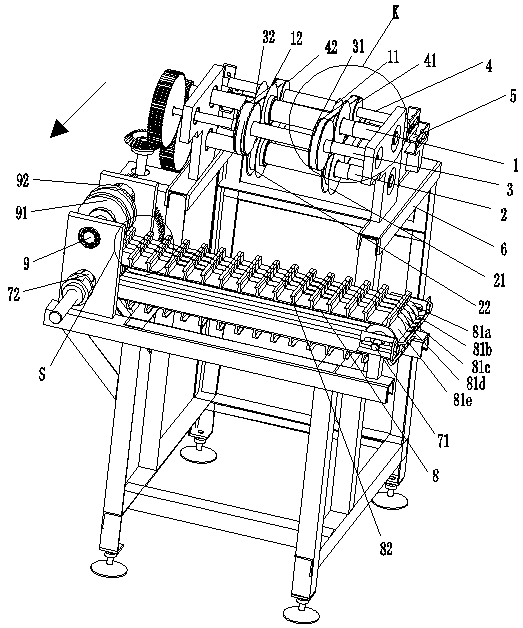

Chicken claw cutting machine

A cutting machine and cutting mechanism technology, applied in metal processing and other directions, to achieve the effect of low failure rate and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

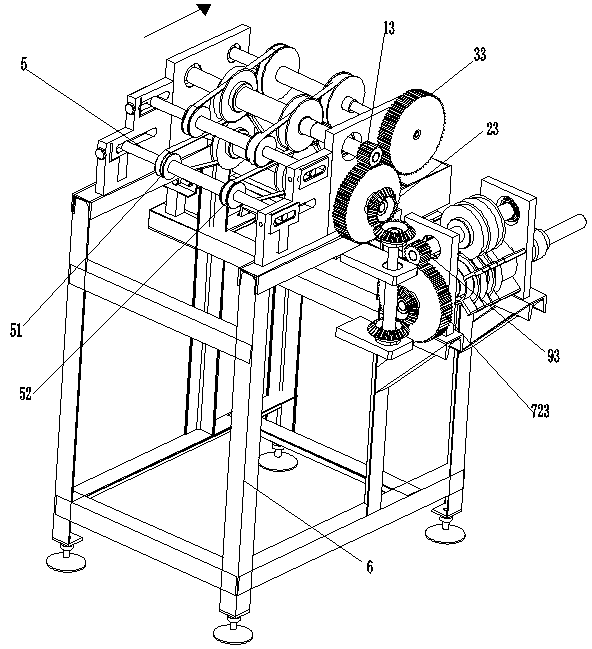

Embodiment 2

[0044] Embodiment two: see Figure 5 , Embodiment 1 can be improved as follows, that is, two chutes are arranged obliquely at the first cutting device, that is, the first chute a (ie Figure 5 middle right chute), the second chute b (ie Figure 5 The chute on the left side of the center), the upper end of the chute is used as the entrance, and the lower end is the exit. The entrance of the first chute a is connected to the exit of the cutting mechanism formed by the cooperation of the first upper cutter wheel 11 and the first lower cutter wheel 21. The entrance of the second chute b is connected to the exit of the cutting mechanism formed by the cooperation of the second upper cutter wheel 12 and the second lower cutter wheel 22 .

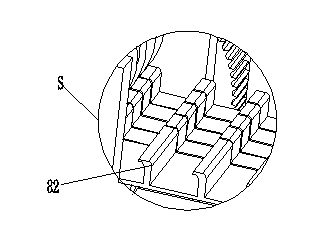

[0045] Furthermore, the main bone claw conveyor belt 8 is sleeved on the rotating shafts I, II 71, 73 respectively, see Figure 5 , that is, the rotating shaft II 73 is arranged parallel to the left side of the fourth cutter shaft 72. In order fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com