Intelligent vacuum inflating packaging machine

An inflatable packaging, intelligent technology, applied in the direction of pressurized/vaporized packaging, etc., can solve the problems of uncontrolled bag shape, large consumption of inert gas, increased pollution risk, etc., achieve high-quality vacuum effect and shorten work Time, the effect of reducing the inflation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a detailed description of the technical solutions of the present invention through the accompanying drawings.

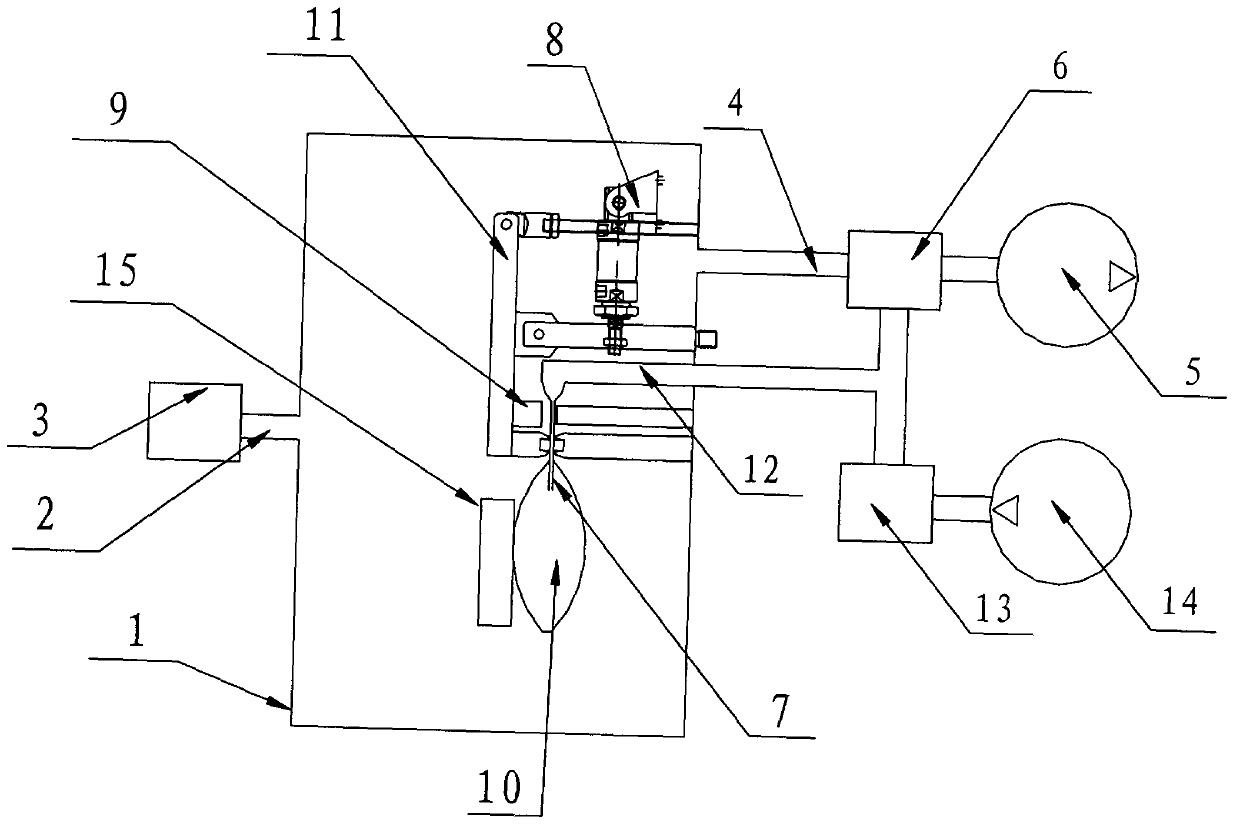

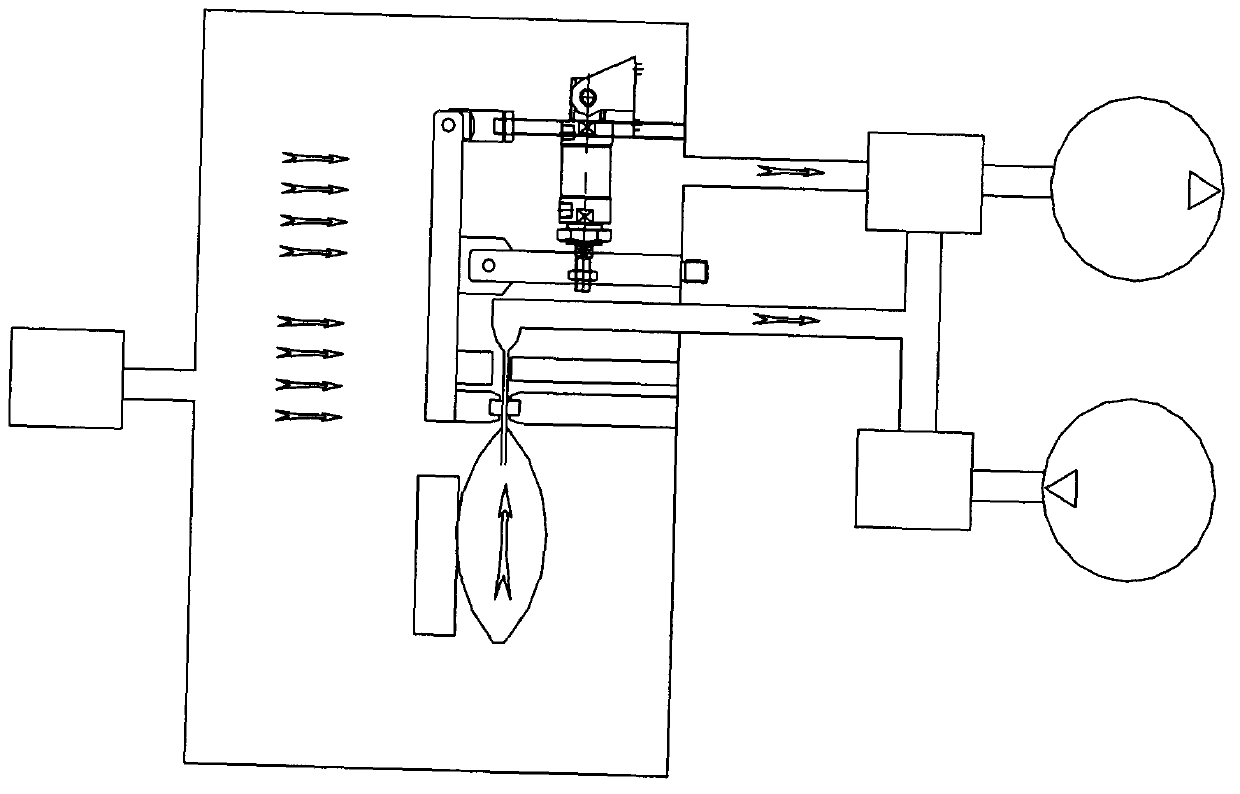

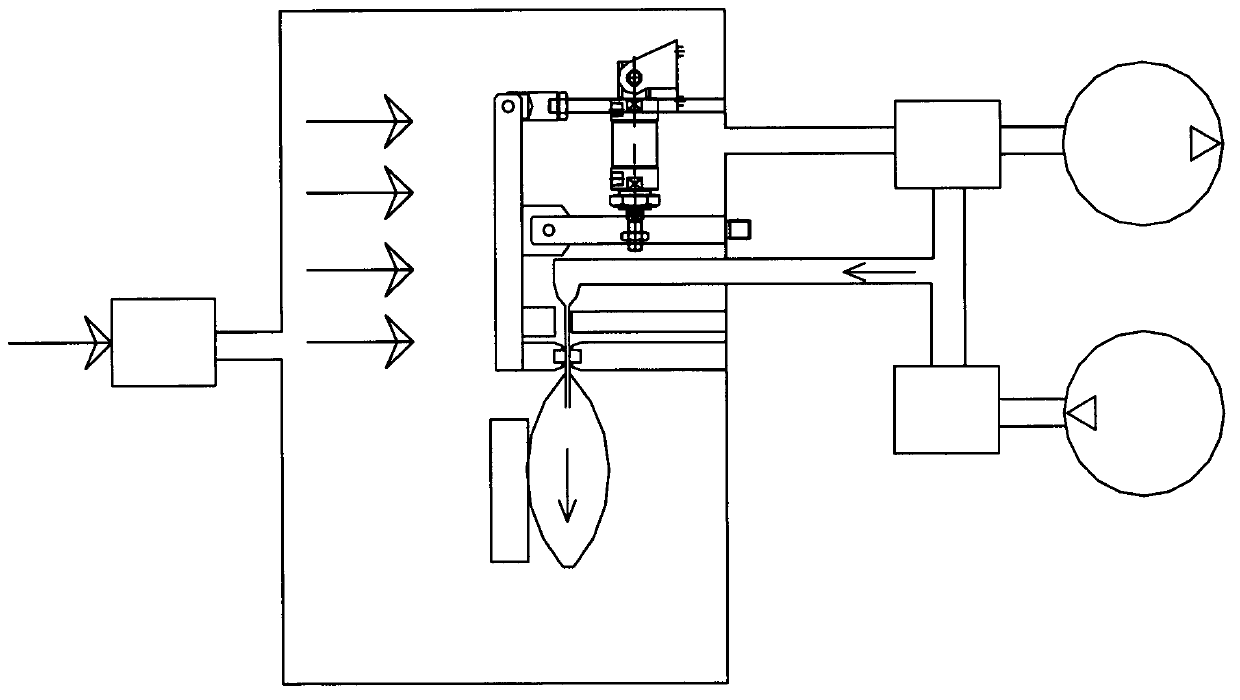

[0020] like figure 1 As shown, the intelligent vacuum inflation packaging machine of the present invention includes a chamber 1 and a packaging device and a packaging bag 10 arranged in the chamber 1. One side of the chamber 1 is connected with a trachea 2, and the trachea 1 2 is provided with an exhaust valve 3, the other side of the chamber 1 is connected with a trachea 2 4, the other end of the trachea 4 is connected with a mechanical pump 5, and the trachea 2 4 is provided with a vacuum valve 6; the packaging device includes The air nozzle 7, the air nozzle device 8 and the sealing device 9, one end of the air nozzle 7 is connected to the packaging bag 10, and the other end is connected to the trachea 3 12, and the trachea 3 12 is connected to the vacuum valve 6 and passed through the inflation valve 13 is connected to the inert gas tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com