Built-in burglar-proof padlock for electromobile

A technology for electric vehicles and anti-theft locks, applied in the field of anti-theft locks, can solve problems such as failures, deceleration motors burnt, lifting shafts stuck, etc., and achieve the effect of protecting normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

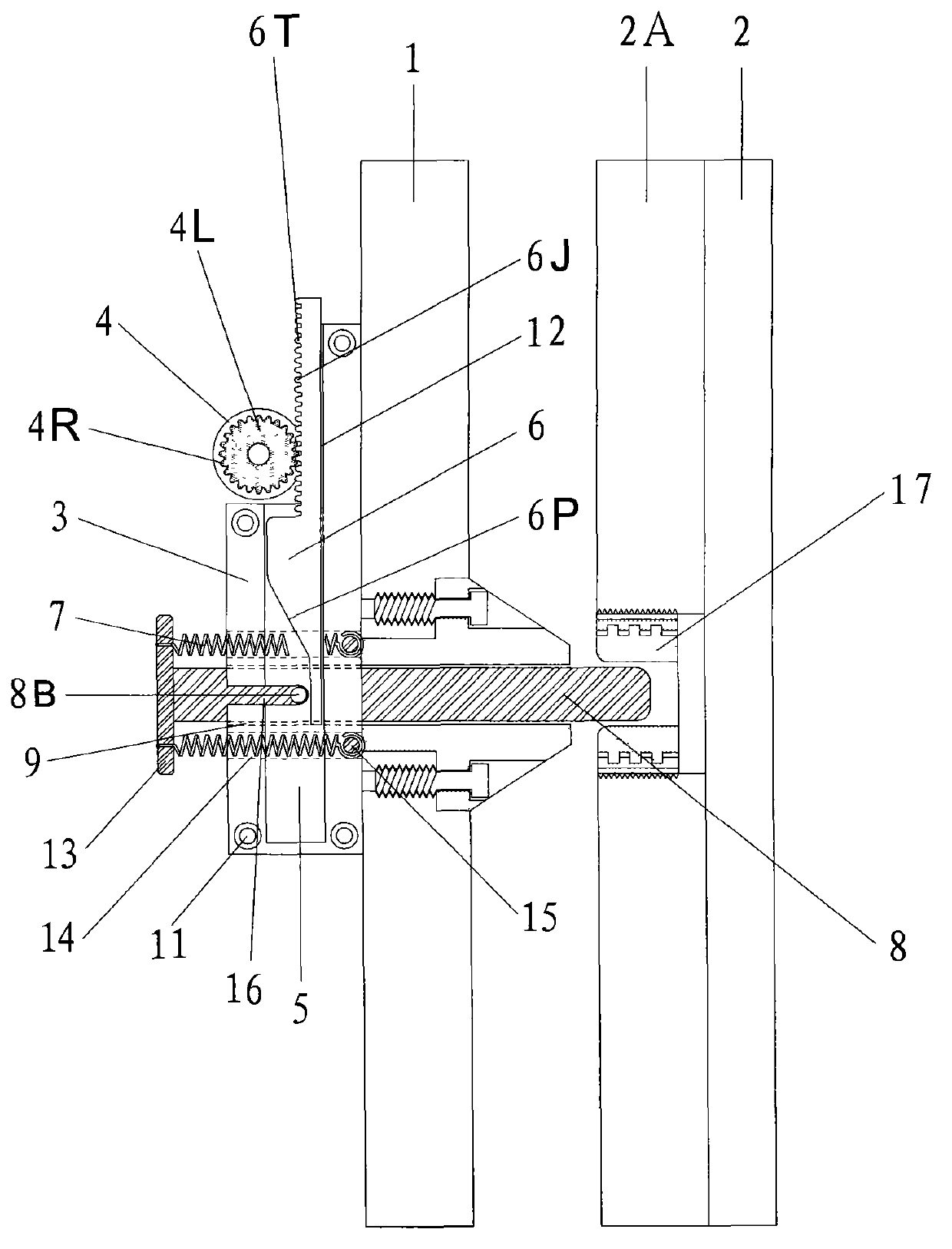

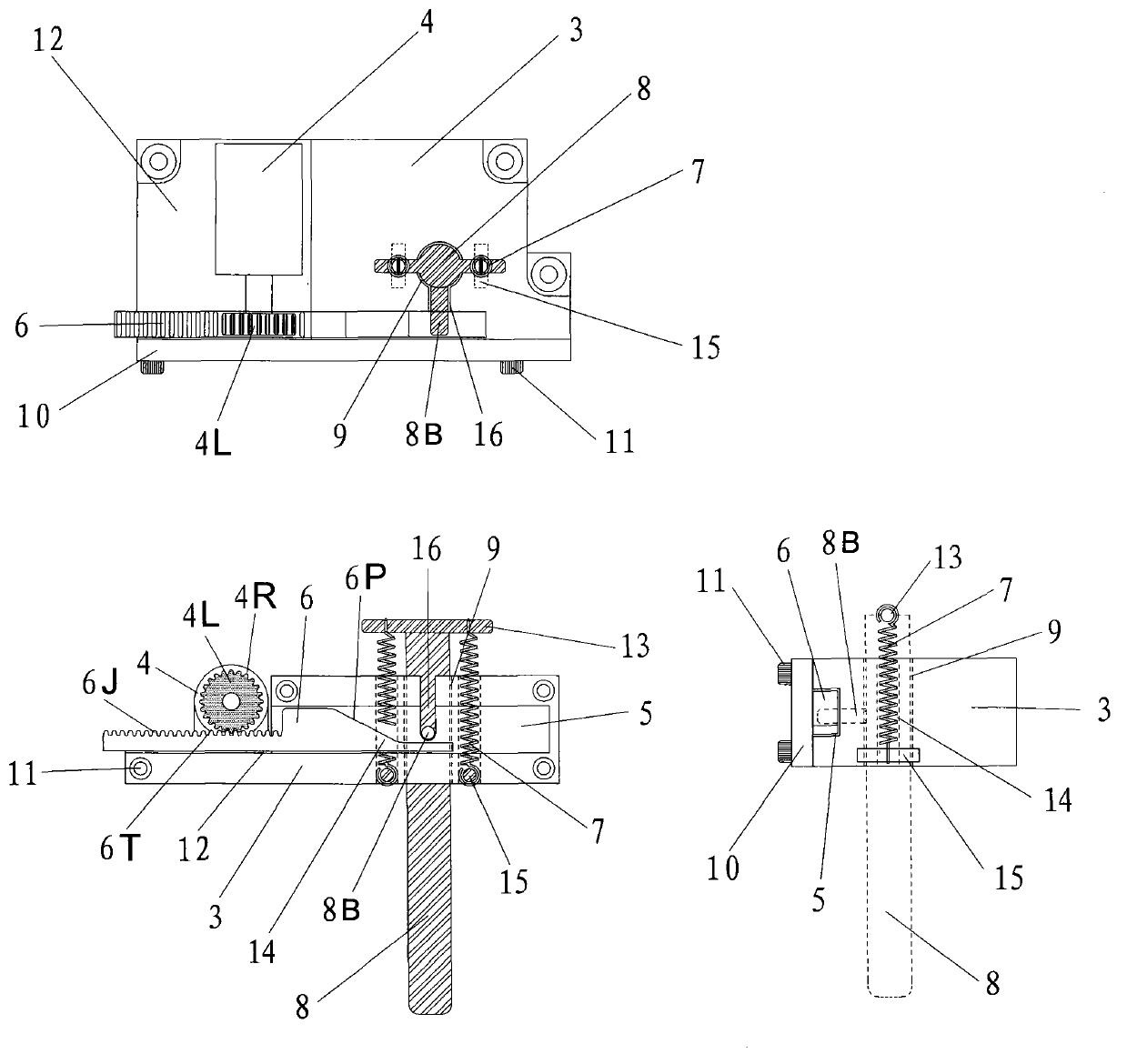

[0011] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0012] As shown in the figure; the motor stator (1) is provided with an integral lock assembly (3), and the integral lock assembly (3) includes; a geared motor (4), a groove (5), a rack (6), and an extension spring (7), lock pin (8), lock pin positioning through hole (9), positioning plate (10) and screw (11), and the described overall lock assembly (3) is provided with a laterally installed geared motor (4) Steps in the concave part (6T), the front end of the geared motor (4) is provided with a gear (4L), the circumference of the gear (4L) is provided with gear teeth (4R), and the drive of the gear teeth (4R) is set on the side edge of the overall lock assembly (3) The rack (6) in the groove (5) engages and slides back and forth, and the sliding stroke of the rack (6) is controlled by the reduction motor (4). The sliding of the trapezoidal inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com