Bolt gasket assembling device

A technology for assembling devices and bolts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of complicated structure, time-consuming and labor-intensive, etc., and achieve the effect of simple structure, reduced labor cost and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

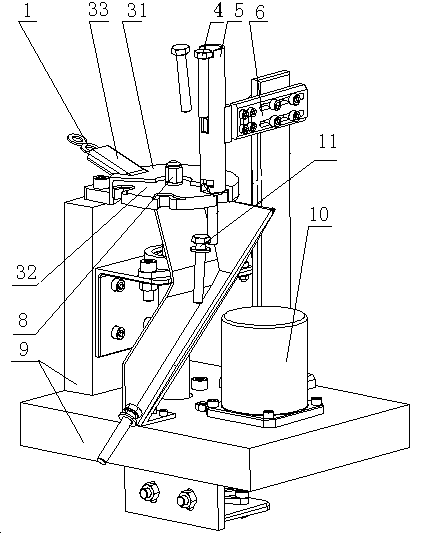

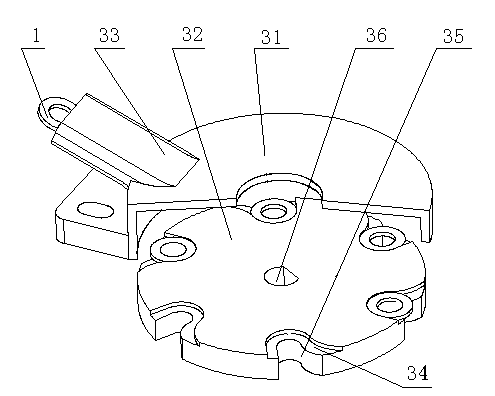

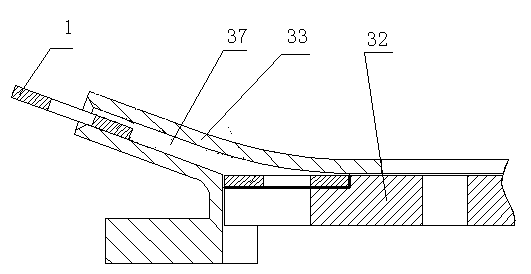

[0020] Such as figure 1 , figure 2 and image 3 As shown, the bolt gasket assembly device of the present invention includes a gasket distribution plate, a bolt conduit 5, an intermittent rotation mechanism and a bracket 9, and the gasket distribution plate includes a cover plate 31 and a distribution plate 32, and the cover plate 31 is located at the Above the distribution plate 32, the cover plate 31 is provided with an oblique protrusion 33, and the oblique protrusion 33 is provided with a gasket guide groove 37, and the cover plate 31 is integrally fixed on the support 9; The edge of the distribution plate 32 is provided with a half-open spacer groove 34, and the center of the half-open spacer groove 34 is provided with a through hole 35 that allows the rod of the bolt to be assembled to pass through smoothly; the bolt guide 5 Located directly above the half-open gasket groove 34, the distribution plate 32 designs the size of the gasket guide groove 37 and the half-open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com