Rack-type speed-multiplying secondary ejecting device

A secondary ejector and rack-type technology, which is applied in the field of rack-type double-speed secondary ejector devices, can solve the problems of low efficiency, low efficiency, and application limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

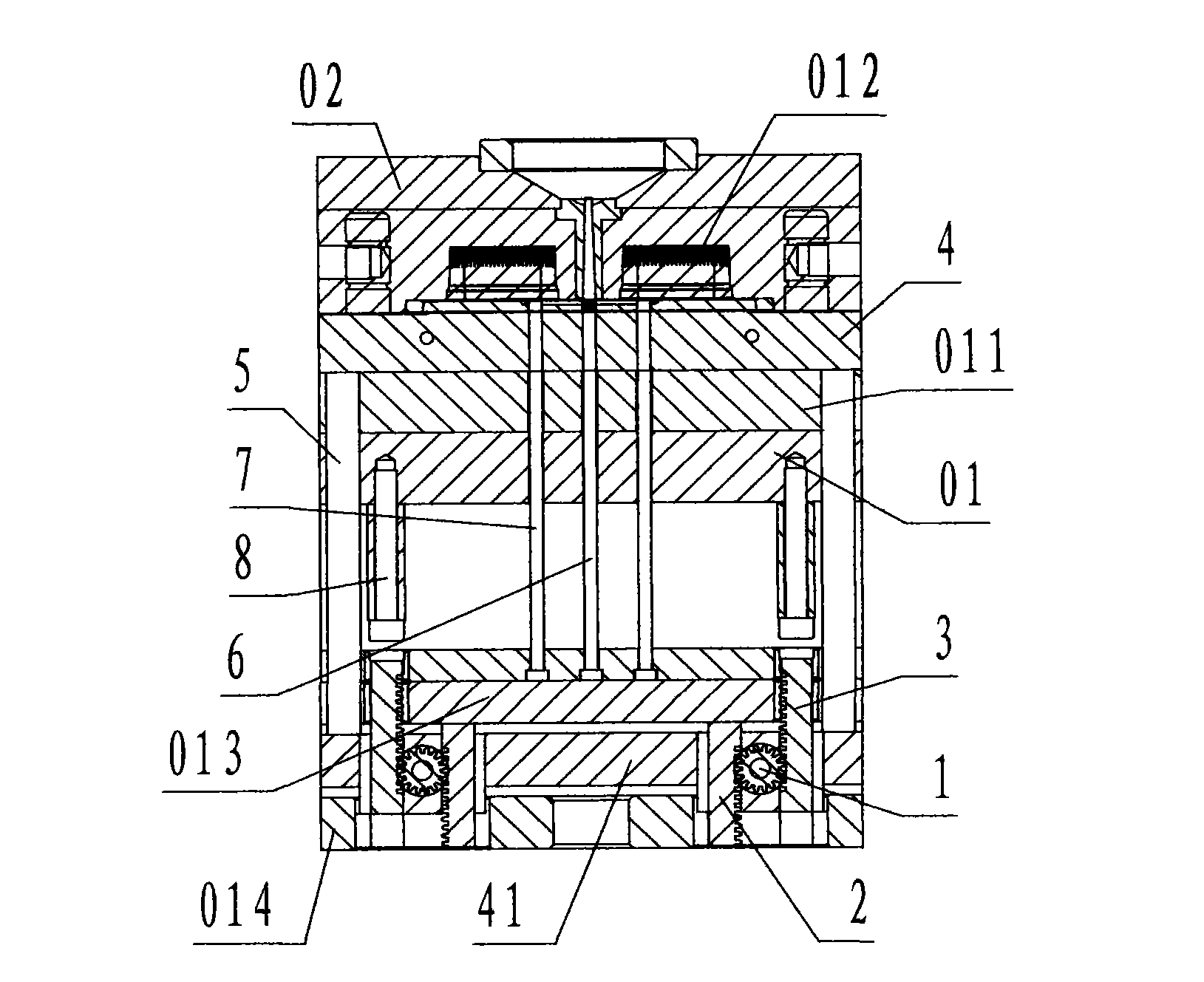

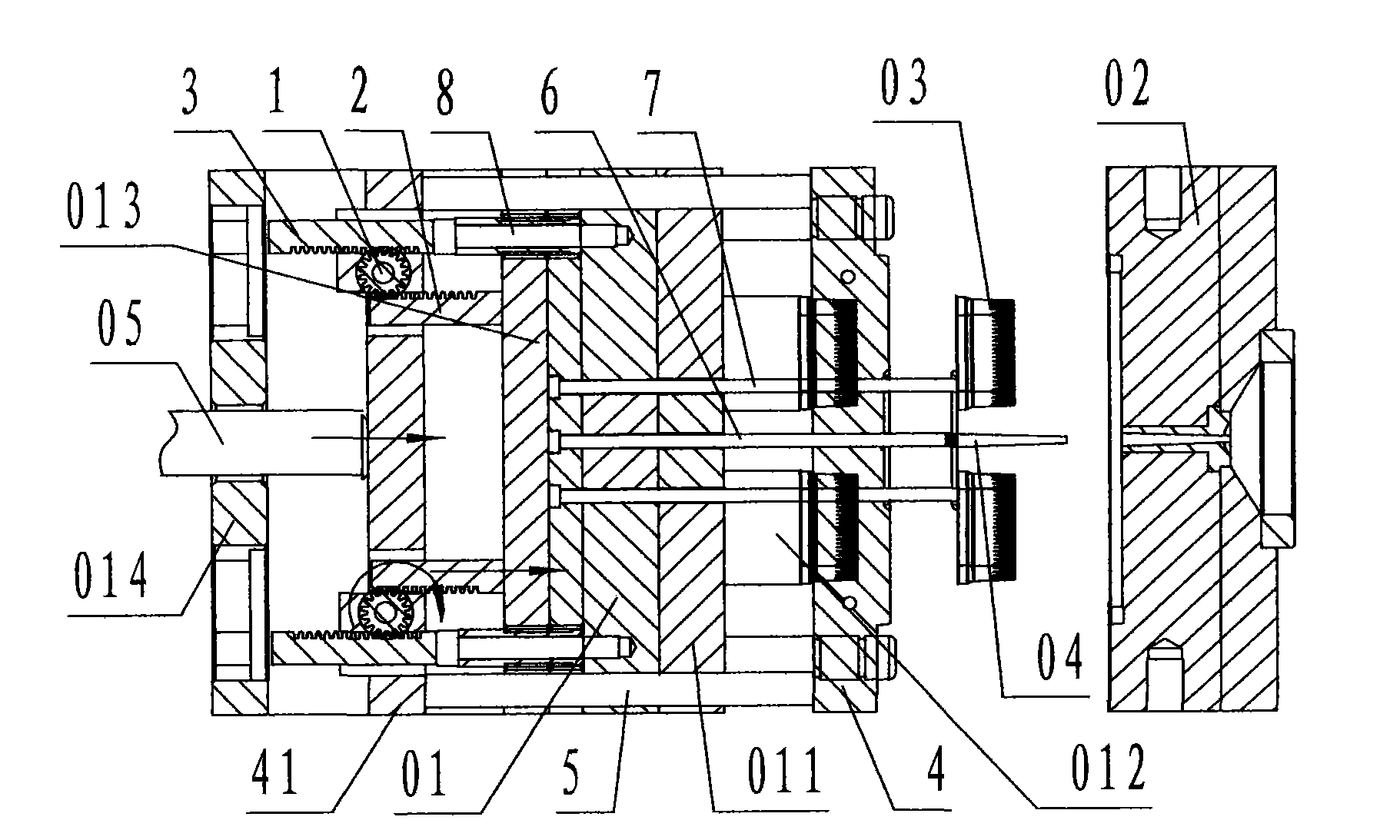

[0017] refer to figure 1 , figure 2 , a rack-type double-speed secondary ejection device of the present invention, including a gear 1, a top plate rack 2, a sliding rack 3, a push plate 4, a push plate 41, a push plate top return rod 5, and a material head pull ejector rod 6. Product ejector rod 7 and positioning rod 8, wherein: the gear 1 is a cylindrical spur involute steel gear; the top rack 2 is a rectangular bar with trapezoidal teeth on the side of a long side Shaped steel member; The sliding rack 3 is a rectangular elongated steel member with trapezoidal teeth on the long side, and the opposite side of the sliding rack 3 is provided with teeth. T-shaped guide rails in the up and down direction; the push plate 4 is a rectangular plate-shaped steel member, and the push plate 4 is provided with a through hole that is longitudinally slidably matched with the lower profile of the core 012 of the movable mold, and the push plate 4 is used The purpose of pushing away the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com