Lubricating-grease automatic filling device for bearing

An automatic filling and grease technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve the problems affecting natural gas export production tasks, uncertainty of the operating frequency of the guide wheel, deflection of the guide wheel, etc., to ensure Relative continuity and uniformity, ensuring proper lubrication, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

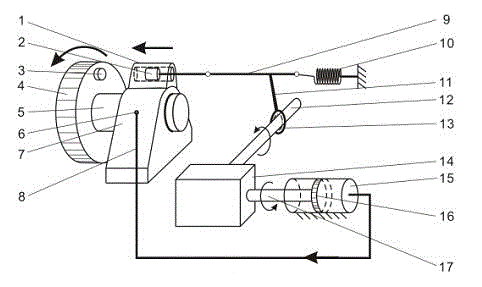

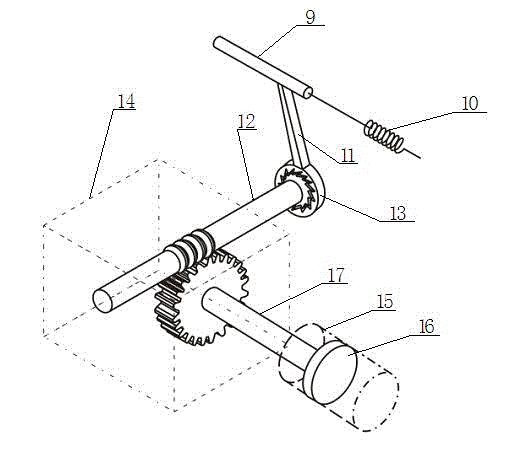

[0017] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0018] The present invention comprises a transmission mechanism, a deceleration mechanism and a grease filling mechanism, and is characterized in that the transmission mechanism comprises a guide wheel 4, a strong magnet 3 arranged on the inner surface of the guide wheel, and the end arranged on the guide wheel bearing frame 7 is opposite to the strong magnet The magnetic cylinder 1, the cylindrical magnetic core 2 located in the magnetic cylinder, the connecting rod 9 connected with the magnetic core, the coil spring 10 connected with the end of the connecting rod and fixed on the bracket, the belt swing rod connected with the outer circumference of the connecting rod The ratchet 13 of 11; The deceleration mechanism comprises reduction box 14, is provided with the input shaft 12 of line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com