Novel hopper

A hopper and novel technology, applied in the field of hopper, can solve the problems of low labor efficiency, high labor intensity and labor, and achieve the effects of simple structure, large amount of goods and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

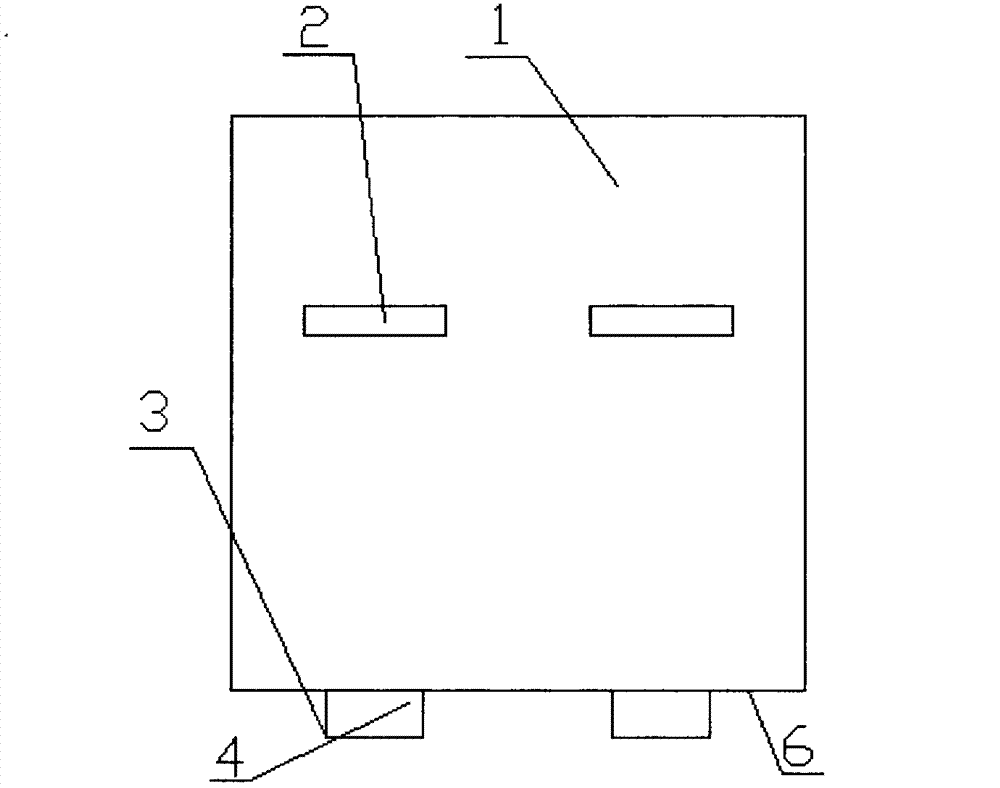

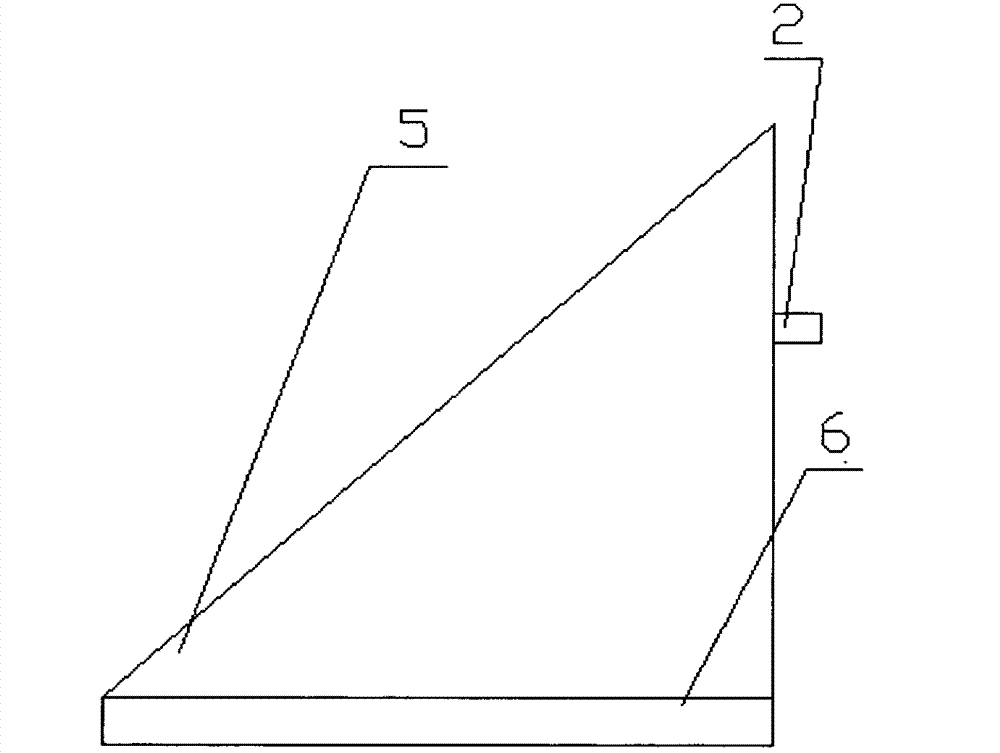

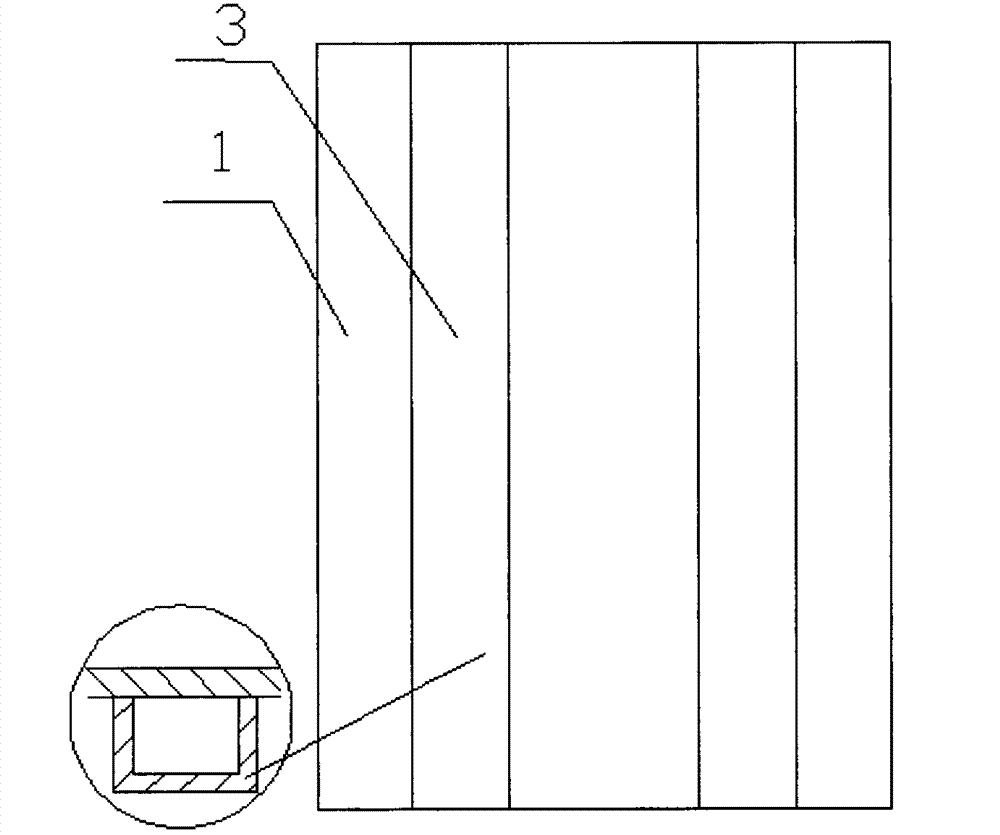

[0015] The preferred embodiment of the present invention is like this, with reference to Figure 1-Figure 4 The whole feature is: for example, cut a square iron box in half diagonally, then install guide rails on the bottom surface, install hanging ears on the back plate, insert the shovel head of the forklift into the guide rail groove, and insert the hopper into the material pile (corn, soybean meal, etc.) class), drive the cart to pull away the material grains, lift the hanging lugs, and unload the material. Specifically: the backboard (1) is vertically connected to the baseboard (6), and both sides have inclined boards (5) clamping the backboard (1) to be welded and fastened into a hopper shape, and installed on the outer wall surface of the backboard (1). Hanging lug (2), the guide rail (3) of two guide sleeve types is adorned under base plate (6), and guide rail (3) has guide rail groove (4) and is installed and welded with reinforcing rib at the inboard limit of hopper....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com