Thin film flattening roller

A technology of roller and film, applied in the field of film flattening roller, to achieve the effect of solving wrinkles, low cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

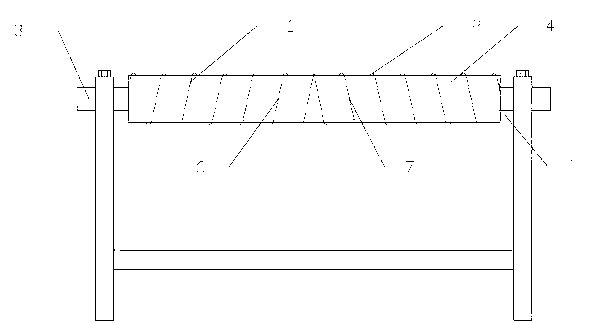

[0011] Such as figure 1 , figure 2 As shown, a film flattening roller provided in this embodiment includes a roller 1, ribs 2 and a rotating shaft 3. Ribs 2 are provided on the surface 4 of the roller 1, and ribs 2 are arranged at both ends 5 of the roller 1. There are rotating shaft 3. In order to make the film product pass smoothly and smoothly, the rib 2 is composed of a left spiral rib 6 and a right spiral rib 7, and the left spiral rib 6 and the right spiral rib 7 are distributed on the surface of the drum 1 in a spiral shape 4 on. Preferably, the rib 2 is welded on the surface 4 of the drum 1 by a round steel wire 8 .

Embodiment 2

[0013] In this embodiment, under the same conditions as in Embodiment 1, the ribs 2 are welded on the surface 4 of the drum 1 by ten round steel wires 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com