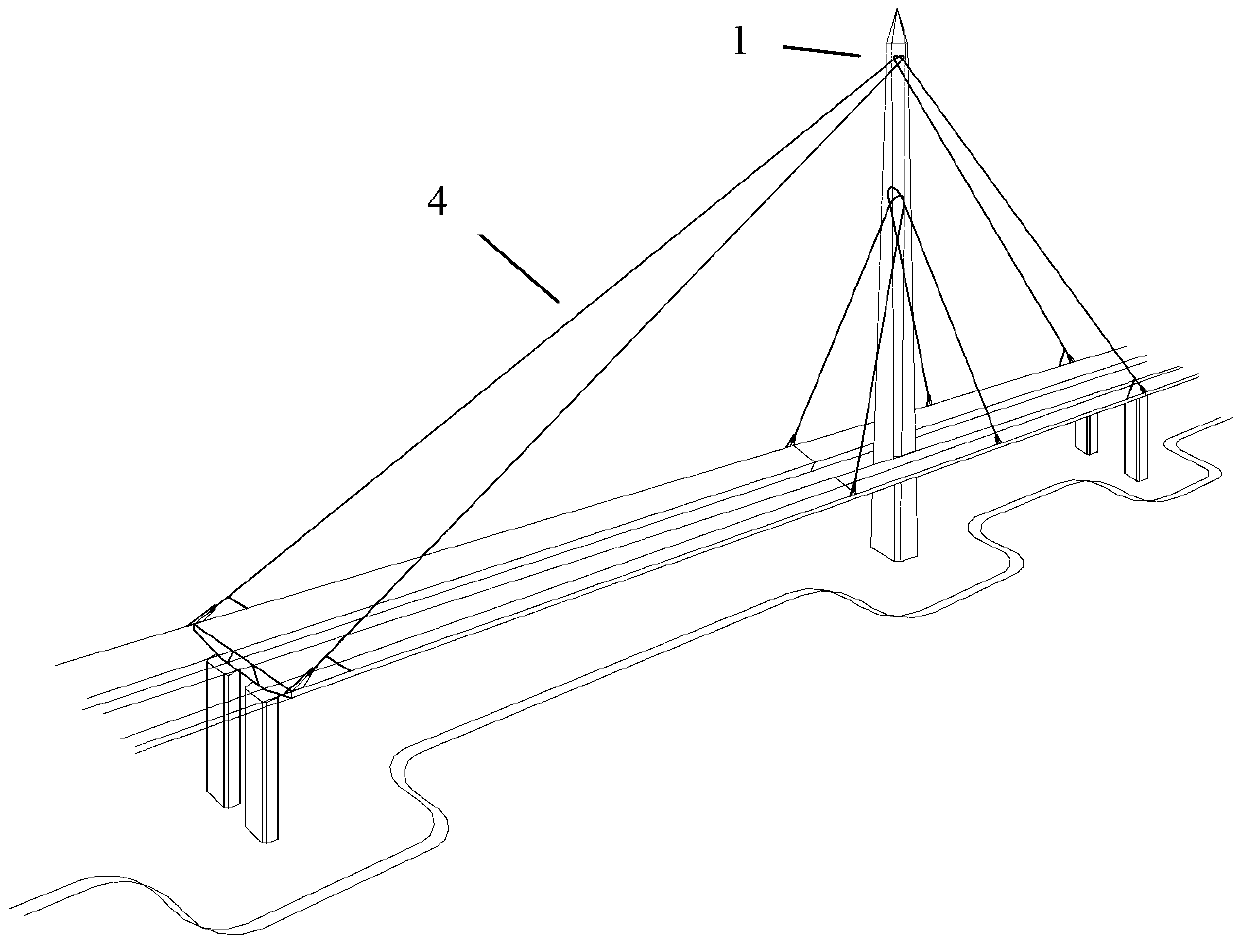

Pulling-rope diverter for inclination of rope tower

A steering gear and saddle body technology, which is applied in the field of cable steering gear, can solve problems such as the splitting force of the cable tower wall, affecting the safety of the cable tower, and difficulties in processing and manufacturing, and achieve the elimination of the difficulty of cable specification restrictions, installation and maintenance. Simple positioning, avoiding the effect of pulling force and splitting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

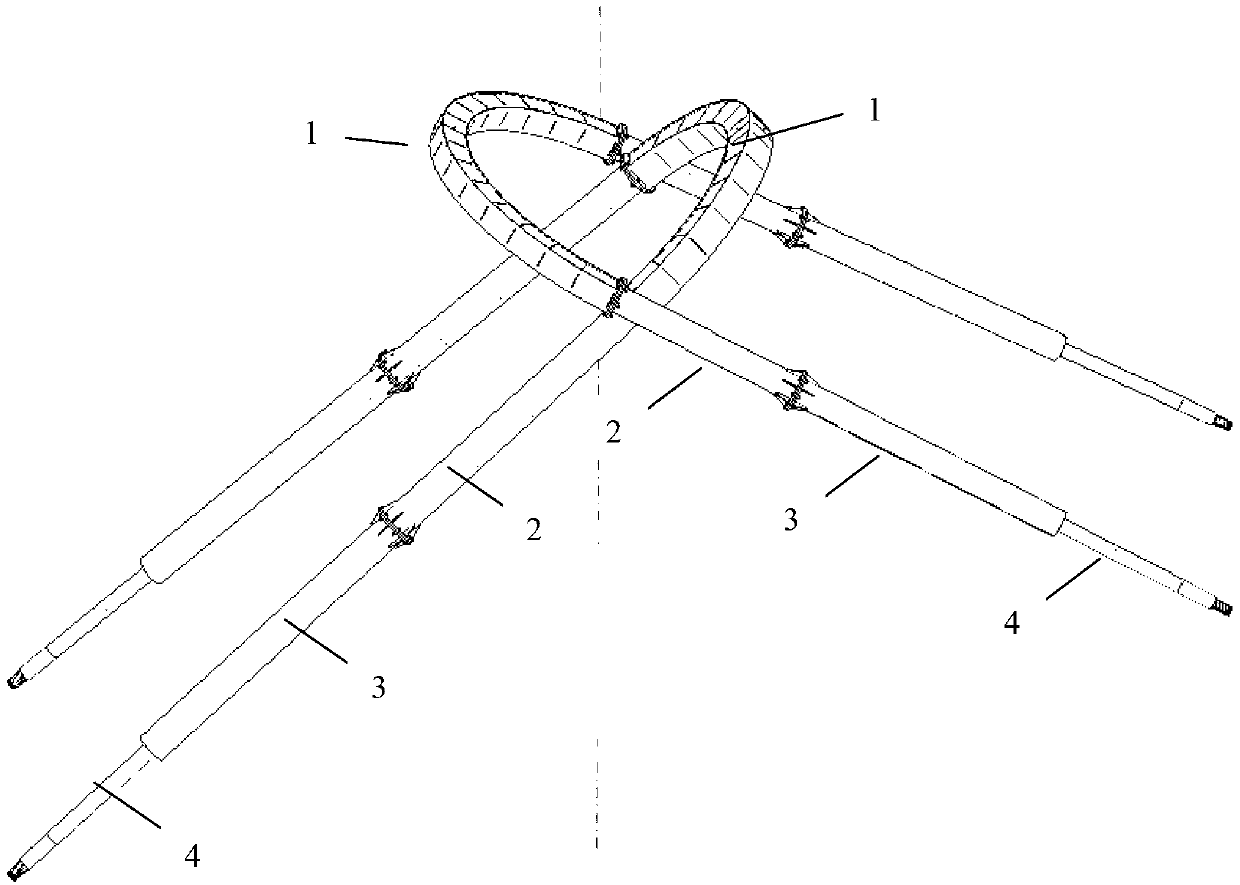

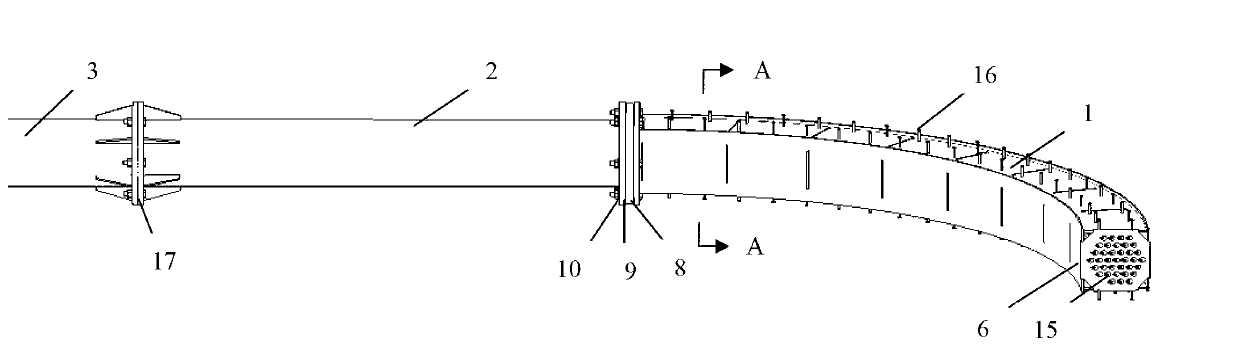

[0021] Such as Figure 3-12 As shown in the figure, a cable diverter used for tilting the cable tower includes a saddle body composed of four steel plates welded up, down, left, and right, and a cable strand transition tube 3 connected by a transition flange. The splitting tube fixed by the positioning plate 6 is filled with C50 micro-expansion concrete 18, the distance between the positioning plates is 500mm, and the two sides corresponding to the saddle body are provided with shear nails 16.

[0022] The splitting tube arranged in the saddle body 1 adopts a raindrop-shaped splitting tube 5, and the raindrop-shaped splitting tube is formed by pressing a stainless steel round tube with an outer diameter of 32mm and a wall thickness of 1.5mm, and its minimum radius is 2000mm. Passing through and clamping the unbonded steel strand 15 of the cable stay, the V-shaped section at the lower part of the raindrop-shaped wire splitting tube is in contact with the strands, and the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com