Preventive maintenance turnover mechanism

A flipping mechanism and front maintenance technology, applied in optics, instruments, projection devices, etc., can solve the problems of unrealizable, heavy quality, etc., and achieve the effect of ensuring reliability and stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be further explained below by specific examples.

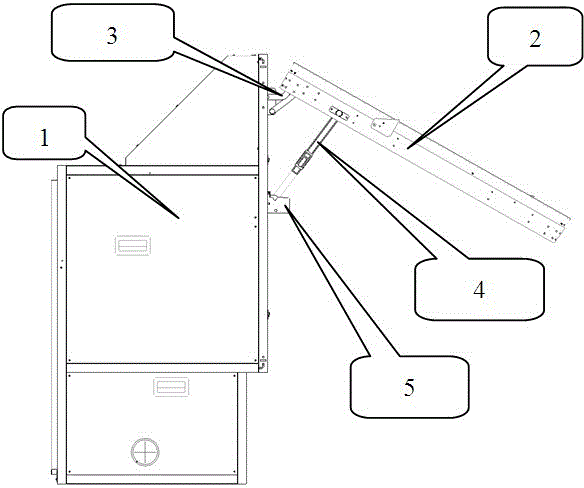

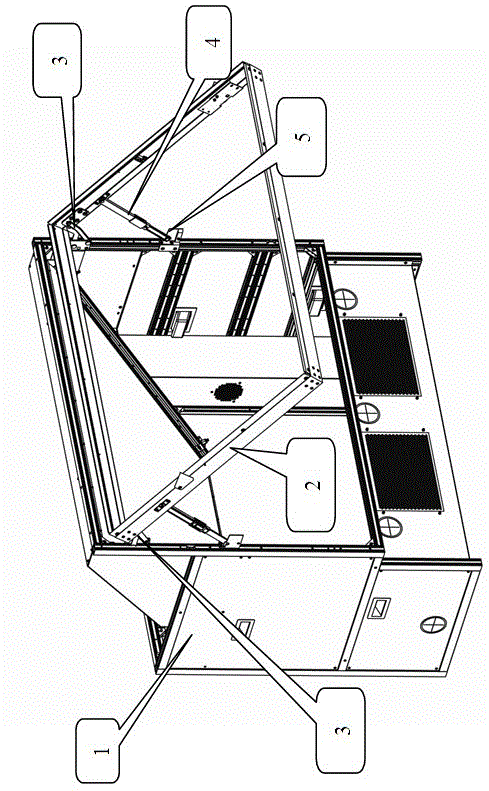

[0027] Such as figure 1 , 2 As shown, a front maintenance turnover mechanism includes a box body 1, a screen assembly 2, a four-bar mechanism hinge 3, a free positioning type sliding brace 4 and an adjustment mechanism 5, and the upper end of the screen assembly 2 is hinged on the On the upper end of the box body 1, free positioning sliding stays 4 are set on both sides of the screen assembly 2 for supporting and positioning the screen assembly 2, and the adjustment mechanism 5 is set on both sides of the box body 1 for fine adjustment of the screen assembly 2 .

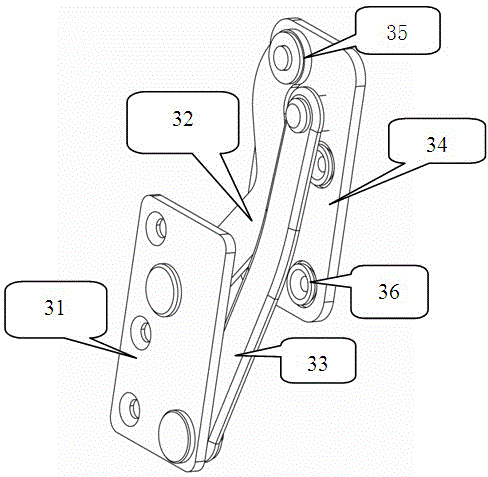

[0028] Such as image 3 As shown, the four-bar mechanism hinge 3 includes a hinge mechanism fixing plate 31, a first hinge mechanism bracket 32, a second hinge mechanism bracket 33, a hinge rotating plate 34, a hinge pin 35 and a collar 36,

[0029] Described four-bar mechanism hinge 3 is installed on the box body 1 by hinge mechanism fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com