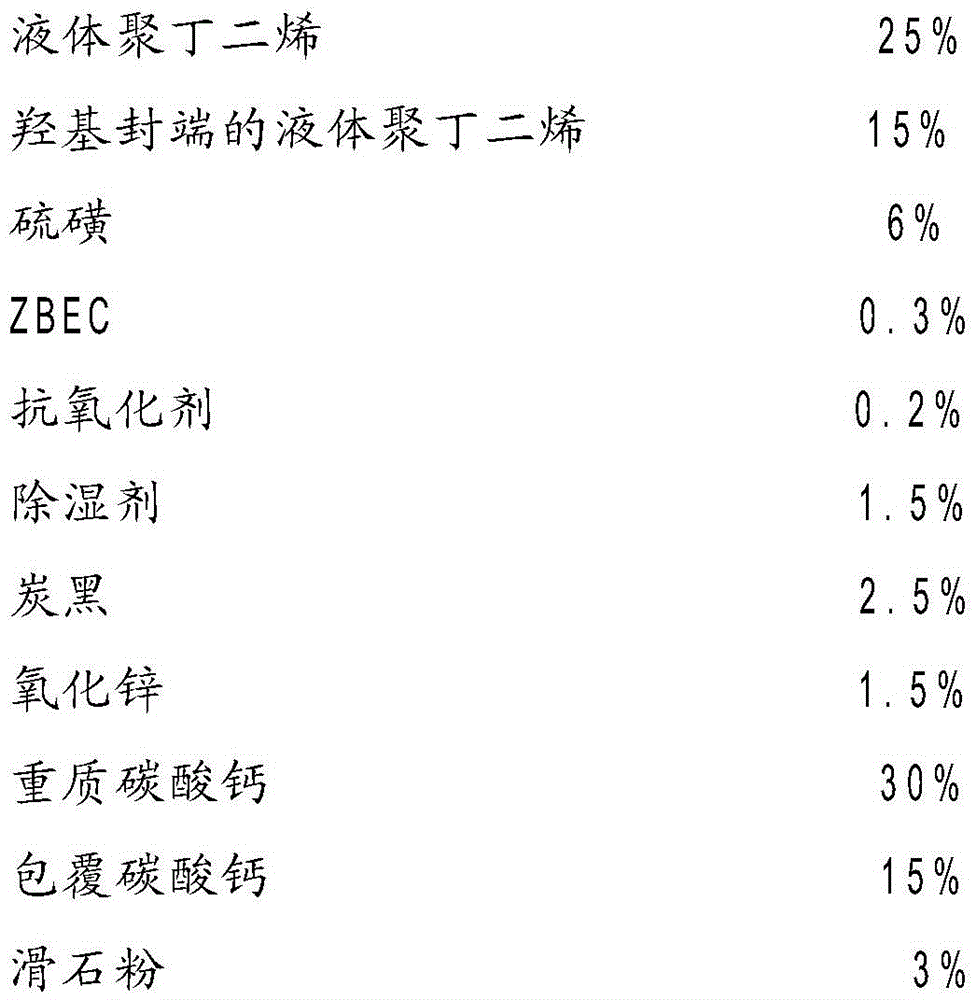

[0035] A kind of rubber adhesive, by weight percentage, this rubber adhesive is made up of following components:

[0036]

[0037] The preparation method of above-mentioned rubber adhesive, its step is:

[0038] (1) First add liquid rubber to the reaction kettle, and the liquid rubber is obtained by mixing liquid polybutadiene and hydroxyl-terminated liquid polybutadiene evenly;

[0039] (2) Add sulfur, accelerator ZBEC, antioxidant, desiccant, carbon black and zinc oxide in sequence to the liquid rubber obtained in step (1), and stir in vacuum for 10 minutes;

[0040] (3) Open the reactor, add heavy calcium carbonate to the mixture obtained in the above step (2), stir in vacuum for 10 minutes, then open the reactor, add coated calcium carbonate and talcum powder into the reactor, and stir in vacuum for 10 minutes;

[0041] (4) Open the reactor, scrape off the mixture obtained in the above step (3) attached to the wall of the reactor, and stir it in vacuum for 20-30 minute...

Embodiment 2

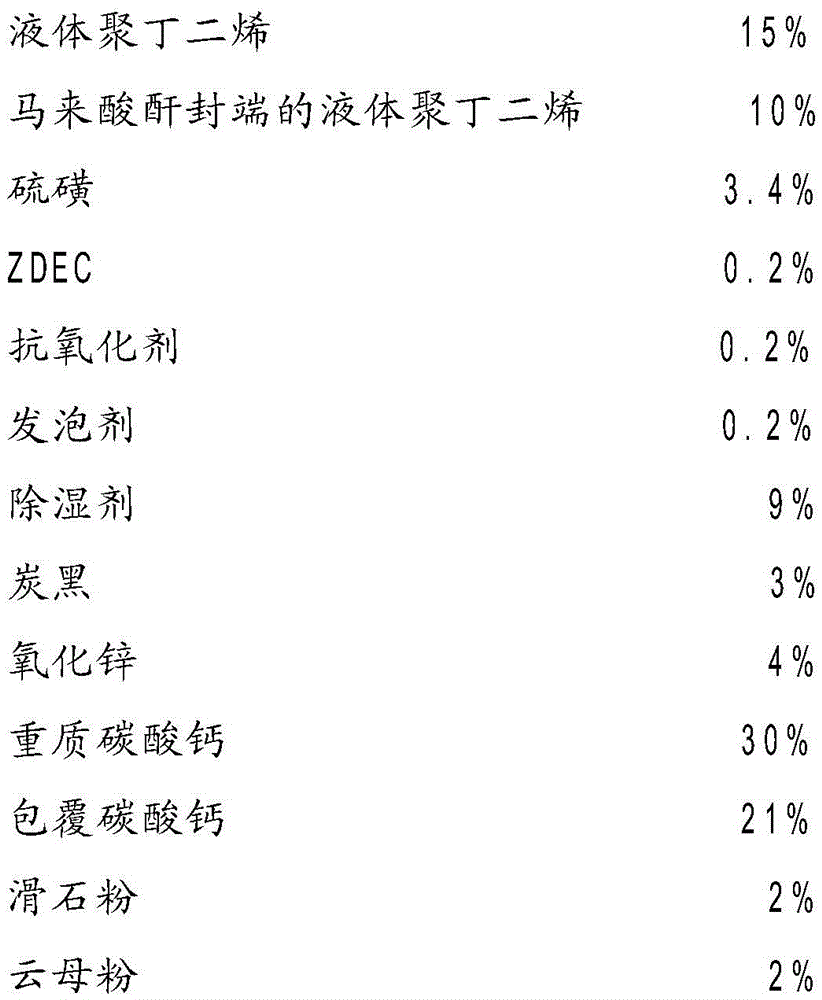

[0048] A kind of rubber adhesive, by weight percentage, this rubber adhesive is made up of following components:

[0049]

[0050] The preparation method of above-mentioned rubber adhesive, its step is:

[0051] (1) First add liquid rubber into the reaction kettle, and the liquid rubber is obtained by mixing liquid polybutadiene and maleic anhydride-capped liquid polybutadiene evenly;

[0052] (2) Add sulfur, accelerator ZDEC, antioxidant, foaming agent, desiccant, carbon black and zinc oxide in sequence to the liquid rubber obtained in step (1), and stir in vacuum for 10 minutes;

[0053] (3) Open the reactor, add heavy calcium carbonate to the mixture obtained in the above step (2), stir in vacuum for 10 minutes, then open the reactor, add coated calcium carbonate, talcum powder and mica powder into the reactor, vacuum Stir for 10 minutes;

[0054] (4) Open the reactor, scrape off the mixture obtained in the above step (3) attached to the wall of the reactor, and stir i...

Embodiment 3

[0061] A kind of rubber adhesive, by weight percentage, this rubber adhesive is made up of following components:

[0062]

[0063] The preparation method of above-mentioned rubber adhesive, its step is:

[0064] (1) First add liquid rubber into the reaction kettle, and the liquid rubber is obtained by mixing liquid polybutadiene and epoxy-terminated liquid polybutadiene evenly;

[0065] (2) Add sulfur, accelerator ZBEC, antioxidant, dehumidifier, carbon black and zinc oxide in sequence to the liquid rubber obtained in step (1), and stir in vacuum for 10 minutes;

[0066] (3) Open the reactor, add heavy calcium carbonate to the mixture obtained in the above step (2), stir in vacuum for 10 minutes, then open the reactor, add coated calcium carbonate and mica powder into the reactor, and stir in vacuum for 10 minutes;

[0067] (4) Open the reactor, scrape off the mixture obtained in the above step (3) attached to the wall of the reactor, and stir it in vacuum for 20-30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com