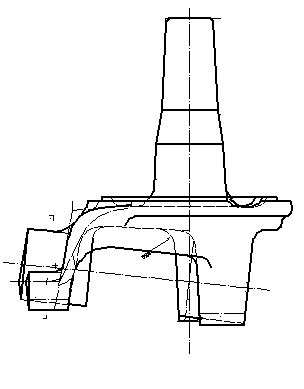

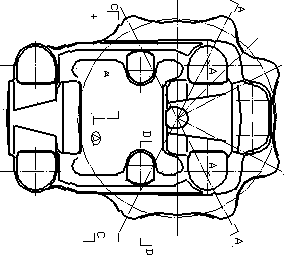

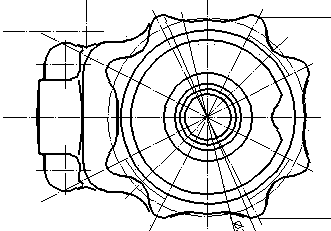

Forging process of heavy truck steering knuckle

A steering knuckle and process technology, applied to railway car body parts, transportation and packaging, vehicle parts, etc., can solve problems such as unstable quality, difficult parameters, and difficult mass production, so as to achieve controllable process parameters, improve production efficiency, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is as follows: the present invention adopts the method for closed extrusion,

[0026] The analysis of the specific forging process is as follows: the longest dimension of the product in the longitudinal direction: 347.5mm; the longest dimension of the product in the width direction: 230mm; the longest dimension of the product in the height direction: 309mm; the weight of the containing body: 263 Kg; the weight of the forging: 31.5 kg; S= 0.12 It belongs to S4 level complex forgings, and the prominent problem reflected in it is the problem of too long rod.

[0027] According to the above problems to develop a specific process:

[0028] 1. Formulation of rough drawings

[0029] Focus on solving the forming problem of the rod part, but it cannot be consistent with the terminal size. It is designed according to the principle that the weight cannot be changed, and the missing weight of the rod part is transferred to the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com