Preparation method of polyurethane acrylate oligomer surface modified silica

A polyurethane acrylic acid and acrylate-based technology, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. The effect of simple operation steps and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

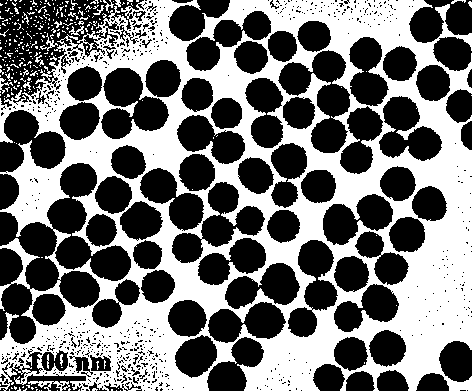

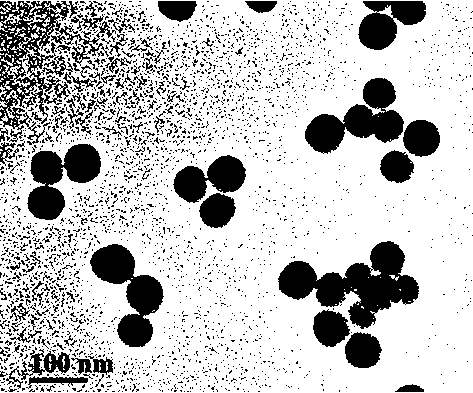

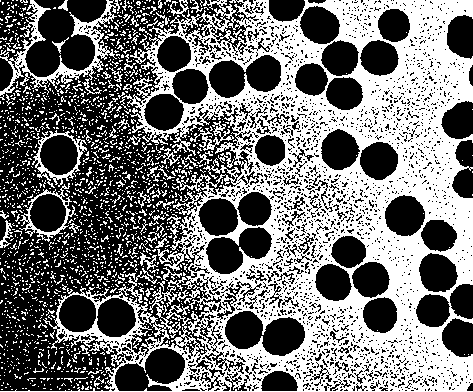

[0022] (1) Synthesis of silica and its modification by sol-gel method: 600 mL of absolute ethanol, 34.8 mL of 28% ammonia water, and Ionized water 11.2mL, heat up to 50°C, then slowly add 22.4mL tetraethyl orthosilicate into the flask, stir and react at 50°C for 24 hours, and obtain a silica ethanol solution (particle size is about 70nm). Take 53mL of silicon dioxide ethanol solution and add it to a 100mL three-necked flask, raise the temperature to 50°C, slowly add 0.2mL of 3-aminopropyltriethoxysilane (APTES) dropwise, stir and react at a constant temperature of 50°C for 24h, then add absolute ethanol Repeated centrifugal washing 3 times, ultrasonically dispersed in dehydrated acetone to obtain silane-modified silica.

[0023] (2) Synthesis of isocyanate-terminated polyurethane acrylate oligomers: Add 0.055mol (12.4g) isophorone diisocyanate (IPDI) into a 100mL three-necked flask equipped with a stirrer, thermometer and reflux condenser , heated to 50°C, then slowly added 0...

Embodiment 2

[0026] (1) Synthesis of silica and its modification by sol-gel method: Add 600 mL of absolute ethanol, 34.8 mL of ammonia water, and 11.2 mL of deionized water into a 1000 mL three-necked flask equipped with a stirrer, thermometer and reflux condenser in sequence , raised the temperature to 50°C, then slowly added 22.4 mL of tetraethyl orthosilicate into the flask, stirred at 50°C for 24 hours, and then obtained the silica ethanol solution (particle size about 70nm). Take 53mL of silicon dioxide ethanol solution and add it to a 100mL three-neck flask, raise the temperature to 50°C, slowly add 0.2ml of 3-aminopropyltriethoxysilane (APTES) dropwise, stir and react at a constant temperature of 50°C for 24h, then add absolute ethanol Repeated centrifugal washing 3 times, ultrasonically dispersed in dehydrated acetone to obtain silane-modified silica.

[0027] (2) Synthesis of isocyanate-terminated polyurethane acrylate oligomers: Add 0.055mol (12.4g) isophorone diisocyanate (IPDI)...

Embodiment 3

[0030] (1) Synthesis of silica and its modification by sol-gel method: Add 600 mL of absolute ethanol, 34.8 mL of ammonia water, and 11.2 mL of deionized water into a 1000 mL three-necked flask equipped with a stirrer, a thermometer and a reflux condenser in sequence , raised the temperature to 50°C, then slowly added 22.4 mL of tetraethyl orthosilicate into the flask, stirred at 50°C for 24 hours, and then obtained the silica ethanol solution (particle size about 70nm). Take 53mL of silicon dioxide ethanol solution and add it to a 100mL three-necked flask, raise the temperature to 50°C, slowly add 0.2ml of 3-aminopropyltriethoxysilane (APTES) dropwise, stir and react at a constant temperature of 50°C for 24 hours, then repeat with absolute ethanol Wash by centrifugation for 3 times, and ultrasonically disperse into dehydrated acetone to obtain silane-modified silica.

[0031] (2) Synthesis of isocyanate-terminated polyurethane acrylate oligomers: Add 0.055mol (12.4g) isophoro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap