Machine vision LED (light emitting diode) illumination source

A technology of LED lighting and machine vision, applied in the field of machine vision LED lighting sources, can solve the problems of difficult control of reflected light of objects, non-adjustable light, unevenness, etc., and achieve rich brightness, incident angle, uniform light, and uniform lighting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

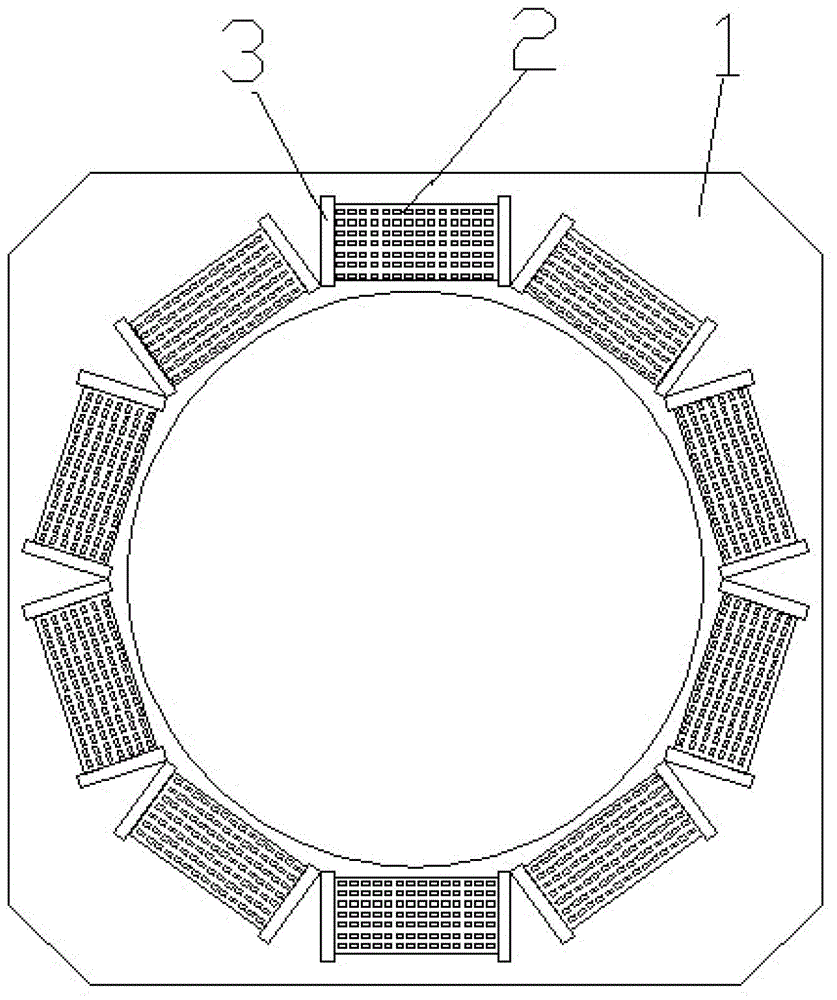

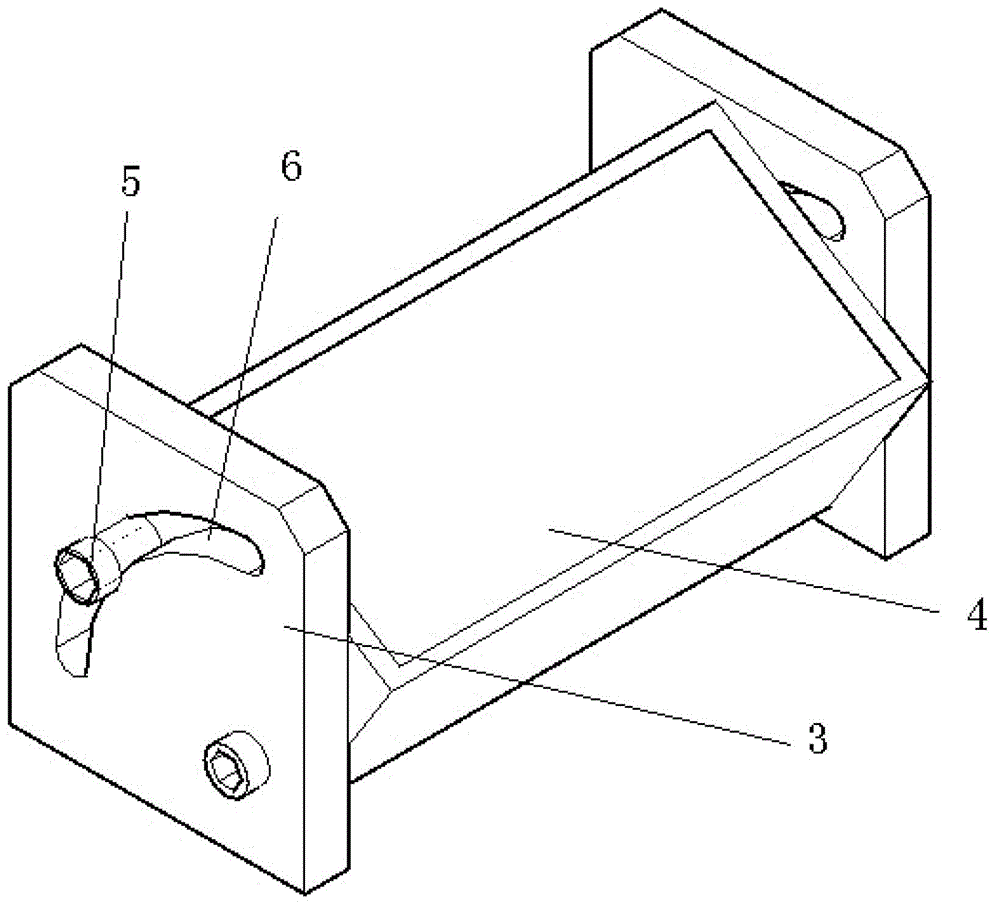

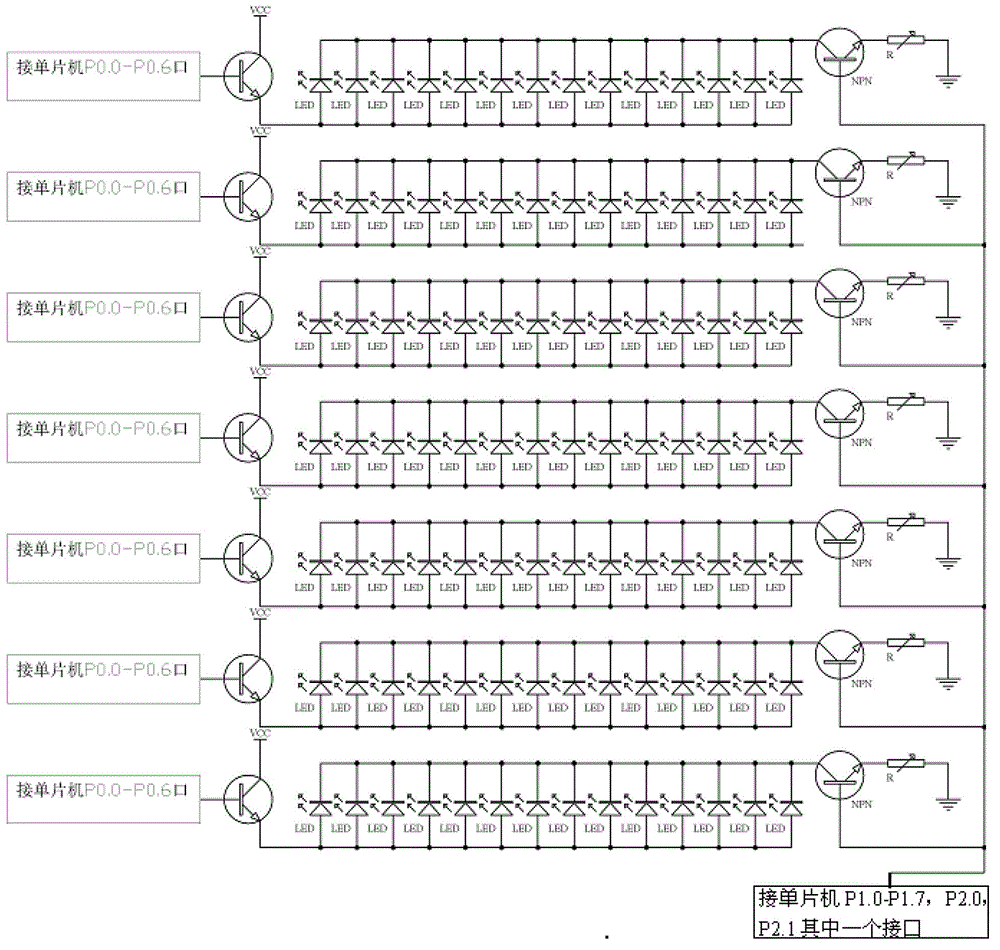

[0018] Such as figure 1 , 2 As shown, the machine vision LED lighting source of the present invention includes a bottom controller (not shown in the figure), a seat 1, and a matrix light source assembly installed on the base 1. The matrix light source assembly includes two brackets 3 and is movably installed on LED matrix light source 2 between two brackets 3 . Arc-shaped chute 6 is respectively arranged on two brackets 3, and slide bar 5 is set on both sides of LED matrix light source 2 corresponding to the position of arc-shaped chute 6, and slide bar 5 is placed in arc-shaped chute 6, and slide bar 5 Slidingly connected with arc chute 6. The number of said matrix light source components is 10, and they are installed on the base 1 in an equidecagonal shape. The controller is connected with the LED matrix light source 2 .

[0019] Arc-shaped chute 6 is respectively arranged on two brackets 3, and slide bar 5 is set on both sides of LED matrix light source 2 corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com