Design and adjusting method for fuel oil metering device starting flow characteristics

A technology of starting flow and metering device, which is applied in the direction of measuring device, volume/mass flow generated by mechanical effects, relative volume flow measurement, etc., and can solve the problem that the fuel metering device has no effective starting flow characteristic design and adjustment method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

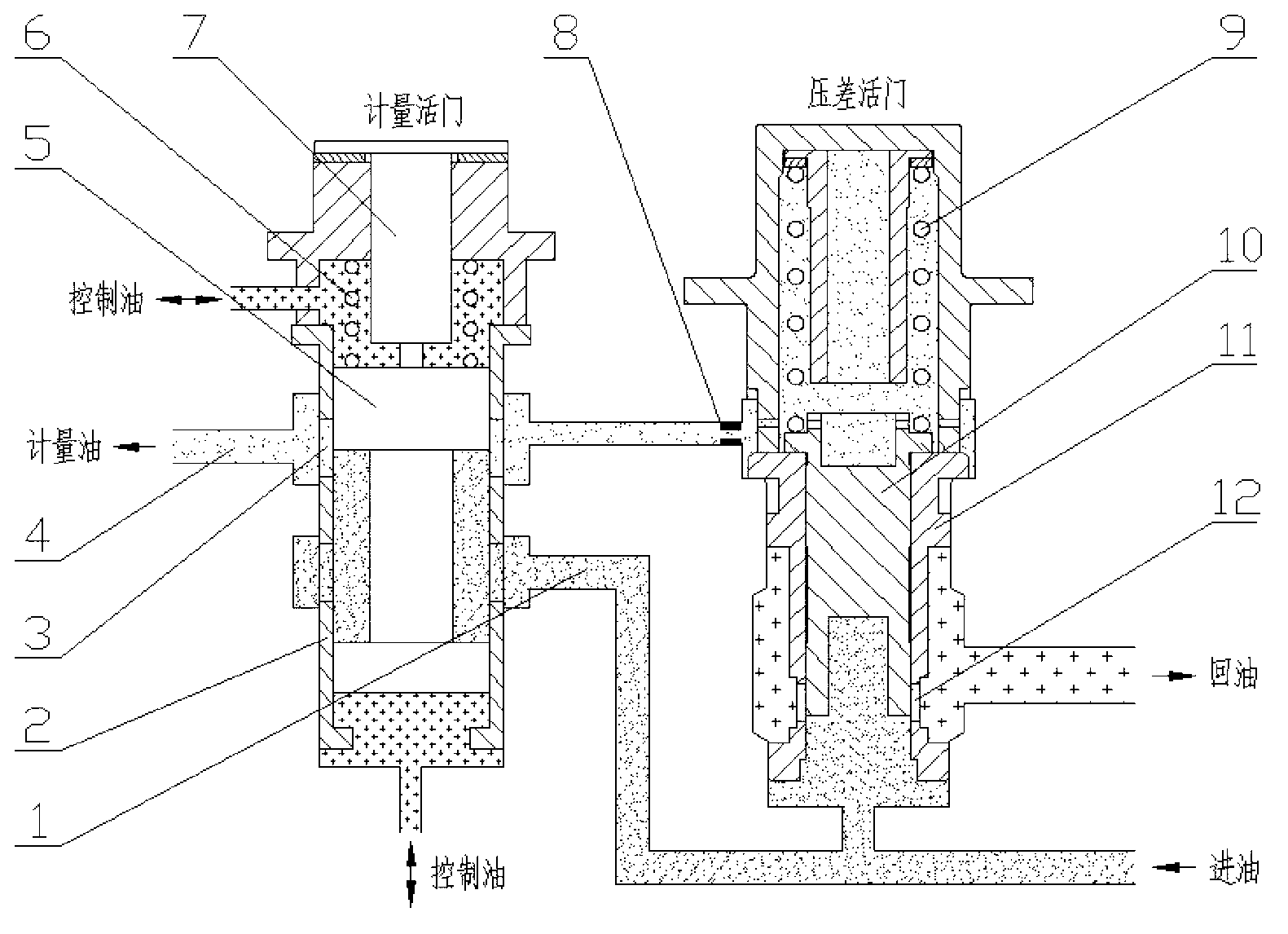

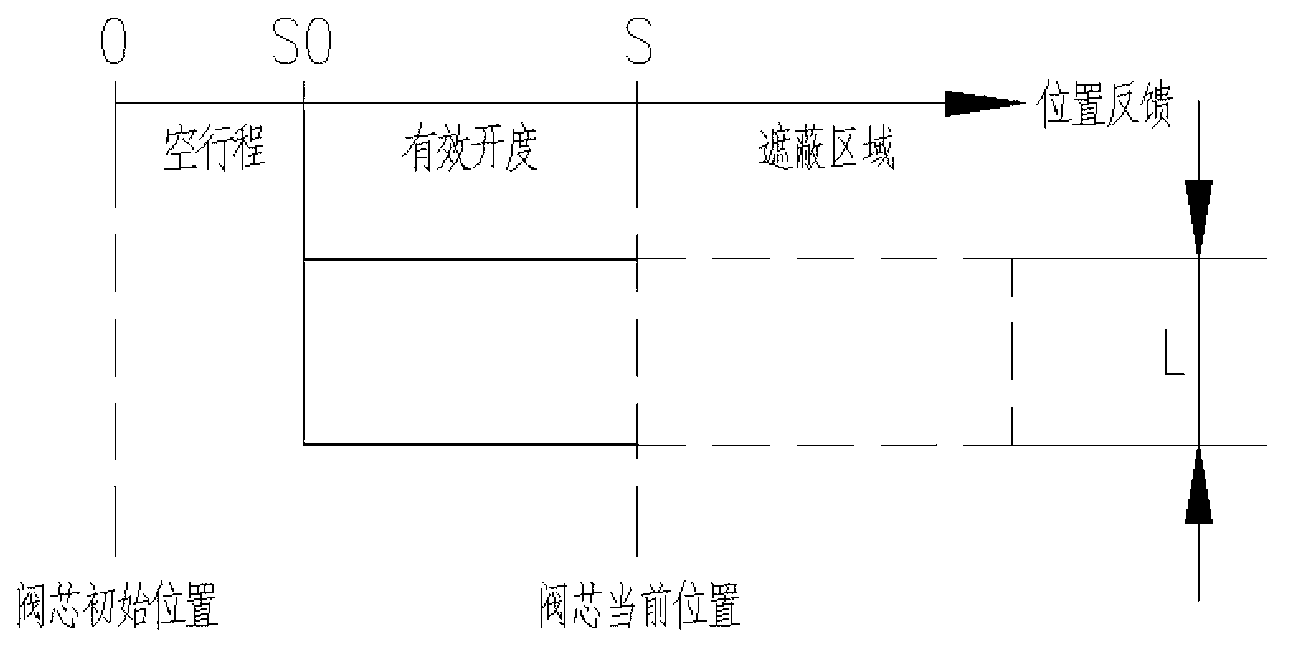

[0060] This embodiment provides a fuel metering device starting flow characteristic design and adjustment method, characterized in that: the fuel metering device starting flow characteristic design and adjustment method is divided into the following 6 steps:

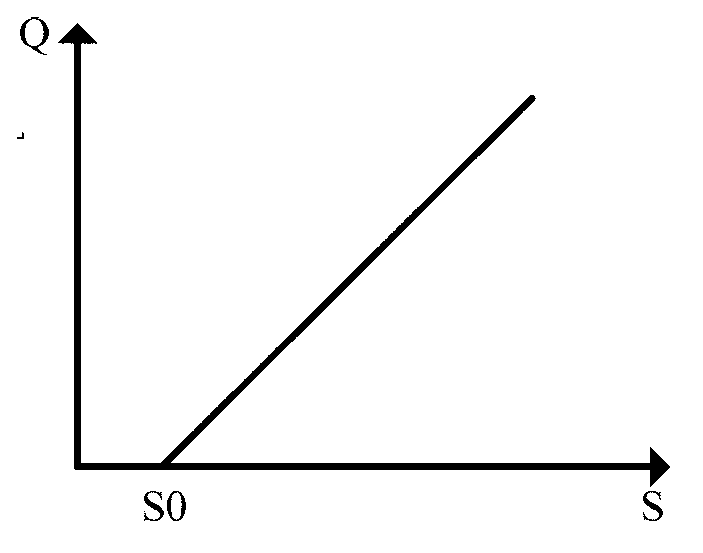

[0061] 1) The fuel metering device adopts a fuel flow metering method with a constant pressure difference, and the metering valve adopts or partly adopts a rectangular fuel control window to make the starting flow characteristic linear;

[0062] 2) Set up a bypass adjustment element with adjustable flow area in parallel with the metering valve, so that the intercept of the starting flow characteristic can be adjusted;

[0063] 3) As a standard part of fuel metering device, its pressure difference valve or pressure difference return valve pressure difference, metering valve spool initial position feedback value, metering valve fuel control window width, bypass adjustment element flow area and other parameters should be within the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com