Multi-stage bearing method based onincreaseof ship transportation area and total load

A multi-level, area-based technology, applied in ship accessories, ship safety, transportation and packaging, etc., can solve problems such as increasing ship area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

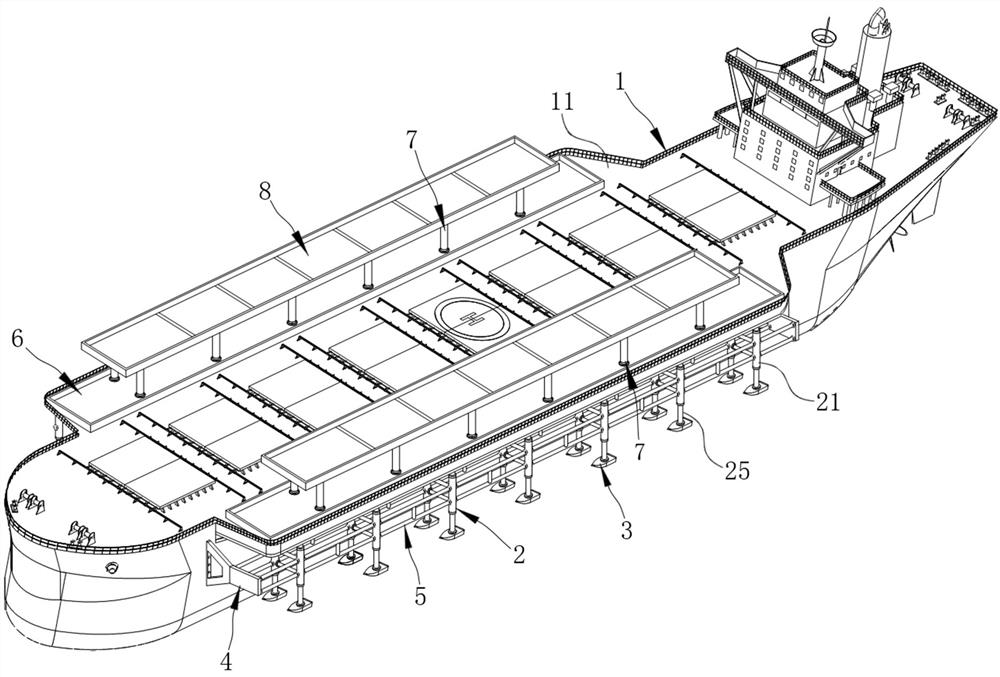

[0050] Such as figure 1 As shown, an auxiliary shipping deck 11 is extended on both sides of the hull structure 1 ; the auxiliary shipping deck 11 is used as a structural basis for improving the shipping area and total load of the hull structure 1 .

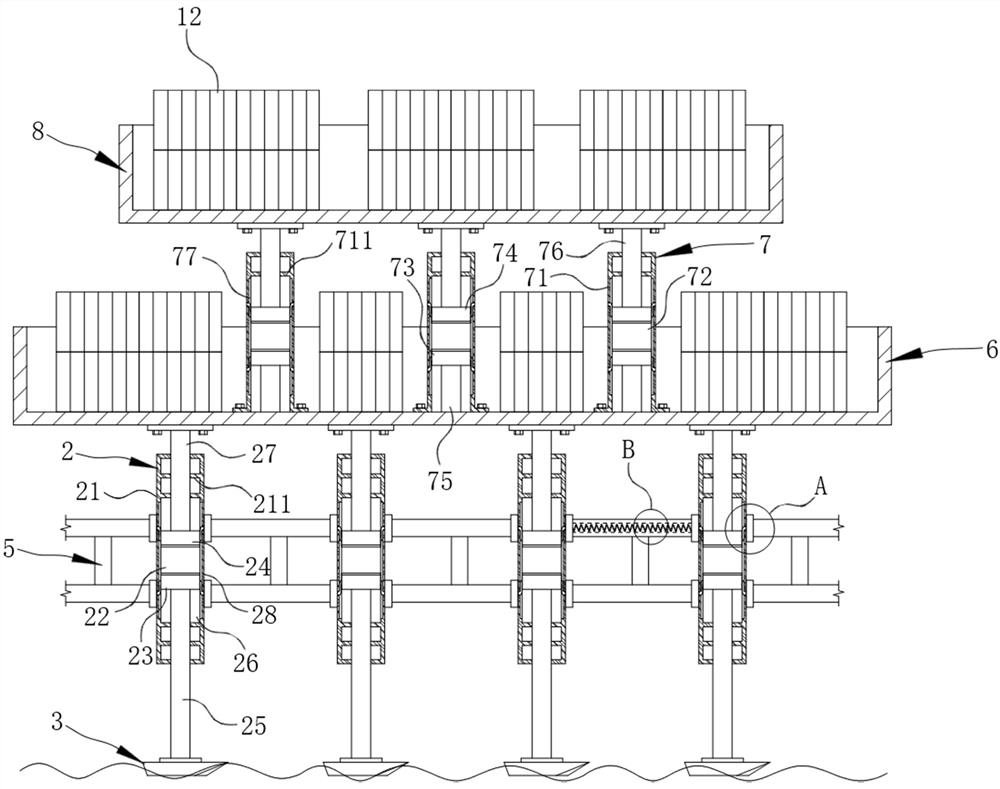

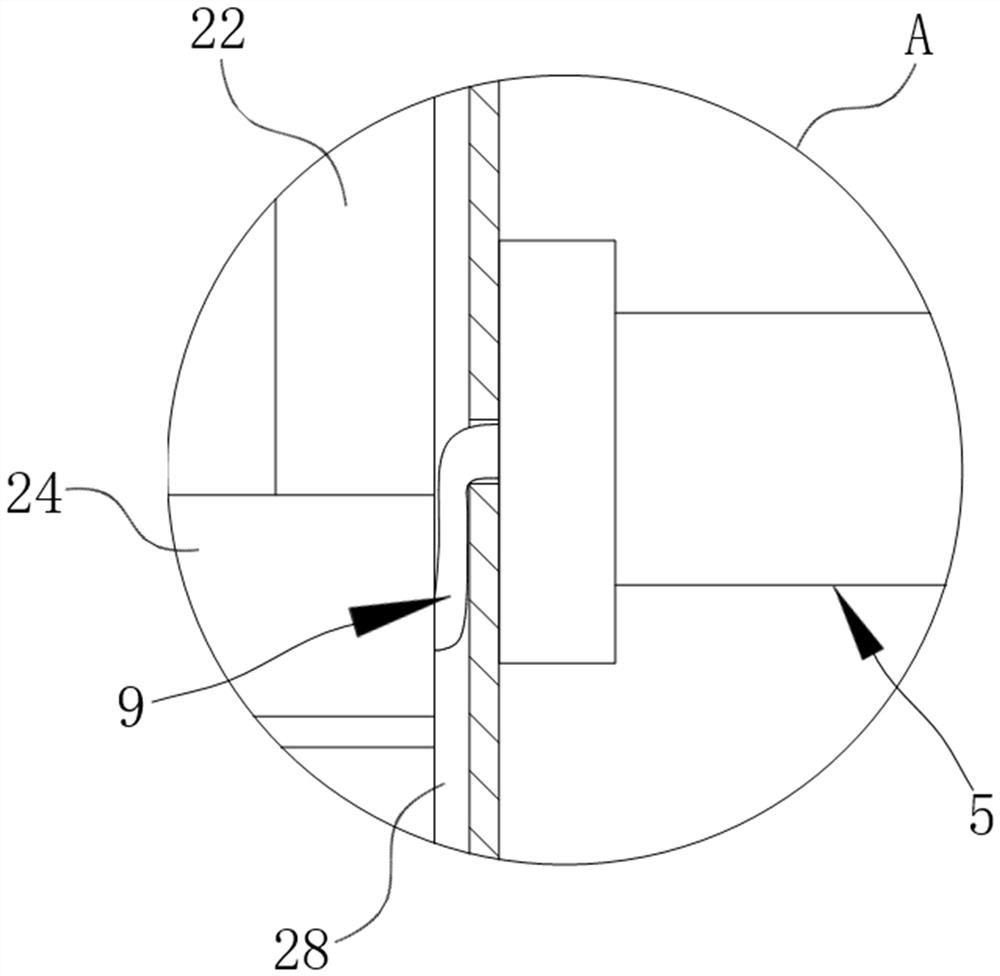

[0051] Please refer to Figure 1 to Figure 2 The front and rear ends of the two side walls of the hull structure 1 are fixedly connected with one of the fixed mounting frames 4 respectively, and the two fixed mounting frames 4 of the same side walls are fixedly connected with the fixed mounting frames 4. Position the connecting frame part 5 as described above. There are several first conductive support parts 2, and several first conductive support parts 2 are all fixedly arranged on the positioning connecting frame part 5, so as to be jointly carried by several first conductive support parts 2. Acting on one first shipping pallet 6, while effectively increasing the shipping area, it can also effectively increase the load capaci...

Embodiment 2

[0064] In embodiment 2, for the same structure as in embodiment 1, give the same symbol, omit the same description, embodiment 2 has made improvement on the basis of embodiment 1, as Figure 5 As shown, the end of the second foundation support rod 75 that is away from the second foundation electromagnet 73 along its extension direction passes through the first shipping pallet 6 and is fixedly connected with the floating body bearing part 3, the The floating body bearing part 3 floats on the water surface, and is used to directly support the second foundation support rod 75 and the second foundation electromagnet 73 effectively by means of the water buoyancy force received by the floating body bearing part 3; The inner wall of the cavity is also fixedly provided with a second limiting block 711 corresponding to the second basic support rod 75, and the second limiting block 711 is slidably fitted with the second basic supporting rod 75, The sliding stability of the second founda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com